The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

In the ever-evolving landscape of manufacturing, the selection of appropriate wire mesh products is crucial for ensuring optimal performance and safety across various applications. According to a report by Grand View Research, the global wire mesh market was valued at approximately $6.9 billion in 2020, with expectations to grow at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2028. This growth highlights the increasing demand for these versatile materials in construction, filtration, and other industrial sectors. Understanding the different types, materials, and applications of wire mesh products is essential for businesses looking to enhance productivity and efficiency. Selecting the right wire mesh can prevent costly errors and ensure that projects meet regulatory and safety standards. As industries continue to rely more heavily on these products, making informed choices based on comprehensive knowledge of wire mesh options becomes imperative for success.

Understanding the Different Types of Wire Mesh Products Available

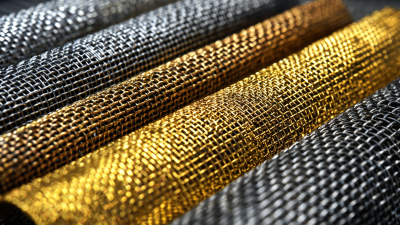

When it comes to selecting wire mesh products, understanding the various types available is crucial. Wire mesh can be categorized based on material, weaves, and applications, each suited to specific needs. For example, stainless steel wire mesh is renowned for its corrosion resistance and is ideal for environments exposed to moisture and chemicals. According to a recent industry report by MarketsandMarkets, the global market for wire mesh is expected to reach approximately $8.3 billion by 2026, reflecting an increasing demand across construction, agriculture, and manufacturing sectors.

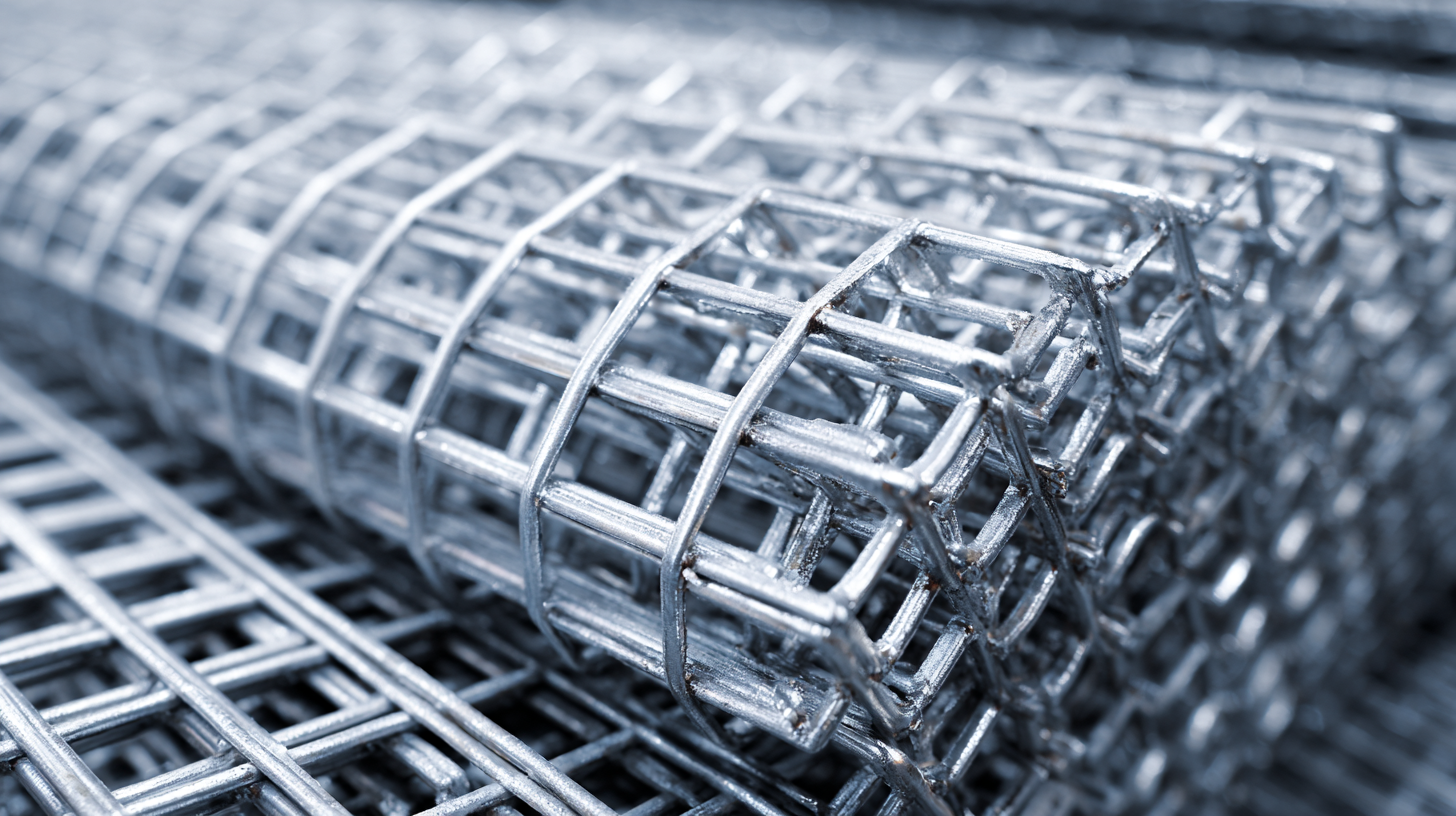

Another essential type is welded wire mesh, which offers enhanced strength and durability, making it suitable for reinforced concrete projects. Research indicates that welded wire mesh can provide structural integrity while reducing labor costs during construction. For particular applications, such as security and safety, expanded metal mesh is commonly used, offering visibility while maintaining strength. Whether for industrial, commercial, or residential use, understanding these different types of wire mesh products ensures you make an informed decision tailored to your specific requirements.

Key Factors to Consider When Choosing Wire Mesh for Your Project

When choosing wire mesh products for your project, it's crucial to consider several key factors to ensure that they meet your specific requirements. Firstly, the type of material plays a significant role in the performance and durability of the wire mesh. Common materials include aluminum, steel, and fiberglass-reinforced plastic (FRP). Each material has its unique properties, such as corrosion resistance and weight, which can affect the overall functionality of the wire mesh in different environmental conditions.

When choosing wire mesh products for your project, it's crucial to consider several key factors to ensure that they meet your specific requirements. Firstly, the type of material plays a significant role in the performance and durability of the wire mesh. Common materials include aluminum, steel, and fiberglass-reinforced plastic (FRP). Each material has its unique properties, such as corrosion resistance and weight, which can affect the overall functionality of the wire mesh in different environmental conditions.

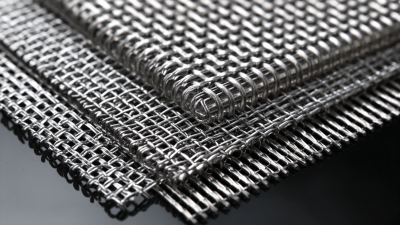

Next, the design and type of wire mesh should align with your project's intended use. For instance, if you need reinforcement, ladder-style mesh might be appropriate, while perforated panels may be better suited for applications where airflow or visibility is essential. Furthermore, understanding the specific requirements of your project, including load-bearing capacity and aesthetic preferences, can help guide your selection process. Engaging with manufacturers can provide additional insights into product specifications and suitable applications, ensuring that you make an informed choice that meets your project's demands.

How to Evaluate the Durability and Strength of Wire Mesh Materials

When selecting wire mesh products, evaluating the durability and strength of the materials is paramount. Wire mesh is commonly utilized in various industries, from construction to food processing, and its performance directly impacts safety and functionality. According to a report by the American Welding Society, the tensile strength of wire mesh can vary significantly based on the type of metal used; for instance, stainless steel mesh boasts tensile strengths upwards of 200,000 psi, making it a robust choice for demanding applications.

**Tips:** When assessing wire mesh durability, consider the environmental conditions it will face. Corrosive environments, for example, may require galvanized or stainless steel options to ensure longevity. Additionally, review industry standards such as ASTM A313 for stainless steel wire, which outlines critical mechanical properties to ensure quality and performance.

Conducting stress tests can further validate the effectiveness of your chosen wire mesh. The National Association of Architectural Metal Manufacturers emphasizes that regular testing procedures can predict the lifespan and performance under load conditions. For projects that demand high durability, opt for wire mesh with a higher gauge, which typically offers increased resistance to deformation and fatigue.

The Ultimate Guide to Choosing Wire Mesh Products

Assessing the Cost-Effectiveness of Wire Mesh Options

When evaluating the cost-effectiveness of wire mesh options, it's essential to consider both material and application-specific factors. According to a report by the Freedonia Group, demand for wire mesh products is projected to reach over $5.5 billion by 2025, demonstrating a significant growth driven by industries such as construction, agriculture, and manufacturing. These sectors have recognized that, while upfront costs may vary between different types of wire mesh, the long-term durability and maintenance savings can greatly enhance overall value.

For instance, stainless steel wire mesh, although typically more expensive initially than its galvanized counterparts, offers superior corrosion resistance and longevity. A study published in the Journal of Materials Science found that stainless steel wire mesh can last up to 50% longer than galvanized mesh in harsh environments. This longevity translates to reduced replacement costs and lower labor expenses over time, making it a smart investment for projects with high-performance demands. Thus, assessing the cost-effectiveness of wire mesh requires a comprehensive analysis of both short-term costs and long-term benefits tailored to your specific needs.

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs - Assessing the Cost-Effectiveness of Wire Mesh Options

| Wire Mesh Type | Material | Mesh Size (inches) | Cost per Square Foot | Durability Rating (1-10) | Common Applications |

|---|---|---|---|---|---|

| Welded Wire Mesh | Steel | 2 x 2 | $3.50 | 8 | Fencing, Reinforcement |

| Expanded Metal Mesh | Aluminum | 1/4 x 1/4 | $6.00 | 7 | Walkways, Guards |

| Chain Link Mesh | Galvanized Steel | 2 x 2 | $2.00 | 6 | Perimeter Fencing |

| Stainless Steel Wire Mesh | Stainless Steel | 1/8 x 1/8 | $10.00 | 9 | Food Processing, Chemical Industry |

| Fiberglass Mesh | Fiberglass | 1/4 x 1/4 | $4.00 | 5 | Construction, Insulation |

Essential Maintenance Tips for Longevity of Wire Mesh Products

To ensure the longevity of wire mesh products, proper maintenance is essential. Regular cleaning is a critical first step. Dust and debris can accumulate on wire mesh surfaces, leading to corrosion if left unaddressed. Use a soft brush or a pressure washer on lower settings to gently remove dirt without damaging the mesh. For tougher stains, a mixture of mild detergent and water can effectively clean the surface without introducing harsh chemicals that may compromise the material.

In addition to cleaning, it's important to inspect the wire mesh regularly. Look for signs of wear, such as rust, bent wires, or loose connections. Addressing these issues promptly can prevent further damage and extend the lifespan of the product. If repairs are needed, consider using appropriate repair kits or seeking professional assistance, particularly for larger installations. By following these essential maintenance tips, users can ensure their wire mesh products remain durable and effective for years to come.

Related Posts

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Metal Screen for Your Project

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Perfect Fireplace Screen for Your Home Decor

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency