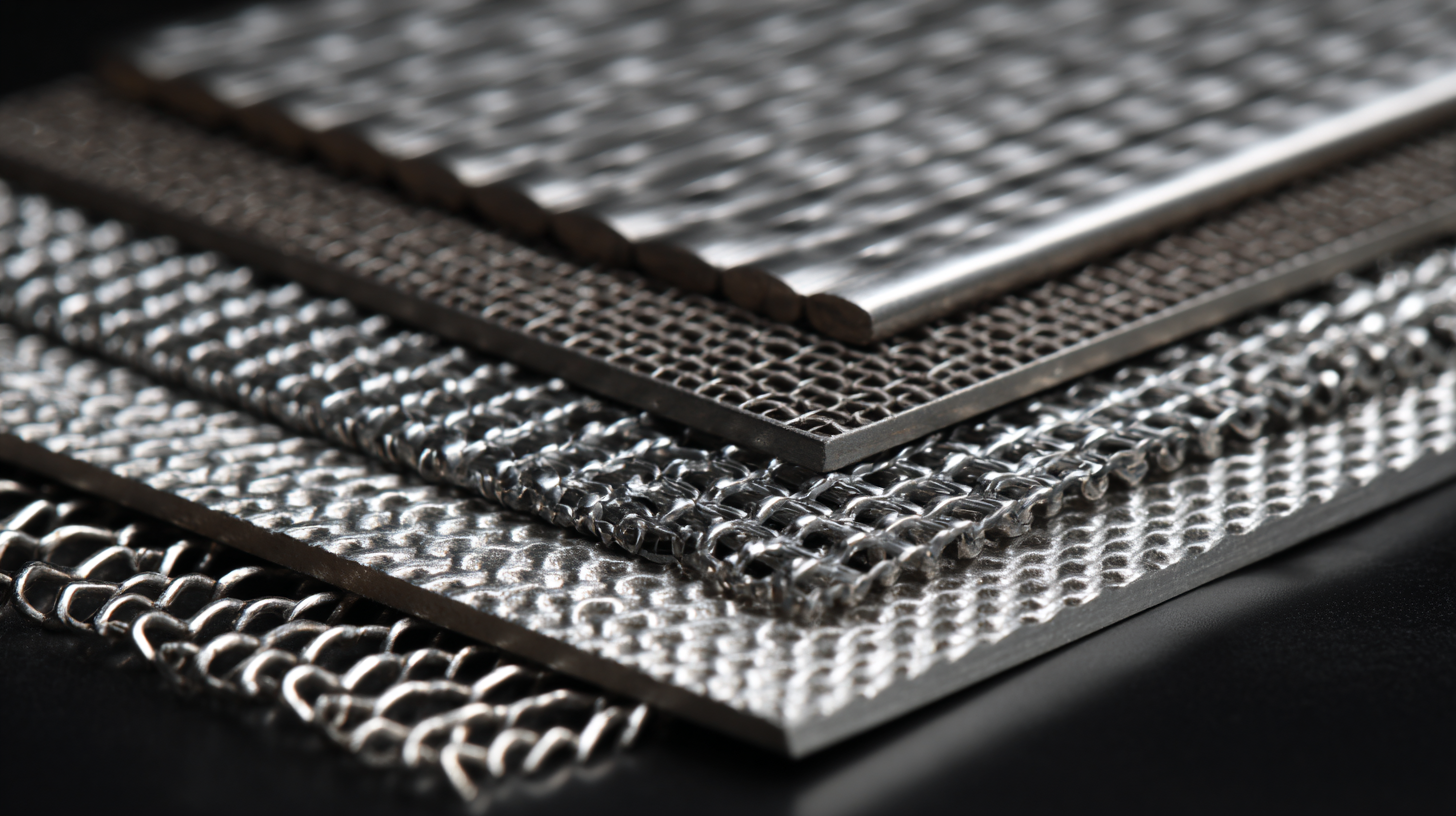

Exploring the Versatility of Stainless Steel Mesh in Modern Applications

As industries evolve and modern applications demand innovative solutions, the versatility of stainless steel mesh has emerged as a pivotal element across various sectors. According to a report by MarketsandMarkets, the global stainless steel market was valued at approximately $120 billion in 2020, with a steady growth trajectory projected due to the material's unmatched properties such as corrosion resistance and mechanical strength. Stainless steel mesh is increasingly utilized in industries ranging from architecture and construction, where it enhances aesthetic appeal while providing structural integrity, to food processing and pharmaceuticals, where hygiene and safety are paramount. The unique characteristics of stainless steel mesh allow it to serve diverse functions, including filtration, reinforcement, and protective barriers, making it indispensable in today's high-tech applications. This exploration delves into the myriad ways stainless steel mesh is revolutionizing industry standards and shaping the future of material use in modern applications.

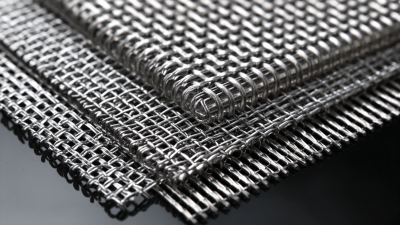

Understanding the Properties of Stainless Steel Mesh for Diverse Applications

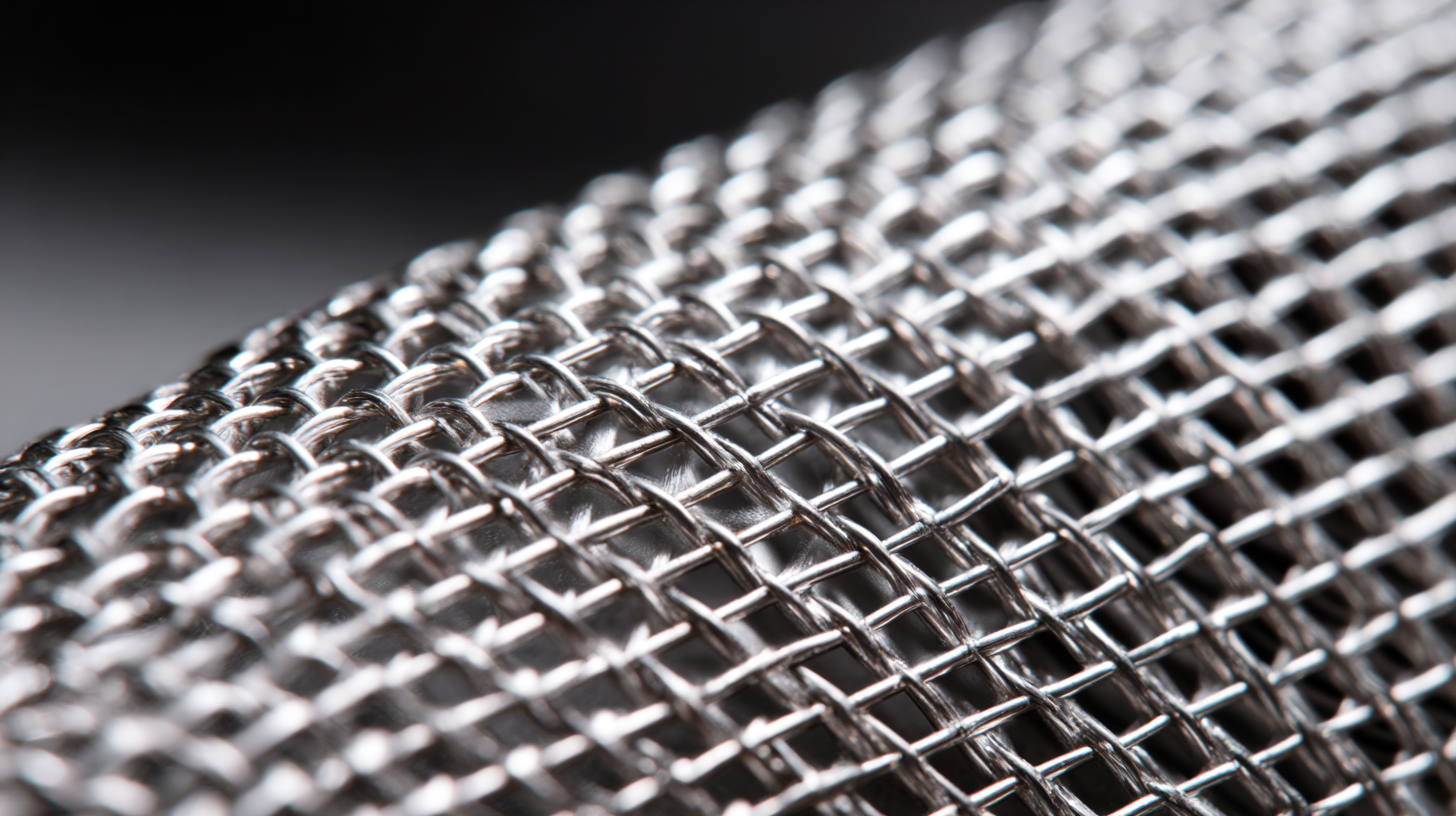

Stainless steel mesh exhibits remarkable versatility across various modern applications, primarily due to its unique properties, including strength, durability, and resistance to corrosion. In aerospace engineering, for instance, research into the mechanical properties of stainless steel wire mesh in hybrid composites illustrates its potential to enhance structural integrity while reducing weight. This makes it an ideal choice for components requiring high performance under demanding conditions.

Stainless steel mesh exhibits remarkable versatility across various modern applications, primarily due to its unique properties, including strength, durability, and resistance to corrosion. In aerospace engineering, for instance, research into the mechanical properties of stainless steel wire mesh in hybrid composites illustrates its potential to enhance structural integrity while reducing weight. This makes it an ideal choice for components requiring high performance under demanding conditions.

Moreover, the development of specialized mesh for oil-water separation showcases the adaptation of stainless steel mesh in environmental applications. By engineering specific surface characteristics, such as superwetting properties, these membranes effectively mitigate pollution in harsh conditions. This adaptability not only enhances functionality but also opens new avenues for addressing pressing environmental issues.

Tips: When considering stainless steel mesh for your projects, evaluate its specific properties such as mesh size and thickness, as these can dramatically influence performance. Additionally, stay updated on recent advancements in material science which could inform more efficient designs and applications, particularly in filtration and composite materials.

Key Industries Utilizing Stainless Steel Mesh: A Comprehensive Overview

Stainless steel mesh has emerged as a critical component across various industries, showcasing its versatility in applications ranging from filtration to architectural design.

According to a recent market research report published by Custom Market Insights, the Global Stainless Steel Scrap Market continues to thrive, indicating robust demand for stainless steel products. This durability and resistance to corrosion make stainless steel mesh a preferred choice in sectors like food processing, wastewater management, and construction.

The report highlights that the food and beverage industry significantly contributes to this demand, driven by stringent hygiene standards and the need for reliable filtration systems.

Moreover, the demand for innovative separation technologies has skyrocketed, especially in the oil and gas sector, where superwetting metal mesh membranes are gaining traction for their efficiency in oil/water separation.

This comprehensive exploration reflects a growing trend towards sustainable industrial practices. As industries recognize the advantages of stainless steel mesh, including its longevity and recyclability, the trend is expected to expand further, promoting a shift towards eco-friendly solutions while maintaining operational efficiency.

Step-by-Step Guide to Selecting the Right Stainless Steel Mesh for Your Project

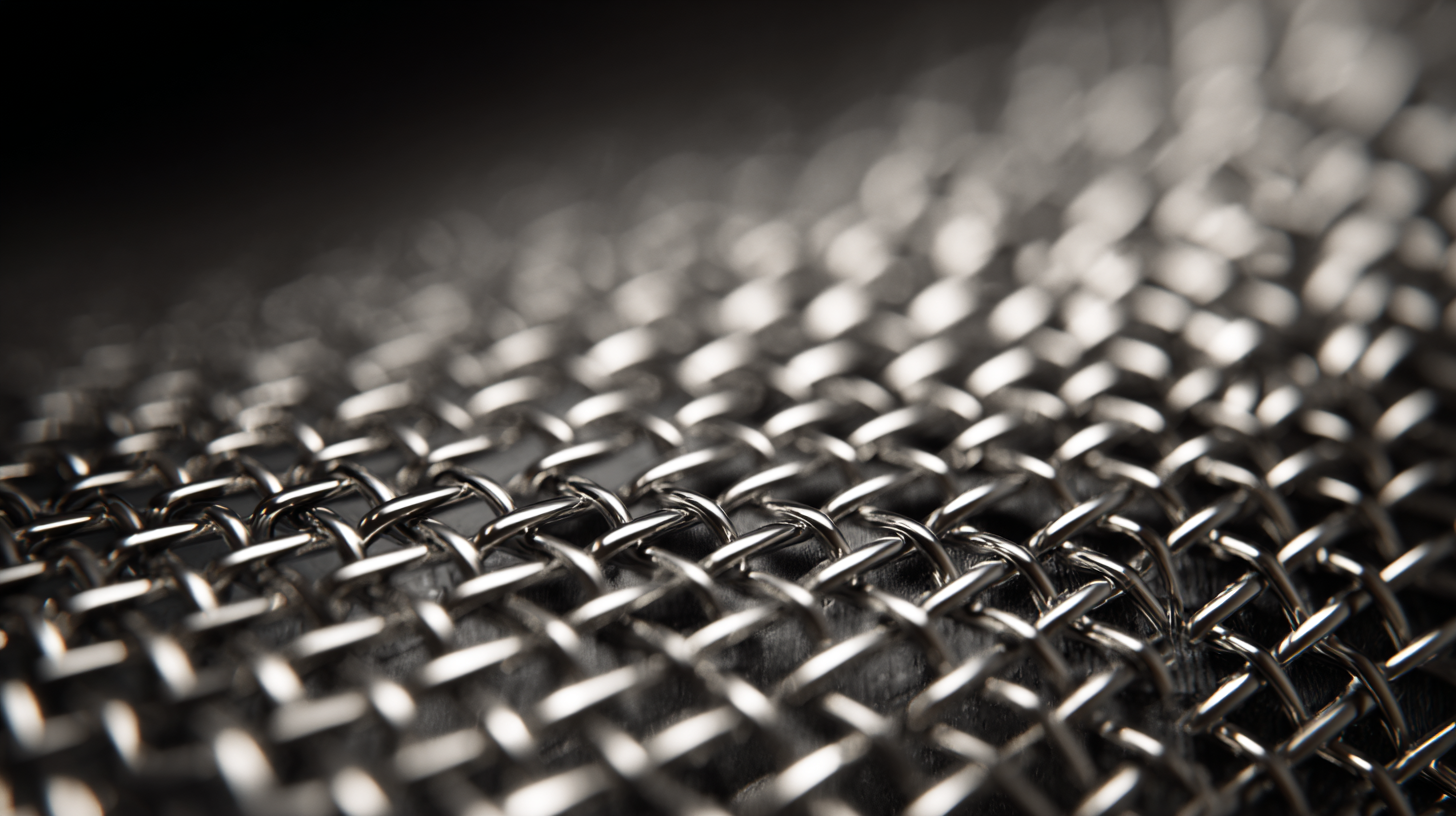

When selecting the right stainless steel mesh for your project, the first step is to determine the specific application and environment in which the mesh will be used. Consider factors such as exposure to chemicals, temperature, and mechanical stress. Different grades of stainless steel offer varying levels of corrosion resistance and strength, making it crucial to choose one that aligns with your project requirements. For instance, 304 stainless steel is suitable for general use, while 316 alloy provides enhanced protection in marine or highly corrosive settings.

