Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

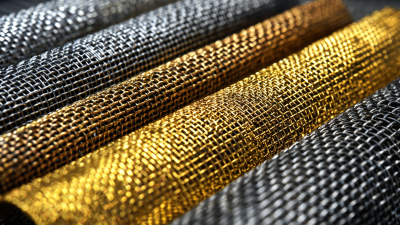

In recent years, the utilization of SS wire mesh has gained significant traction across various modern industries, owing to its remarkable versatility and robust properties. According to a report by MarketsandMarkets, the global wire mesh market is projected to reach $9.5 billion by 2025, with SS wire mesh constituting a substantial segment due to its corrosion resistance, durability, and aesthetic appeal. This adaptation is driven by its wide-ranging applications, from construction and manufacturing to food processing and filtration systems. The increasing demand for sustainable and high-performance materials underscores the importance of understanding SS wire mesh’s unique attributes and benefits. As industries continue to evolve, SS wire mesh stands out as a critical component that enhances structural integrity while offering innovative solutions to complex challenges, making it indispensable in the landscape of modern industrial applications.

How to Evaluate the Strength and Durability of SS Wire Mesh in Heavy-Duty Applications

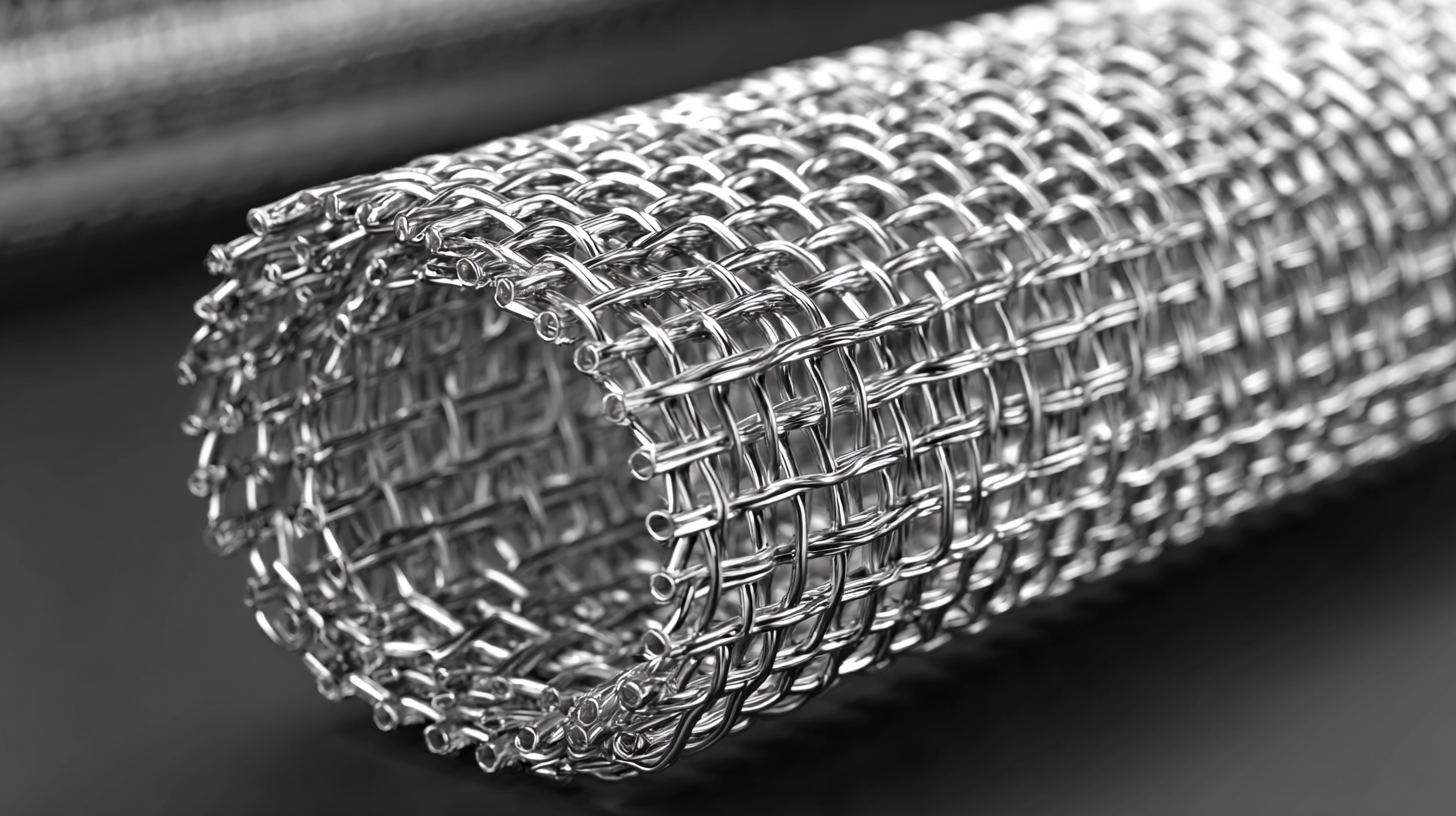

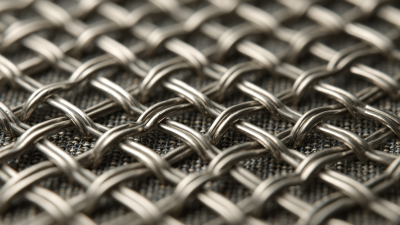

When evaluating the strength and durability of stainless steel (SS) wire mesh for heavy-duty applications, it is essential to consider its material properties and structural integration. SS wire mesh is renowned for its corrosion resistance, tensile strength, and ability to withstand harsh environmental conditions. Recent studies, such as those examining eco-friendly wire mesh configurations, reveal that integrating varying types of steel wire meshes can enhance sustainability while maintaining robust mechanical performance in reinforced concrete structures. For instance, lightweight aggregate concrete (LWAC) has shown improved mechanical properties when reinforced with specific SS mesh types.

