Top Wire Mesh Products for 2026 What You Need to Know?

As we look ahead to 2026, the demand for wire mesh products is set to rise significantly. Businesses across various industries will increasingly rely on these versatile materials. Wire mesh products offer unique benefits, making them essential for construction, agriculture, and even filtration systems.

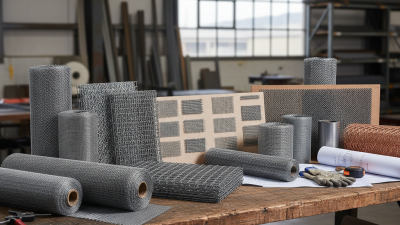

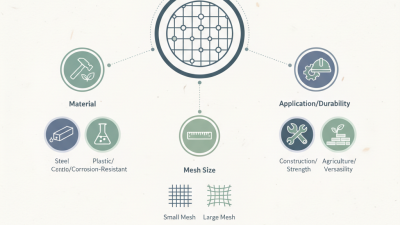

The variety of available wire mesh products will capture the attention of numerous sectors. Options range from welded and woven wire mesh to expanded metal. Each type serves different purposes, showcasing their adaptability. Market trends suggest a shift towards more sustainable materials as well. Companies may consider the environmental impact of their choices, blending functionality with eco-friendliness. However, a challenge remains: balancing cost and quality.

This evolving landscape urges manufacturers and consumers to reflect on their needs. Selecting the right wire mesh products can be complex. It requires careful consideration of specifications and potential applications. With innovation comes uncertainty, and making the right choices may not always be clear. As 2026 approaches, staying informed will be crucial for all stakeholders.

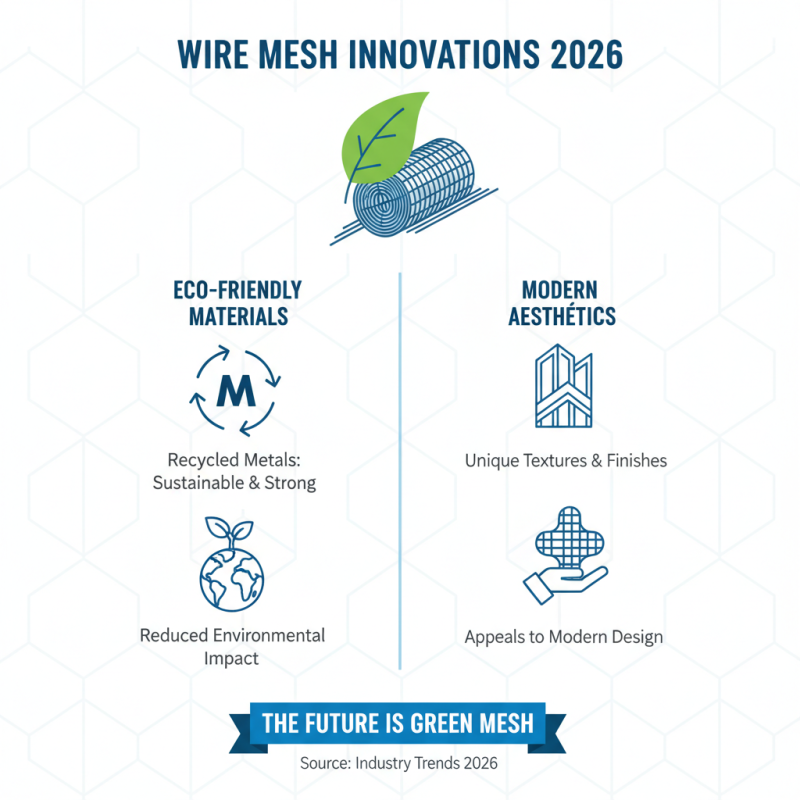

Emerging Trends in Wire Mesh Products for 2026

As we look ahead to 2026, wire mesh products are evolving in exciting ways. One noticeable trend is the increasing demand for eco-friendly materials. Manufacturers are exploring sustainable options, like recycled metals. This move is driven by a greater awareness of environmental impact. Sustainable products are not just good for the planet. They often have unique aesthetics that appeal to modern consumers.

Additionally, the versatility of wire mesh is being highlighted in various industries. From construction to agriculture, its applications are expanding. For instance, architects are incorporating decorative wire mesh in buildings to enhance visual appeal. This trend allows for creativity, but also raises questions about structural integrity. Designers must balance beauty with functionality, which is not always straightforward.

Another interesting aspect is the rise of smart technology integration within wire mesh products. Connecting wire mesh with sensors can improve security and monitoring. However, this requires careful planning to avoid privacy issues. Not all advancements are flawless. As new methods emerge, industry standards need to adapt. This is an ongoing challenge that invites reflection and collaboration among stakeholders.

Key Industries Utilizing Wire Mesh Technology

Wire mesh technology is becoming increasingly significant across various industries. Its versatility allows for a wide range of applications, from construction to food processing. The strength and durability of wire mesh make it ideal for use in reinforcing concrete structures. This aids in enhancing safety and stability, which is crucial in the construction sector.

In agriculture, wire mesh serves multiple purposes. Farmers utilize it for fencing and safeguarding crops against pests. It’s a practical choice for creating enclosures for livestock. However, not all wire mesh is created equal. The selection of the right type can be a challenge. It's essential to consider factors like corrosion resistance and the gauge of the wire. A common oversight is neglecting to anticipate long-term environmental effects.

The automotive industry also relies heavily on wire mesh. It plays a role in manufacturing filters and screens. These ensure that vehicles function efficiently and emissions remain within limits. Yet, producers may overlook the importance of quality checks. Subpar materials can lead to failures and costly recalls. Balancing cost and quality remains a constant struggle in this sector.

Top Wire Mesh Products for 2026 What You Need to Know? - Key Industries Utilizing Wire Mesh Technology

| Wire Mesh Type | Industry Application | Key Features | Projected Growth (%) |

|---|---|---|---|

| Stainless Steel Wire Mesh | Food Processing | Corrosion resistance, hygiene | 8.5 |

| Bronze Wire Mesh | Construction | Durability, aesthetic appeal | 5.2 |

| Welded Wire Mesh | Agriculture | Strength, easy installation | 7.0 |

| Barbed Wire Mesh | Security | High security, deterrent | 4.8 |

| Fiberglass Mesh | Construction | Lightweight, non-corrosive | 6.3 |

Innovations in Wire Mesh Materials and Manufacturing Processes

The wire mesh industry is rapidly evolving, driven by new materials and manufacturing methods. According to a recent market report, the global wire mesh market is projected to reach $8 billion by 2026, with a compound annual growth rate (CAGR) of 6.5%. This growth is partly due to advancements in materials like stainless steel and synthetic polymers, enhancing durability and corrosion resistance.

Innovations in manufacturing processes are also noteworthy. 3D printing and automation are revolutionizing how wire mesh is produced. These methods reduce waste and improve precision. Reports indicate that automated processes can increase production speed by up to 30%. However, not all manufacturers have adapted quickly to these changes. Some still rely on traditional methods, which can be less efficient and environmentally friendly.

As demand for custom solutions grows, manufacturers face challenges in meeting specifications. Producing wire mesh for diverse applications adds complexity. Industry experts emphasize that innovation is no longer optional; it's essential for survival. The ability to adapt and innovate defines the leaders in this space. The future of wire mesh relies on balancing efficiency with sustainability.

Top Wire Mesh Products for 2026

Safety Standards and Regulations Impacting Wire Mesh Products

When looking toward the future of wire mesh products in 2026, understanding safety standards is crucial. Industry reports indicate that stricter regulations are being introduced globally. These aim to enhance worker safety and product reliability. The Occupational Safety and Health Administration (OSHA) has set new guidelines that affect materials used in wire mesh, particularly in construction and industrial applications.

Adhering to these standards can significantly reduce workplace accidents. A report by the American National Standards Institute (ANSI) noted that companies aligning with updated safety certifications saw a 30% decrease in incidents. Compliance not only fosters a safer environment but also enhances a company’s reputation.

Tip: Regular training on safety regulations can empower employees. Keeping updated with local laws ensures compliance. Conduct periodic audits to assess safety equipment. Remember, safety is an ongoing commitment, not a one-time effort. The effectiveness of compliance hinges on continuous improvement.

While advancements in wire mesh technologies are impressive, the human element remains vital. Poor training or outdated knowledge can lead to risks. A survey revealed that 40% of incidents stemmed from lapses in understanding safety protocols. Investing in employee education is essential for mitigating this risk. Emphasizing safety standards will pave the way for better performance and fewer liabilities.

Sustainability Practices in Wire Mesh Production and Usage

Sustainability is increasingly important in wire mesh production. Many manufacturers are exploring eco-friendly materials. Recycled metal is often used as a base material. This reduces the demand for raw resources. However, not all producers prioritize sustainability equally. Some still rely on traditional methods that generate excess waste.

The usage of wire mesh also impacts the environment. Durable wire mesh products can last for years, reducing the need for replacements. This longevity helps minimize waste. On the other hand, improper disposal of old wire mesh can contribute to environmental pollution. Consumers need to be aware of proper recycling methods available in their communities.

While advancements are being made, challenges remain. The balance between cost-effectiveness and sustainable practices isn’t easy. Some companies may sacrifice sustainability for lower production costs. It’s crucial for consumers to push for more responsible practices. Increased awareness can drive change in the industry.

Related Posts

-

How to Choose the Best Wire Mesh Products for Your Project Needs

-

10 Essential Tips for Choosing the Right Metal Wire Mesh for Your Project

-

How to Choose the Right Wire Mesh for Your Project Needs

-

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

How to Choose the Best Wire Mesh for Your Home and Garden Projects