Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

Woven mesh has emerged as a critical component across multiple industries, showcasing remarkable versatility and adaptability. According to a recent market research report by Grand View Research, the global market for woven mesh materials is projected to reach $8.4 billion by 2025, driven by heightened demand in sectors such as construction, automotive, and filtration. The unique properties of woven mesh, including strength, flexibility, and lightweight design, facilitate innovative applications ranging from architectural facades to advanced filtration systems.

Furthermore, a study by MarketsandMarkets highlights that the increasing emphasis on sustainable materials is pushing manufacturers to explore eco-friendly woven mesh solutions. As industries continue to evolve, the potential of woven mesh to enhance performance and efficiency remains a focal point, heralding a new era of innovation that transforms traditional manufacturing processes.

Furthermore, a study by MarketsandMarkets highlights that the increasing emphasis on sustainable materials is pushing manufacturers to explore eco-friendly woven mesh solutions. As industries continue to evolve, the potential of woven mesh to enhance performance and efficiency remains a focal point, heralding a new era of innovation that transforms traditional manufacturing processes.

Understanding Woven Mesh: Key Characteristics and Benefits

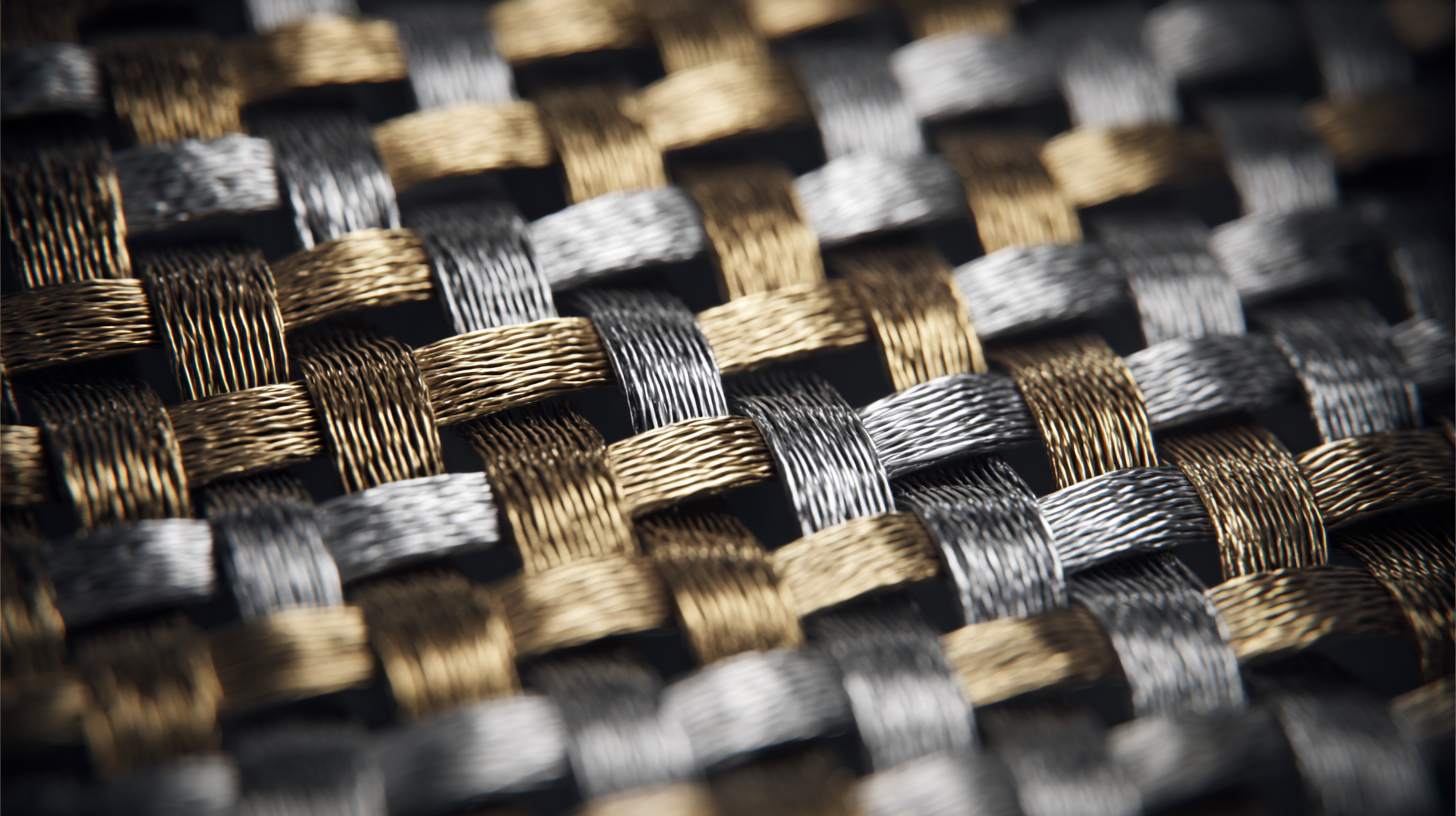

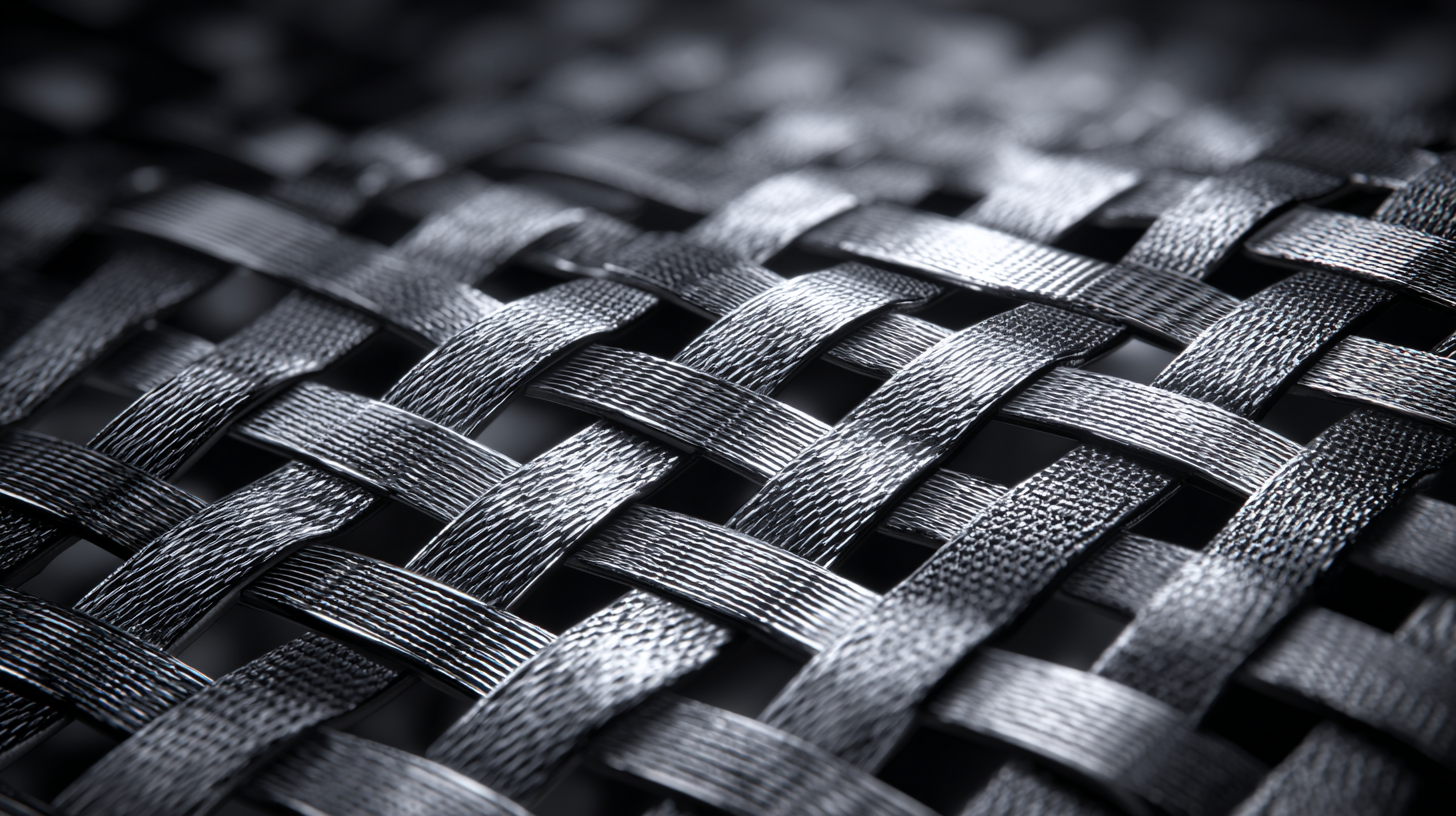

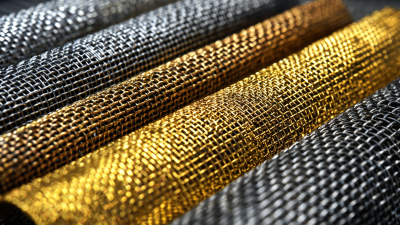

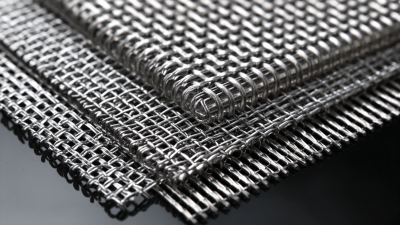

Woven mesh is a versatile material that has gained traction across various industries, thanks to its unique characteristics and numerous benefits. Made by interlacing threads or wires, woven mesh offers exceptional strength while maintaining lightweight properties. This combination makes it ideal for applications in construction, automotive, and even fashion. Its durability and resistance to corrosion further enhance its appeal, ensuring longer product life and lower maintenance costs.

Woven mesh is a versatile material that has gained traction across various industries, thanks to its unique characteristics and numerous benefits. Made by interlacing threads or wires, woven mesh offers exceptional strength while maintaining lightweight properties. This combination makes it ideal for applications in construction, automotive, and even fashion. Its durability and resistance to corrosion further enhance its appeal, ensuring longer product life and lower maintenance costs.

When considering woven mesh for a project, it’s essential to prioritize quality. Look for materials that offer high tensile strength and resistance to environmental factors. Additionally, consider the mesh's aperture size, as it can significantly influence airflow and filtration efficiency.

Tip: Always test samples of woven mesh in real-world conditions to ascertain their performance before committing to a larger order. This step can save time and resources, ensuring that you choose the right mesh type for your specific needs.

Innovative Uses of Woven Mesh in Architecture and Interior Design

The innovative use of woven mesh in architecture and interior design is rapidly gaining traction due to its versatility and aesthetic potential. This material not only provides functional benefits such as durability and flexibility but also offers unique design possibilities that can enhance the aesthetic appeal of various spaces. Recent collaborations in the architectural domain emphasize the integration of modern materials science with design creativity. In this context, woven mesh stands out by enabling designers to create intricate patterns and textures that redefine spatial experiences.

According to a report by the International Interior Design Association, the use of innovative materials like woven mesh is expected to rise by 25% in residential and commercial projects over the next five years. This significant growth reflects a trend where architects are increasingly seeking sustainable and adaptable materials that contribute to both form and function. One intriguing application involves using woven mesh as a dynamic façade element, allowing for natural light filtration while maintaining privacy.

**Tip:** When incorporating woven mesh into your designs, consider how it interacts with light and shadow; this can dramatically alter the ambiance of a space. Additionally, think about its structural applications, which can provide robustness without sacrificing elegance. Emphasizing these aspects can elevate your projects and showcase the potential of woven mesh to its fullest.

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries - Innovative Uses of Woven Mesh in Architecture and Interior Design

| Application Area | Description | Benefits | Materials Used |

|---|---|---|---|

| Architectural Facades | Woven mesh provides aesthetic appeal and functional shading for buildings. | Enhances energy efficiency and visual intrigue. | Stainless Steel, Aluminum, Copper |

| Interior Partitions | Creates flexible and airy dividers in open spaces. | Promotes light diffusion and visual connectivity. | Fiberglass, Polyester, Nylon |

| Ceiling Designs | Adds texture and pattern to ceiling spaces while allowing light passage. | Improves acoustics and visual dynamics. | Aluminum, Steel Wire, Synthetic Fibers |

| Furniture Design | Incorporated into modern furniture for a contemporary look. | Enhances durability and style. | Wood, Metal Frames, Woven Mesh |

Medical Applications of Woven Mesh: From Implants to Bandages

Woven mesh has emerged as a pivotal material in the medical field, showcasing remarkable versatility in applications ranging from implants to bandages. The development of bioglass implants illustrates this innovation, providing a biocompatible solution that can effectively support tissue regeneration. These implants not only enhance healing but also reduce the risk of complications, a crucial factor in surgical procedures. The recent licensing of patents related to bioglass technology underscores the academic and commercial collaboration that drives advancements in medical applications.

Another groundbreaking application of woven mesh is seen in the integration of EDM technology into wound dressing systems. This new technological approach is revolutionizing the way dressing materials are manufactured, offering a streamlined and efficient process that significantly lowers production costs. Such innovations are critical in meeting the growing demand for high-quality medical supplies, ensuring that healthcare providers can deliver effective treatment while minimizing expenses.

Tips: When exploring the use of woven mesh in medical applications, consider the specific needs of the treatment area. For instance, biocompatibility and flexibility are essential for implants, while breathability and sterility are crucial for bandages. Additionally, staying informed about emerging technologies can offer insights into more efficient and cost-effective solutions in medical manufacturing.

Woven Mesh in Industrial Settings: Enhancing Safety and Efficiency

Woven mesh has emerged as a crucial component in various industrial settings, significantly enhancing both safety and efficiency. The adaptability of woven mesh materials allows them to be utilized in a wide range of applications, from protective barriers in construction sites to filtration systems in manufacturing processes. According to a report by MarketsandMarkets, the global industrial mesh market is expected to grow from USD 3.5 billion in 2022 to USD 4.8 billion by 2027, highlighting a burgeoning demand for advanced woven mesh solutions.

In the manufacturing sector, woven mesh plays a vital role in improving workplace safety. By incorporating durable mesh guarding systems, companies can effectively minimize the risk of accidents caused by falling objects or machinery hazards. Moreover, the transparent nature of woven mesh enhances visibility, allowing workers to remain aware of their surroundings, which is particularly important in high-risk environments. A study from the Occupational Safety and Health Administration (OSHA) indicates that the implementation of protective barriers can reduce workplace injuries by up to 20%.

Tips: When selecting woven mesh for industrial applications, consider the specific requirements such as load capacity and environmental conditions. Regular maintenance checks are also critical to ensure that the mesh retains its integrity and performance over time. Additionally, employee training on the proper usage of woven mesh systems can further bolster workplace safety and efficiency.

Sustainable Practices: Eco-Friendly Woven Mesh Solutions in Various Industries

Woven mesh materials are increasingly recognized for their eco-friendly applications across various industries. As sustainability becomes a focal point in manufacturing and production processes, woven mesh solutions offer innovative pathways for reducing environmental impact. According to a report by Smithers Pira, the global market for sustainable textiles, including woven mesh, is projected to reach $250 billion by 2025. This surge is largely driven by growing consumer demand for products that are both functional and environmentally friendly.

In the construction sector, woven mesh is utilized in eco-conscious architectural designs, enhancing structural integrity while minimizing material waste. The use of recycled materials in woven mesh production enables builders to achieve LEED certification, contributing to greener building practices. Additionally, the agriculture industry is leveraging bio-based woven mesh for erosion control and plant protection, as noted in a study by the International Journal of Agricultural Science. These sustainable woven mesh solutions not only provide durability and effectiveness but also align with the global push towards zero-waste initiatives, demonstrating the versatility and necessity of using eco-friendly materials in today’s industries.

Exploring the Versatility of Woven Mesh in Different Industries

This chart illustrates the various applications of woven mesh across different industries, highlighting its innovative uses and sustainable practices. The data showcases the percentage of industry adoption for woven mesh solutions.

Related Posts

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Woven Wire for Your Project Needs

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Exploring the Benefits of Fine Mesh Filters in Sustainable Home Brewing