In heavy-duty applications, the impact resistance of concrete structures can be significantly enhanced when using SS wire mesh in conjunction with innovative materials, like 5D fibers. These advancements are a response to the rising demand for sustainable construction methods driven by resource scarcity and environmental concerns. Reports indicate that using durable materials can extend the lifespan of concrete structures while also improving their resilience against dynamic loads.

**Tips:** When selecting SS wire mesh, always assess the mesh specifications, including wire gauge and opening size, to ensure compatibility with your application. Additionally, consider conducting comparative tests of different mesh types to determine the optimal configuration for your specific environmental and mechanical requirements. Regular maintenance checks of the mesh can also help in prolonging its life and ensuring structural integrity.

How to Choose the Right SS Wire Mesh for Your Specific Industry Needs

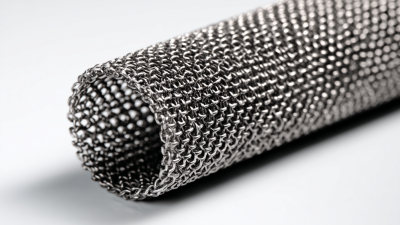

When selecting the right stainless steel (SS) wire mesh for your specific industry needs, it is essential to consider various factors, including mesh size, material grade, and application requirements. According to a report by Mordor Intelligence, the global stainless steel wire market is projected to reach USD 16.4 billion by 2025, indicating a growing demand across multiple sectors such as food processing, pharmaceuticals, and construction. Each application necessitates a different type of wire mesh, with the food industry typically favoring 304-grade stainless steel for its corrosion resistance and ability to withstand cleaning protocols.