Next, assess the mesh's specifications, including gauge, opening size, and wire diameter. These factors will affect the mesh's durability, filtration capabilities, and aesthetic qualities. A finer mesh may be necessary for filtration applications, while a more robust mesh might be ideal for structural support. Additionally, it’s essential to evaluate the mesh's density and pattern to achieve the desired balance between strength and airflow or visibility. By carefully considering these elements, you can ensure the stainless steel mesh you select will not only perform well but also enhance the overall success of your project.

Innovative Techniques for Fabricating and Installing Stainless Steel Mesh

Stainless steel mesh has become an essential component in various modern applications due to its durability, flexibility, and resistance to corrosion. In recent years, innovative techniques for fabricating and installing stainless steel mesh have emerged, enhancing its utility across different industries. For instance, advances in laser cutting technology allow for precision shaping of mesh products, resulting in custom designs that meet specific requirements. According to a report by Grand View Research, the global market for stainless steel mesh is expected to reach $3.12 billion by 2025, driven by the increasing demand for high-quality construction and architectural applications.

Installation methods have also evolved with the introduction of prefabricated mesh panels, which streamline the assembly process. These panels not only reduce labor costs but also minimize the time needed for on-site installation. Furthermore, innovations in bonding and fastening techniques—such as using specialized adhesives or innovative anchoring systems—ensure that stainless steel mesh is securely integrated into structures without compromising its integrity. A recent study published in the Journal of Construction and Building Materials indicates that using advanced installation techniques can improve longevity and performance, leading to a lifecycle cost reduction of up to 15%. The combination of these innovations is setting new standards for efficiency and customization in the application of stainless steel mesh.

Maintaining and Caring for Stainless Steel Mesh: Tips for Longevity and Performance

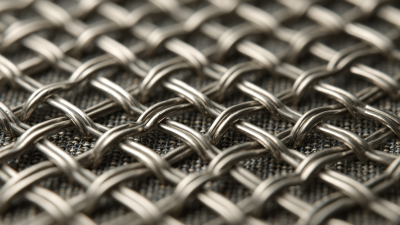

Maintaining stainless steel mesh is crucial for ensuring its longevity and optimal performance across various applications. According to a report by the International Stainless Steel Forum (ISSF), stainless steel has an impressive durability that can last for decades with proper upkeep. Regular cleaning is essential, as contaminants such as dust, grease, and chemicals can lead to corrosion if left unchecked. Utilizing a mild detergent and a soft brush or cloth for inspection and cleaning can prevent buildup and maintain the aesthetic appearance of the mesh.

Furthermore, monitoring the mesh under environmental stressors is pivotal. The World Steel Association highlights that stainless steel mesh is particularly resistant to corrosion in marine environments due to its chromium content, but even it requires periodic inspections for signs of wear. Protective coatings can enhance performance against harsh conditions, and applying these treatments can extend the life of the stainless steel mesh significantly. Implementing these maintenance strategies not only preserves the functionality of the material but also optimizes its contribution to various modern applications, including filtration systems, architecture, and industrial uses.

Exploring the Versatility of Stainless Steel Mesh in Modern Applications - Maintaining and Caring for Stainless Steel Mesh: Tips for Longevity and Performance

| Application | Mesh Type | Maintenance Tips | Longevity Factor |

|---|---|---|---|

| Filtration Systems | Woven Mesh | Regular cleaning to prevent clogging | High resistance to corrosion increases lifespan |

| Construction | Expanded Mesh | Inspect for physical damage and repaint if necessary | Durability under heavy loads extends usability |

| Aesthetic Applications | Perforated Sheets | Wipe with mild detergent to maintain appearance | Resistance to fading helps maintain visual appeal |

| Food Industry | Filter Mesh | Sanitize regularly to ensure hygiene | 304 grade increases resistance to stains and rust |

| Automotive | Screen Mesh | Check for structural integrity and replace if damaged | Long-lasting under various environments |

Related Posts

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

How to Choose the Right Wire and Cable for Your Electrical Projects

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

How to Choose the Perfect Fireplace Screen for Your Home Decor

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications