2025 Top 5 Fine Metal Mesh Products for Enhanced Performance and Durability

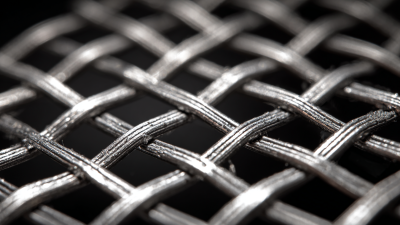

As we delve into the projected trends for 2025, the emphasis on performance and durability in industrial applications becomes increasingly paramount. Fine metal mesh has emerged as a critical component in various sectors, including aerospace, automotive, and electronics, where precision and reliability are non-negotiable. According to the latest industry reports, the global fine mesh market is anticipated to grow significantly, driven by advancements in manufacturing techniques and increasing demand for lightweight yet sturdy materials.

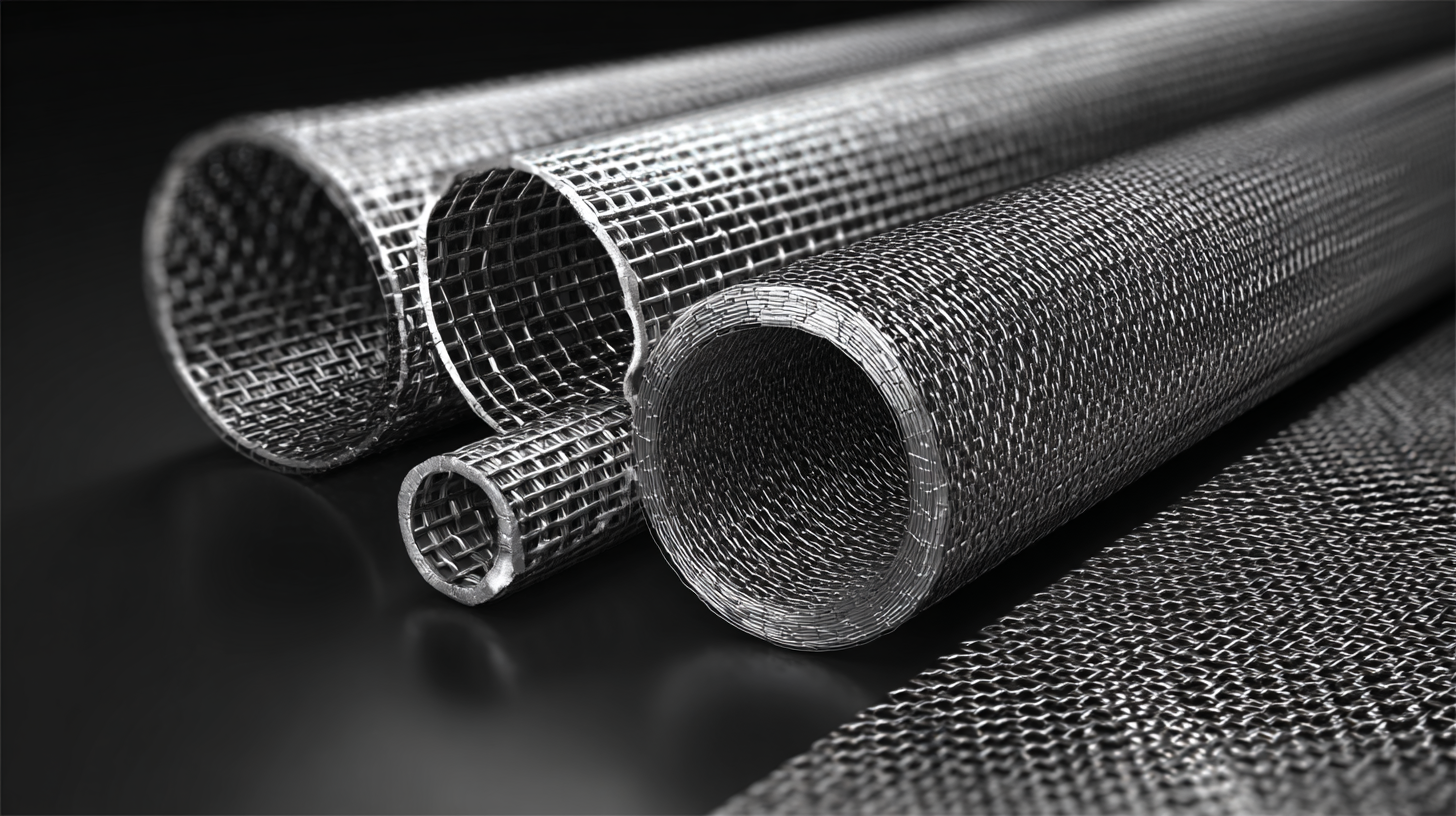

The unique properties of fine metal mesh, such as its high strength-to-weight ratio and excellent filtration capabilities, position it as an invaluable resource for enhancing product efficiency. A recent analysis estimated that the fine mesh applications in filtration and separation processes alone are expected to account for over 30% of market growth by 2025. This marks a notable shift as industries increasingly recognize the benefits of incorporating advanced fine metal mesh products into their operations.

In light of these advancements, we will explore the top five fine metal mesh products that are set to redefine performance standards in 2025. By focusing on innovative designs and robust materials, these products not only promise improved functionality but also longer life cycles, aligning with the industry's push for sustainability and efficiency.

Leading Innovations in Fine Metal Mesh Technologies for 2025

As we look toward 2025, the landscape of fine metal mesh technology is on the cusp of significant innovation. The advancements being made are not just about enhancing performance but also about increasing the durability of these products. Leaders in the industry are focusing on new materials and manufacturing techniques that allow for finer filtration without compromising strength. This promises to revolutionize various applications, from aerospace engineering to medical devices, where precision and reliability are paramount.

The insights shared at recent innovation forums point to a trend of collaboration among researchers, startups, and industry giants. This cross-disciplinary approach fosters the creation of tailored solutions that meet the evolving demands of various sectors. As the industry accelerates towards 2025, we can expect to see these innovative fine metal mesh products emerge as critical components in a range of technologies, pushing the boundaries of what’s possible in material science and engineering.

Key Performance Metrics: Assessing the Best Fine Metal Mesh Products

When evaluating fine metal mesh products for enhanced performance and durability, several key performance metrics should be considered. According to a report by Grand View Research, the fine metal mesh market is expected to reach $3.5 billion by 2025, exhibiting a CAGR of 7.4%. This growth highlights the increasing demand for products that not only meet stringent industrial standards but also offer longevity and resilience. Key performance metrics include tensile strength, corrosion resistance, and filtration efficiency, which are critical for applications in oil and gas, aerospace, and food processing.

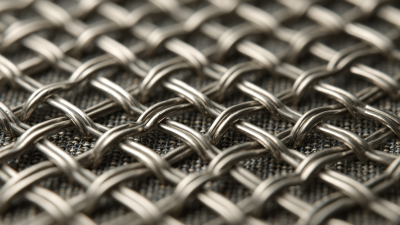

Tensile strength, for instance, is essential in ensuring that the mesh can withstand heavy loads without deformation. A study published in the Journal of Advanced Materials Research demonstrated that top-performing fine metal meshes exhibit tensile strengths exceeding 250 MPa, making them suitable for demanding environments. Corrosion resistance is another vital metric, particularly for mesh used in chemical processing; products treated with advanced coatings can provide more than 10 years of service life under harsh conditions. Filtration efficiency, measured by the ability to capture particles as small as 10 microns, can drastically influence operational performance, with leading products achieving over 98% efficiency in independent tests. These metrics not only determine the quality of fine metal mesh products but also their impact on operational excellence across various industries.

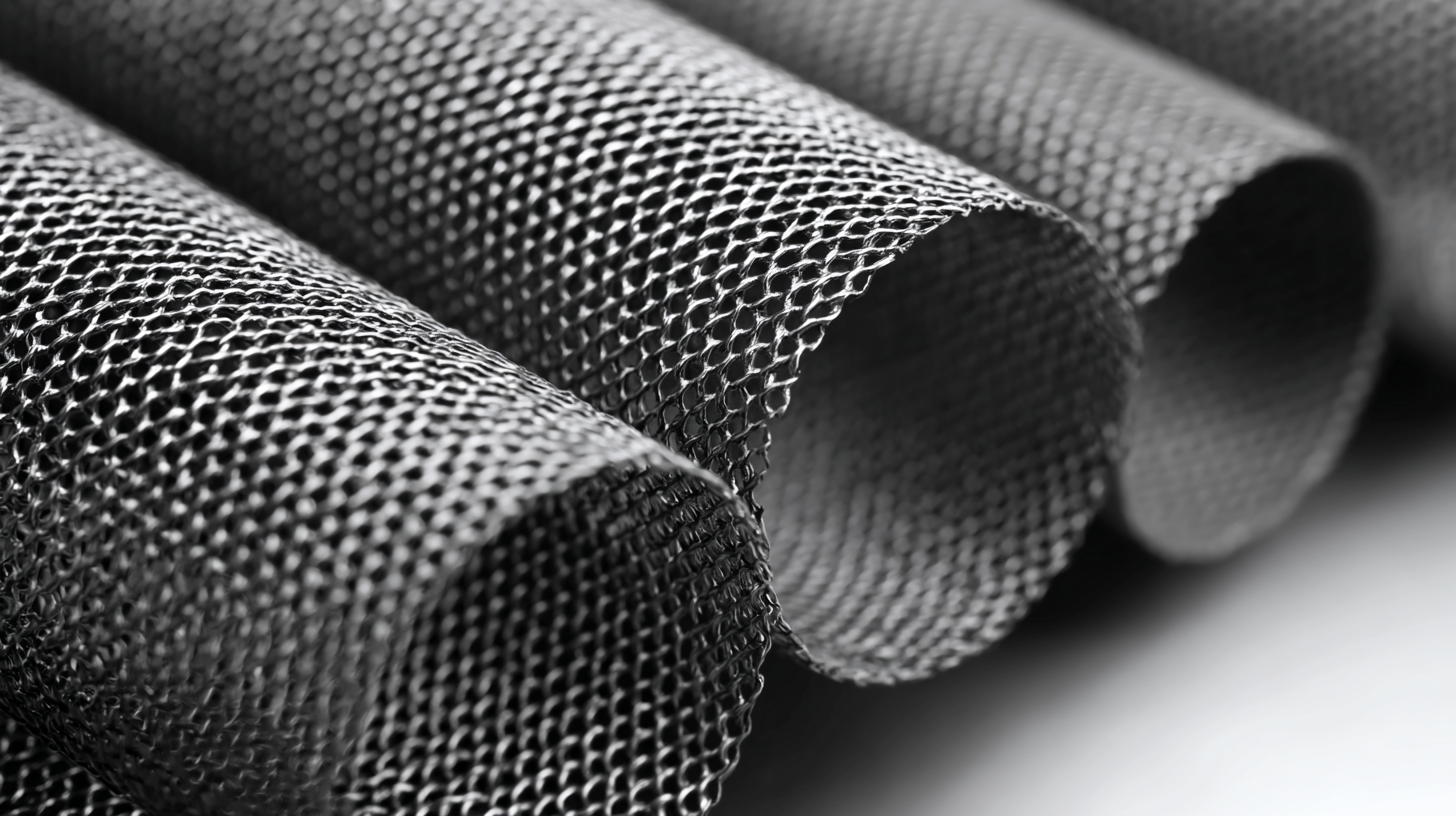

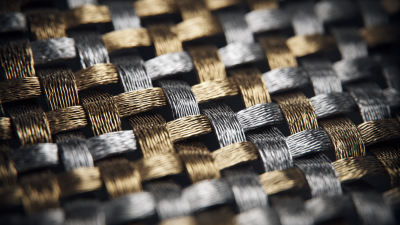

Durability Enhancements: Materials and Coatings in Fine Metal Mesh

Enhanced durability in fine metal mesh products is increasingly achieved through innovative materials and advanced coatings. Recent studies have highlighted bio-inspired approaches to mesh design, enabling improved performance in applications such as fog harvesting. For instance, as outlined in "Bio‐Inspired Fog Harvesting Meshes," the evolution of material properties combined with nature-inspired structures has led to significant advancements in water condensation efficiency. Such advancements can increase the longevity and water-harvesting capabilities of fine metal meshes, making them critical for sustainable applications.