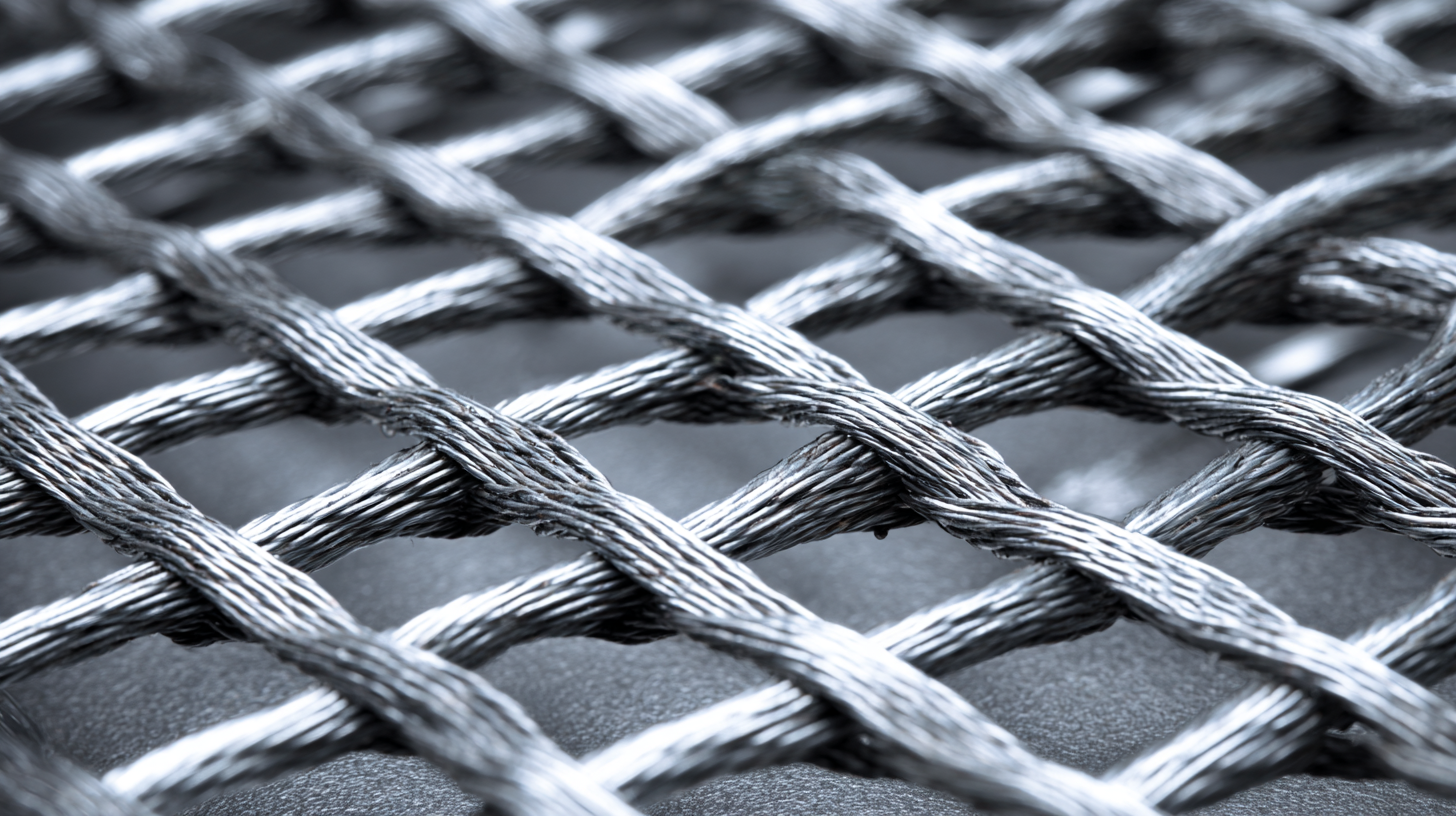

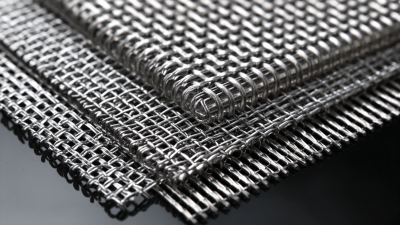

Moreover, understanding the specifications such as the wire diameter and opening size is crucial. For instance, a finer mesh may be required for applications like filtration in chemical processes, where a 325 mesh (over 60 microns) is commonly used, as noted in a recent Technical Associations report. In contrast, industries involved in heavy-duty tasks such as construction often utilize heavier gauge meshes to provide the strength and durability needed for structural support and safety applications. Hence, businesses must rigorously assess their operational demands to determine the optimal SS wire mesh type that aligns with their performance standards.

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

| Industry | Application | Benefits | Mesh Size |

|---|---|---|---|

| Manufacturing | Filtration | Durability and corrosion resistance | 0.5 mm |

| Construction | Reinforcement | Increased structural integrity | 1.5 mm |

| Food Processing | Safety Screens | Hygienic and easy to clean | 1.0 mm |

| Mining | Separation | High strength and wear resistance | 3.0 mm |

| Automotive | Grills and Shields | Aesthetic appeal and protection | 2.0 mm |

How to Maximize the Benefits of SS Wire Mesh in Filtration and Separation Processes

Stainless steel (SS) wire mesh has steadily gained recognition in various industries due to its exceptional properties and adaptability, particularly in filtration and separation processes. According to a market research report by MarketsandMarkets, the global wire mesh market is expected to reach USD 7.2 billion by 2025, driven by increasing industrial applications. The fine mesh construction of SS wire ensures superior filtration efficiency, making it an optimal choice for sectors ranging from pharmaceuticals to food and beverage processing, where precision is paramount.

To maximize the benefits of SS wire mesh, it is crucial to consider both the mesh size and the weave pattern. A study by Smithers Pira highlights that the proper selection of mesh can enhance throughput rates and retention performance by up to 30%. For instance, a tighter mesh allows for finer filtration, effectively capturing smaller particles, while specific weave designs can improve strength and resistance against corrosion. Thus, adopting the right specifications in SS wire mesh not only improves operational efficiency but also extends the lifespan of the filtration systems, fostering reliability in output quality across modern industries.

How to Implement SS Wire Mesh Solutions for Enhanced Safety in Construction Sites

SS wire mesh is an increasingly vital component in the construction industry, primarily due to its strength and durability. Implementing SS wire mesh solutions at construction sites not only enhances structural integrity but also significantly improves safety protocols. The versatility of SS wire mesh makes it suitable for a variety of applications, including safety fencing, reinforcement in concrete, and as a barrier during construction activities. By utilizing high-quality SS wire mesh, contractors can ensure that their projects meet both safety and performance standards.

**Tip:** When selecting SS wire mesh, consider the specific requirements of your project, such as load-bearing capacity and environmental exposure. This will help ensure compliance with safety regulations and optimize the structure's durability.

Moreover, using SS wire mesh aids in reducing the risk of accidents on-site. It provides a protective barrier that can prevent debris from falling and restrict unauthorized access, thereby protecting workers and mitigating liability. As industries shift towards more sustainable practices, the use of resistant materials like SS wire mesh aligns with eco-friendly construction trends.

**Tip:** Always ensure that the installation of SS wire mesh adheres to local building codes and regulations for safety compliance. Regular inspections can further enhance safety measures and prolong the lifespan of your construction projects.

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

This chart illustrates the versatility of stainless steel (SS) wire mesh across various modern industries, highlighting the percentage of usage in each sector. As demonstrated, construction leads in application, followed by agriculture and other key sectors, showcasing the material's diverse benefits in enhancing safety and functionality.

How to Maintain SS Wire Mesh for Longevity and Optimal Performance in Various Environments

Maintaining stainless steel wire mesh (SS wire mesh)

(SS wire mesh) is essential for ensuring its longevity and optimal performance across various environments.

Regular cleaning is one of the fundamental practices;

it prevents the buildup of contaminants that can lead to corrosion or reduced functionality.

For industries exposed to corrosive materials, using mild detergents and non-abrasive scrubbers can effectively remove deposits without damaging the mesh.

Additionally, implementing a routine inspection schedule can help identify any signs of wear or degradation early on,

allowing for timely repairs or replacements.

Furthermore, the storage conditions of SS wire mesh significantly influence its lifespan.

It is crucial to keep the mesh in a dry, well-ventilated area to minimize exposure to moisture, which can induce rust, even in stainless steel.

If the wire mesh is used in outdoor settings, applying a protective coating can enhance resistance to environmental elements,

thereby extending its usability. By adopting these maintenance strategies, industries can maximize the efficiency and durability of their SS wire mesh,

ensuring it meets the demands of their specific applications effectively.

Related Posts

-

How to Choose the Right Stainless Mesh for Your Specific Applications

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!