Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

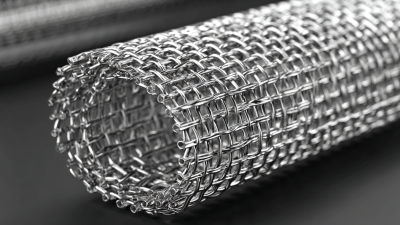

Steel wire mesh has become an indispensable component in modern construction, owing to its remarkable versatility and myriad applications. According to a recent report by Markets and Markets, the global steel wire mesh market is projected to reach USD 9.3 billion by 2025, growing at a CAGR of 6.7%. This surge is primarily driven by the increasing demand for robust construction materials that enhance structural integrity while reducing overall building costs. Steel wire mesh, known for its durability and strength, plays a pivotal role in various construction projects, from residential buildings to large-scale infrastructure developments.

The unique properties of steel wire mesh, including high tensile strength and resistance to corrosion, are vital in reinforcing concrete structures, ensuring they can withstand dynamic loads and environmental stresses. A study by Research and Markets highlights that the construction sector's emphasis on sustainable practices further elevates the significance of steel wire mesh, as it often optimizes material usage and decreases waste. With advancements in manufacturing technologies, the application of steel wire mesh continues to expand, incorporating innovations that improve performance and functionality, such as welded wire fabric and galvanized coatings. This article delves into the versatility and numerous applications of steel wire mesh, underscoring its essential role in shaping the future of construction.

The Role of Steel Wire Mesh in Structural Reinforcement for Enhanced Durability

Steel wire mesh plays a pivotal role in the structural reinforcement of construction projects, enhancing the overall durability and longevity of buildings. Its integration into concrete structures not only strengthens their integrity but also addresses critical issues such as punching shear failure, which is common at the connections between flat slabs and reinforced concrete columns. Recent studies highlight the effectiveness of using wire mesh combined with integrity bars and fibers to bolster the punching shear and post-punching behavior of flat slabs, offering a promising solution to mitigate structural vulnerabilities.

Steel wire mesh plays a pivotal role in the structural reinforcement of construction projects, enhancing the overall durability and longevity of buildings. Its integration into concrete structures not only strengthens their integrity but also addresses critical issues such as punching shear failure, which is common at the connections between flat slabs and reinforced concrete columns. Recent studies highlight the effectiveness of using wire mesh combined with integrity bars and fibers to bolster the punching shear and post-punching behavior of flat slabs, offering a promising solution to mitigate structural vulnerabilities.

Moreover, advanced materials are being developed to improve performance in challenging environments. For instance, research has demonstrated that enhanced Ni-NiO coatings significantly improve the corrosion protection of mild steel within alkaline concrete settings, which is crucial for maintaining the structural integrity of reinforced concrete over time. The increasing adoption of hybrid fibers and optimized mesh sizes in reinforcement composites further illustrates how innovations in material technology can lead to superior mechanical properties, emphasizing the adaptability of steel wire mesh in meeting modern construction challenges. As evidenced by growth reports, the market for brick reinforcement mesh is projected to surge substantially, indicating a robust demand for these versatile materials in the construction industry.

Exploring the Benefits of Steel Wire Mesh in Sustainable Building Practices

Steel wire mesh has emerged as a fundamental component in sustainable building practices due to its multitude of benefits. One of the primary advantages is its strength-to-weight ratio, which allows for the construction of durable yet lightweight structures. This characteristic aids in reducing the amount of material required, thereby lowering the overall environmental impact of construction projects. As steel wire mesh can be produced from recycled materials, it further contributes to resource conservation and aligns with green building standards.

In addition to its structural benefits, steel wire mesh enhances energy efficiency within buildings. When used in reinforced concrete, it improves thermal performance, minimizing energy loss and reducing heating and cooling costs over time. The open configuration of the mesh allows for optimal airflow, contributing to better indoor air quality. Furthermore, its versatility means that it can be utilized in various applications, from reinforcing foundations to serving as a formwork for sustainable building materials, making steel wire mesh a valuable asset in the quest for eco-friendly construction solutions.

Cost-Effectiveness of Steel Wire Mesh in Modern Construction Projects

Steel wire mesh has emerged as a vital component in modern construction, primarily due to its cost-effectiveness and versatility. By providing a robust framework for reinforcement in concrete structures, steel wire mesh significantly reduces the amount of materials required without compromising structural integrity. This not only leads to reduced material costs but also minimizes labor expenses, making it an attractive option for budget-conscious construction projects.

Moreover, the inherent properties of steel wire mesh contribute to durability and long-term performance, which can mitigate future repair costs. Its lightweight nature allows for easier handling and installation, further driving down labor costs and project timelines. Additionally, the ability to customize wire diameters and spacing meets a variety of engineering requirements, making steel wire mesh suitable for everything from residential foundations to large-scale commercial buildings. As a result, its adoption in construction continues to grow, highlighting the blend of economic efficiency and structural reliability.

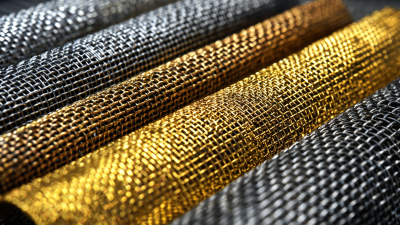

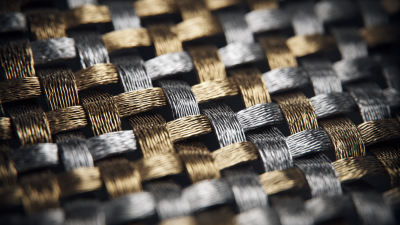

Innovative Applications of Steel Wire Mesh in Architectural Design and Aesthetics

Steel wire mesh has emerged as a pivotal element in modern architectural design, not only for its structural capabilities but also for its aesthetic appeal. According to a report by the International Journal of Architecture and Urban Development, the global market for steel wire mesh in construction is projected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is driven by innovative uses in both functional and decorative applications, positioning steel wire mesh as a versatile design solution.

Architects are increasingly incorporating steel wire mesh into facades, decorative partitions, and even as art installations. The versatility of this material allows for intricate designs that enhance light transmission while adding texture and depth to building exteriors. A study from the Architectural Institute of Japan highlights that buildings employing steel wire mesh not only meet structural demands but also provide unique visual experiences, often becoming focal points in urban landscapes. Such innovative applications demonstrate how steel wire mesh can bridge the gap between design and functionality, redefining modern architecture.

Understanding the Versatility of Steel Wire Mesh in Modern Construction

Comparative Analysis of Steel Wire Mesh vs. Traditional Reinforcement Methods in Construction

Steel wire mesh has emerged as a popular alternative to traditional reinforcement methods, such as rebar, in modern construction. One significant advantage of steel wire mesh is its ability to provide uniform strength and support across large surfaces, which reduces the chances of cracking and enhances the durability of concrete structures. Unlike rebar, which requires meticulous placement and a skilled labor force to ensure its effectiveness, steel wire mesh can be easily laid out and integrated into various construction elements, such as slabs and walls, streamlining the construction process.

Furthermore, when comparing the cost-effectiveness of steel wire mesh with traditional reinforcement methods, it becomes evident that wire mesh can offer significant savings. The manufacturing process of wire mesh is more efficient, resulting in lower material costs. Additionally, the lighter weight of steel wire mesh allows for easier handling and transportation, which can further reduce labor costs and improve overall project timelines. As construction practices evolve, the comparative benefits of steel wire mesh over traditional methods underscore its role in meeting the demands of modern building techniques, offering a versatile and efficient solution for a wide range of construction applications.

Related Posts

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

-

How to Choose the Right Wire and Cable for Your Electrical Projects