Enhanced durability in fine metal mesh products is increasingly achieved through innovative materials and advanced coatings. Recent studies have highlighted bio-inspired approaches to mesh design, enabling improved performance in applications such as fog harvesting. For instance, as outlined in "Bio‐Inspired Fog Harvesting Meshes," the evolution of material properties combined with nature-inspired structures has led to significant advancements in water condensation efficiency. Such advancements can increase the longevity and water-harvesting capabilities of fine metal meshes, making them critical for sustainable applications.

Moreover, advancements in nanotechnology have also played a vital role in enhancing the durability of fine metal meshes. The application of new coating techniques can provide additional resilience against environmental stressors. A comprehensive review of scalable synthesis methods discusses how core-shell structures can optimize the electrochemical performance of lithium-ion batteries, effectively paralleling the need for durability in metal mesh applications. These innovations have demonstrated the potential to improve the lifecycle of these products, ensuring that they can withstand harsh operational conditions while maintaining high performance levels.

Applications of Fine Metal Mesh in Various Industries: A 2025 Perspective

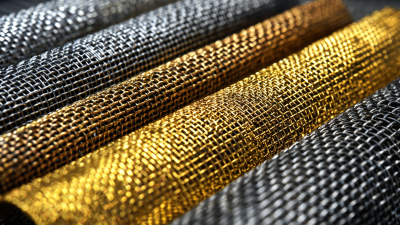

Fine metal mesh has found its way into various industries, showcasing versatility and providing significant enhancements in performance and durability. According to the Global Metal Mesh Market Report 2023, the market is projected to grow at a CAGR of 6.5% between 2023 and 2025, driven by its increasing applications in filtration, aerospace, and automotive sectors. In aerospace, fine metal mesh is crucial for lightweight components that can withstand high temperatures while providing optimal flow characteristics, which is essential for fuel efficiency and performance.

In the automotive industry, fine metal mesh is employed in powertrain systems for its ability to filter out contaminants while allowing for higher flow rates. A report by Future Market Insights highlights that the use of fine metal mesh in automotive applications could reduce emissions by up to 15% by promoting cleaner engine operations. Additionally, in the field of electronics, fine metal mesh is increasingly utilized in shielding applications to protect sensitive components from electromagnetic interference, thereby enhancing device reliability in an era of rapid technological advancements. As 2025 approaches, the role of fine metal mesh in these industries appears set to expand, contributing to more efficient and durable products.

Sustainability Trends in Manufacturing Fine Metal Mesh Products

The sustainability trends in manufacturing fine metal mesh products are gaining momentum in response to the growing demand for eco-friendly materials and processes. According to a recent study by the Global Metal Mesh Industry Report 2023, manufacturers are increasingly adopting sustainable practices, with over 60% of companies investing in recyclable materials. This shift not only reduces waste but also enhances the overall performance and durability of the final products. By integrating sustainability into their operations, companies are looking to meet consumer expectations while adhering to stricter environmental regulations.

To optimize the sustainability of fine metal mesh products, manufacturers are also focusing on energy-efficient production methods. Reports indicate that energy consumption in production could be reduced by up to 30% by utilizing advanced technologies such as automated systems and renewable energy sources. This not only decreases the carbon footprint but also leads to cost savings over time.

Tips: When considering fine metal mesh products, opt for manufacturers that prioritize sustainability in their supply chain. Look for certifications that indicate environmentally-friendly practices, and be mindful of the life cycle of the product, from production to disposal. Making informed choices can contribute to a more sustainable future in the metal industry.

Related Posts

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction