What is Woven Steel Mesh and Its Applications in Various Industries?

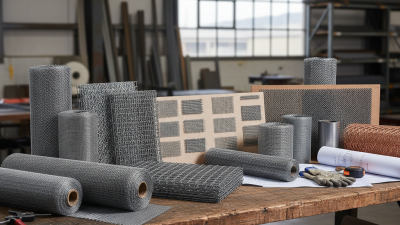

Woven steel mesh is a versatile material used across various industries. It consists of interwoven steel wires that create a durable and strong framework. This mesh is lightweight, yet it provides excellent strength and flexibility. Manufacturers appreciate its ability to withstand harsh environments, making it ideal for construction and mining applications.

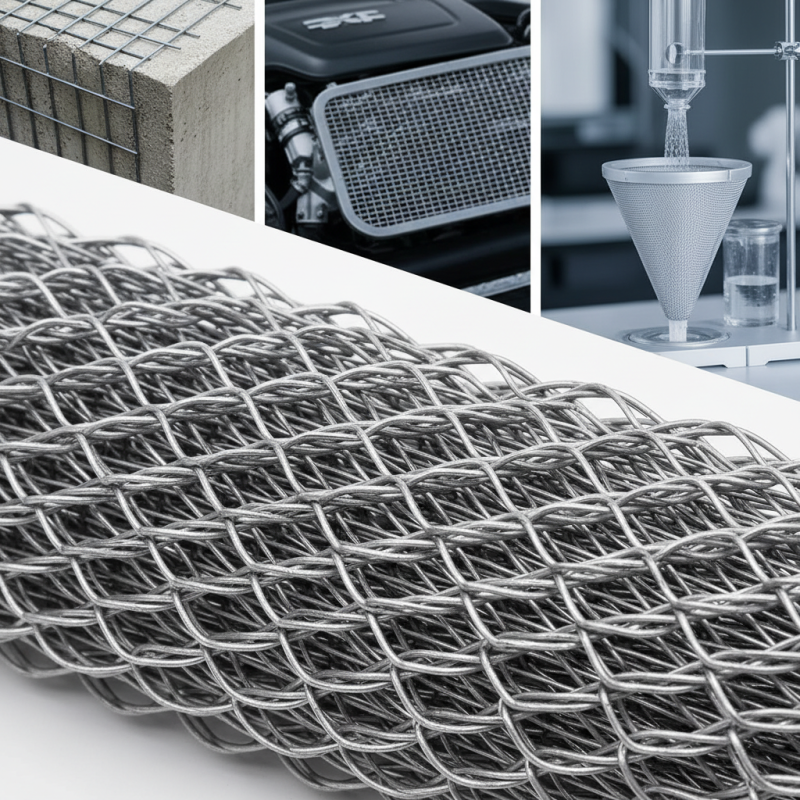

In construction, woven steel mesh is commonly used for reinforcing concrete. It enhances the structural integrity of buildings and other structures. In the automotive industry, it serves as a protective barrier for engine components. Additionally, woven steel mesh has uses in filtration systems, offering reliable separation of particles in liquids and gases.

Despite its benefits, there are areas for improvement. For instance, the manufacturing process can sometimes lead to variations in quality. Understanding these nuances can help industries better utilize woven steel mesh. By addressing these challenges, we can enhance its applications even further.

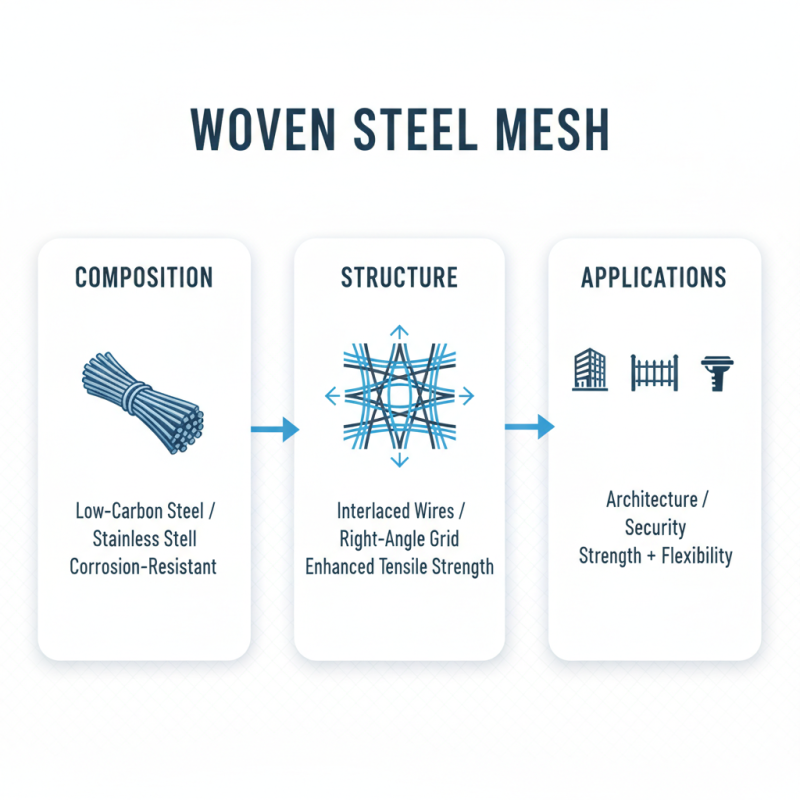

What is Woven Steel Mesh? Definition and Composition Overview

Woven steel mesh is a versatile material made from interlaced steel wires. It combines strength with flexibility, making it ideal for various applications. Typically, this mesh is composed of low-carbon steel or stainless steel, which offers durability and resistance to corrosion. The weaving process involves crossing wires at right angles, creating a grid-like pattern. This structure enhances the overall tensile strength of the mesh.

One common application of woven steel mesh is in construction. It is often used for reinforcing concrete slabs and walls. This provides added structural support and ensures durability. Additionally, in the manufacturing sector, woven steel mesh serves as a filter medium. It can efficiently separate particles of different sizes in various fluids. Its adaptability means it also finds use in architectural designs, such as facades or partitions.

**Tip:** Before purchasing woven steel mesh, consider the specific application. Different projects may require varying wire diameters and mesh sizes.

Another area where woven steel mesh excels is in garden fencing. It acts as a barrier to keep out pests while allowing airflow and light. However, not all woven steel mesh is suitable for outdoor use. Make sure to select a type with proper corrosion resistance.

**Tip:** Regular maintenance can extend the life of woven steel mesh. Inspect for rust and wear, especially in outdoor settings.

Key Properties of Woven Steel Mesh: Strength, Durability, and Flexibility

Woven steel mesh is a versatile material used in many industries. Its key properties include strength, durability, and flexibility. These features make it suitable for a range of applications from construction to filtration.

Strength is crucial for woven steel mesh. It can withstand heavy loads and harsh conditions. This strength comes from its unique weaving pattern. The mesh is often used in industrial barriers and reinforcement. However, the production process can sometimes lead to variability in strength. Quality control is essential to ensure reliability.

Durability is another important property. Woven steel mesh resists corrosion and wear over time. It performs well in outdoor applications, especially in harsh environments. Yet, it is not immune to damage. Improper handling can cause deformation or failure. Flexibility allows for different shapes and sizes, making it adaptable. However, this flexibility can also lead to instability if not properly designed. Balancing these factors is important in successful applications.

Industries Utilizing Woven Steel Mesh: Construction, Automotive, and Aerospace

Woven steel mesh finds a wide range of applications in various industries. In construction, it serves as essential reinforcement. Builders often use it in concrete structures for added strength. The mesh improves durability, allowing structures to withstand harsh conditions. However, one must ensure correct sizing. Inadequate dimensions can lead to weaknesses. The precision of the weaving process plays a crucial role in overall performance.

The automotive industry also benefits from woven steel mesh. It is frequently used in filters, which maintain engine efficiency. Quality control in manufacturing is vital, as small defects can lead to significant issues. Mesh with inconsistent wire thickness may not perform well in varied environments. Engineers must evaluate its suitability during design stages.

In aerospace, woven steel mesh serves vital roles in structural components. Its lightweight nature aids in fuel efficiency. However, manufacturers must consider the trade-off between strength and weight. Flaws in the mesh could compromise safety. Ongoing analysis of performance and quality is necessary. This ensures that woven steel mesh meets the demanding specifications of the industry.

Applications of Woven Steel Mesh in Various Industries

The above bar chart illustrates the various applications of woven steel mesh across different industries. The construction industry utilizes woven steel mesh the most, followed by the automotive and aerospace industries. Other sectors like mining and filtration also make use of woven steel mesh, although to a lesser extent.

Market Trends: Growth Rate and Demand for Woven Steel Mesh Worldwide

Woven steel mesh has gained significant traction across several industries. The global demand for this product is on the rise, driven by its versatile applications. Construction, agriculture, and manufacturing sectors heavily utilize woven steel mesh. Its strength and durability make it a preferred choice for filtration systems and security fencing.

Market trends indicate a steady growth rate. Analysts predict increasing adoption of woven steel mesh in infrastructure projects. The construction industry's focus on sustainable materials is also a contributing factor. However, challenges like fluctuating raw material costs may affect market stability. Awareness of these fluctuations is crucial for businesses considering long-term investments.

Tips: Evaluate your specific needs before purchasing woven steel mesh. Understand the material's properties to ensure it fits your application. Research market trends periodically. Be proactive in adapting to changes that could impact pricing or availability.

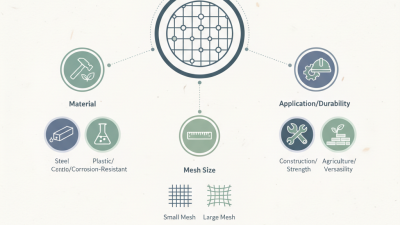

Comparison of Woven Steel Mesh with Other Steel Mesh Types and Materials

Woven steel mesh is widely used in different industries.

It stands out for its durability and versatility.

However, how does it compare to other steel mesh types?

When we look at welded steel mesh, it has a rigid structure.

This feature provides strong support but limits flexibility.

In contrast, woven steel mesh offers a balance of strength and adaptability.

This makes it suitable for both industrial and decorative applications.

For example, woven mesh can be found in architectural designs.

It's not as visually appealing as some alternatives, yet it serves a practical purpose.

Another comparison involves plastic mesh.

While plastic is lightweight, it lacks the strength of metal.

Woven steel mesh withstands higher pressures and extreme conditions.

However, it can rust if not properly coated.

Maintenance is a key consideration. Each type of mesh has its own advantages and limitations.

Understanding these differences is crucial for making informed choices in various applications.

Related Posts

-

How to Choose the Right Wire Mesh for Your Project Needs

-

How to Choose the Best Wire Mesh Products for Your Project Needs

-

How to Choose the Right Wire Mesh Products for Your Project Needs

-

10 Essential Tips for Choosing the Right Metal Wire Mesh for Your Project

-

How to Choose the Best Wire Mesh for Your Home and Garden Projects

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs