Top Uses of Stainless Steel Cable for Your Next Project

As industries continue to innovate and expand, the demand for durable and versatile materials has reached unprecedented levels. Among these, stainless steel cable has emerged as a leading choice for a variety of applications, thanks to its unique combination of strength, resilience, and corrosion resistance. According to a recent report by the International Cable and Wire Manufacturers Association, the global stainless steel cable market is projected to grow at a compound annual growth rate of 5.6% from 2022 to 2027. This growth is fueled by an increasing reliance on high-performance materials in construction, marine, and industrial sectors.

Industry expert Dr. Emily Richardson, a materials engineer at the Steel Institute, emphasizes the significance of stainless steel cable, stating, "The versatility of stainless steel cable makes it an essential component in modern construction and engineering projects; its ability to withstand environmental factors without compromising integrity is unparalleled." This insight reflects the critical role that stainless steel cable plays in ensuring safety and reliability across various industries, highlighting its numerous uses from rigging in maritime applications to architectural supports and safety barriers.

With its exceptional properties and range of applications, understanding the top uses of stainless steel cable becomes vital for professionals in multiple sectors. As we delve into the various applications of this remarkable material, it becomes evident that stainless steel cable is not just a solution, but a cornerstone of innovation and reliability in today's projects.

Key Characteristics that Make Stainless Steel Cable Ideal for Projects

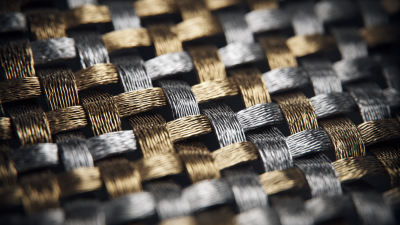

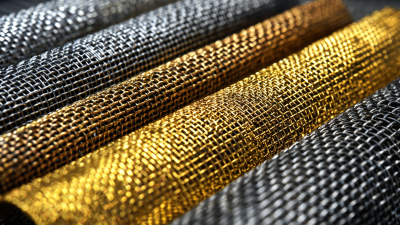

Stainless steel cable is increasingly favored in various industries thanks to its unique characteristics that enhance its utility across diverse projects. One of its key strengths lies in its corrosion resistance; according to a report by the International Stainless Steel Forum, stainless steel exhibits superior longevity in harsh environments, with a lifespan extending up to 50 years depending on the grade and application. This resilience makes it an ideal choice for outdoor installations, marine applications, and environments exposed to moisture or chemicals, where other materials would fail.

Another significant characteristic is its high tensile strength. Research shows that stainless steel cables can handle considerable loads, making them suitable for heavy lifting, suspension bridges, and architectural applications. The American Institute of Steel Construction highlights that stainless steel cables can withstand forces exceeding 200,000 psi, substantially more than traditional materials. Additionally, the flexibility and lightweight nature of these cables facilitate easier handling and installation, further streamlining the project execution process. As such, stainless steel cables should be a primary consideration for engineers and contractors looking to enhance durability and performance in their projects.

Common Applications of Stainless Steel Cable in Construction

Stainless steel cable has become an essential component in various construction projects due to its durability and resistance to corrosion. One of the most common applications is in structural support systems. Engineers and architects often utilize stainless steel cable for suspending beams, creating tensioned structures, and in cable-stayed bridges. Its high tensile strength allows for the effective transfer of load, making it an ideal choice for both aesthetic and functional support elements in modern architecture.

Another significant use of stainless steel cable is in safety and security applications. It is frequently employed in guardrails, safety barriers, and fall protection systems. The inherent strength of stainless steel, combined with its resistance to environmental factors, ensures that these installations remain secure and reliable over time. Additionally, stainless steel cables are used in rigging for scaffolding and various lifting mechanisms, offering flexibility and safety in complex construction environments. This versatility makes stainless steel cable an invaluable resource in ensuring the integrity and safety of construction sites.

Using Stainless Steel Cable for Safety and Security Solutions

Stainless steel cable is increasingly popular in the construction of safety and security solutions due to its durability and resistance to corrosion. According to a report by the Specialty Steel Industry of North America, stainless steel cables can withstand extreme weather conditions, which makes them ideal for outdoor applications such as fencing, marine hardware, and structural rigging. The cables provide an added layer of protection, ensuring that installations remain secure over time, even in challenging environments.

When planning your project, consider using stainless steel cables for safety railings, which provide secure barriers while maintaining aesthetic appeal. A study from the American Society of Civil Engineers found that the use of stainless steel materials in construction can lead to a 20% increase in longevity compared to traditional cables. This longer lifespan reduces the need for frequent replacements, ultimately saving costs in maintenance and enhancing safety in public spaces or commercial buildings.

Tips: When choosing stainless steel cables, ensure that you select the appropriate gauge and type for your specific application. Additionally, consider incorporating protective coatings to further enhance the cable's resistance to environmental factors. Regular inspections of your stainless steel cable installations can help maintain safety standards and prevent potential hazards.

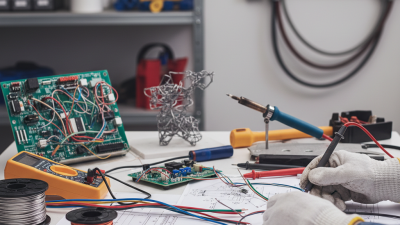

Innovative Uses of Stainless Steel Cable in Artistic Installations

Stainless steel cable has increasingly become a favored medium for artists seeking to integrate strength and elegance into their work. Its corrosion resistance and durability make it a prime choice for outdoor installations, where various weather conditions can be a significant factor. Artists can manipulate stainless steel cable into intricate designs, using it to create tension structures that balance between rigidity and fluidity. This versatility enables the formation of eye-catching sculptures and installations that engage onlookers with their dynamic shapes and reflections of light.

One of the most innovative applications of stainless steel cable in artistic contexts is in kinetic sculptures. These pieces often rely on movement, whether induced by wind, viewers, or mechanical elements. The flexibility of stainless steel cable allows artists to develop complex mechanisms that can move gracefully, creating a captivating visual experience. Additionally, using stainless steel cable in light installations can lead to stunning effects, as the cables can be woven through LED lighting systems, enhancing the interplay of light and shadow. This not only elevates the aesthetic quality of the artwork but also adds an interactive dimension, inviting audience participation in experiencing the artwork from different angles.

Top Uses of Stainless Steel Cable for Your Next Project - Innovative Uses of Stainless Steel Cable in Artistic Installations

| Use Case | Description | Material Properties | Artistic Benefits |

|---|---|---|---|

| Suspended Art Displays | Elevating artwork in gallery spaces using cables for a modern aesthetic. | Corrosion-resistant, durable, and lightweight. | Creates a floating effect, enhancing visual appeal. |

| Outdoor Sculptures | Securing large sculptures in parks or urban areas. | Weather-resistant and strong. | Maintains integrity and visibility in various environments. |

| Railing Systems | Constructing safety railings for balconies or decks with aesthetic appeal. | High tensile strength and flexibility. | Provides safety without obstructing views. |

| Installation of Lighting Fixtures | Hanging lights in various artistic layouts using stainless steel cables. | Strong, can support significant weight. | Allows for creative and functional lighting designs. |

| Interactive Installations | Creating engaging art pieces that invite audience participation with movable elements. | Resilient and easy to manipulate. | Encourages viewer interaction and engagement. |

Maintenance Tips for Maximizing the Life of Stainless Steel Cable

When it comes to using stainless steel cable in various projects, understanding proper maintenance can significantly extend its lifespan. According to a report from the Stainless Steel Research Institute, regular upkeep can enhance the durability of stainless steel by as much as 50%, making it a worthwhile investment. Environmental factors such as saltwater exposure or industrial pollutants can lead to corrosion, which is the primary enemy of stainless steel cables. Thus, adopting a proactive approach to maintenance is essential for maximizing performance.

To keep your stainless steel cable in top condition, ensure it is cleaned regularly to remove dirt and contaminants. Utilizing a mild detergent and soft brush can effectively prevent buildup that encourages corrosion. Additionally, consider the installation environment; where possible, avoid direct exposure to harsh chemicals or environments prone to moisture accumulation. Another crucial tip is to inspect the cables periodically for any signs of wear or deterioration. Addressing issues early can prevent more significant problems down the line, maintaining the integrity of your installation.

Lastly, storing stainless steel cables correctly is vital. Keeping cables in a dry, controlled environment can help prevent corrosion that can occur when cables are stored in damp places. The Stainless Steel Association recommends using protective coatings or wraps when cables are not in use for extended periods. Adopting these practices not only enhances the longevity of your stainless steel cables but also ensures their reliability in critical applications.

Top Uses of Stainless Steel Cable

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

-

What is Cable Mesh and How It Revolutionizes Modern Construction

-

How to Choose the Right Wire Products for Your Project Needs

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

How to Choose the Right Metal Mesh for Your Industrial Applications