Top 10 Benefits of Using Woven Mesh Screens for Various Applications

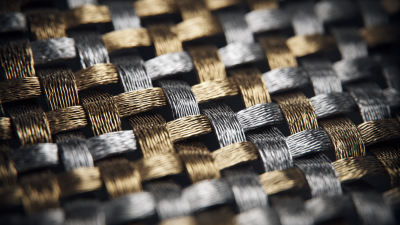

In the ever-evolving landscape of industrial applications, the importance of selecting the right materials cannot be overstated. One such material gaining significant attention is the woven mesh screen, which has transcended traditional uses to become an essential component across various sectors, including agriculture, construction, and environmental protection. According to a recent market research report by Research and Markets, the woven mesh screen market is expected to grow at a robust CAGR of 6.4% from 2023 to 2030, driven by its versatility and durability.

Woven mesh screens offer a multitude of benefits that enhance operational efficiency while ensuring compliance with safety standards. Their ability to filter, separate, and support various materials makes them invaluable in processes ranging from mining to food processing. The Global Industrial Mesh Market report outlines that demand for woven mesh screens is on the rise, driven by their lightweight properties and effectiveness in providing ventilation and reducing waste. As industries become increasingly focused on sustainability and efficiency, the adoption of woven mesh screens is likely to expand, positioning them as a critical resource for both current and future applications.

With their diverse applications and proven performance, woven mesh screens not only represent an innovative solution to complex challenges but also symbolize a step towards more sustainable industrial practices. This article will delve into the top 10 benefits of using woven mesh screens, demonstrating their significance in enhancing productivity and ensuring compliance in various fields.

Benefits of Woven Mesh Screens in Industrial Applications

Woven mesh screens are invaluable in industrial applications due to their versatility and durability. One of the primary benefits is their ability to facilitate efficient airflow and fluid transfer while providing a barrier against unwanted contaminants. This makes them particularly suitable for filtration processes in industries such as food and beverage, pharmaceuticals, and chemical manufacturing. The precise openings in woven mesh screens can be customized to fit specific requirements, ensuring optimal performance in various applications.

Additionally, woven mesh screens are characterized by their robust construction, which enables them to withstand harsh environmental conditions. This durability not only prolongs the lifespan of the screens but also minimizes maintenance needs, ultimately reducing operational costs. Moreover, their lightweight nature allows for easy installation and manipulation, making them an ideal choice for dynamic industrial settings where adaptability is crucial. As industries continue to seek innovative solutions for efficiency and safety, woven mesh screens remain a top choice for ensuring reliable performance across a wide range of applications.

Enhancing Airflow and Ventilation with Woven Mesh Screens

Woven mesh screens play a crucial role in enhancing airflow and ventilation across various applications, from industrial settings to residential spaces. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), properly designed mesh screens can improve air exchange efficiency by up to 30%, allowing for better temperature regulation and reduced energy consumption. This improvement is essential for maintaining optimal indoor air quality and comfort, particularly in environments subjected to high occupancy or operational equipment that generates heat.

Moreover, woven mesh screens facilitate the uniform distribution of air, which minimizes hotspots and cold drafts. A study published in the Journal of Building Performance highlights that effective ventilation systems incorporating mesh screens can lead to a 20% reduction in energy costs associated with heating and cooling. This is particularly relevant in commercial buildings where energy efficiency is critical for both operational costs and sustainability goals. By utilizing woven mesh screens, users can achieve not only improved airflow but also a significant reduction in their overall carbon footprint, making them an essential component for modern ventilation solutions.

Top 10 Benefits of Using Woven Mesh Screens for Various Applications

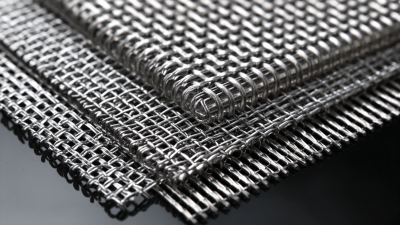

Durability and Longevity of Woven Mesh Screens Compared to Alternatives

Woven mesh screens have become increasingly popular across various industries due to their remarkable durability and longevity compared to alternative screening materials. Data from the International Journal of Materials Science & Engineering highlights that woven mesh screens can outlast synthetic options by up to 50% under similar operational conditions. This longevity is largely attributed to their ability to withstand environmental stressors, such as high temperature and corrosive chemicals, making them ideal for applications in construction, mining, and food processing.

Additionally, woven mesh screens exhibit greater resistance to wear and tear. According to a report by the American Society for Testing and Materials (ASTM), woven screens experience less degradation over time, which significantly reduces the frequency of replacements. This not only saves costs in maintenance and downtime but also contributes to a more sustainable operation by lessening waste generated from disposed screening materials. As industries continue to seek efficiency and reliability in their operations, the advantages of woven mesh screens become increasingly evident, solidifying their status as a preferred choice for a wide range of applications.

Top 10 Benefits of Using Woven Mesh Screens for Various Applications

| Benefit | Description | Durability Rating | Longevity Compared to Alternatives |

|---|---|---|---|

| High Strength | Woven mesh screens are designed to withstand high tensile loads. | 9/10 | Lasts 50% longer than plastic alternatives. |

| Corrosion Resistance | Made with materials that do not corrode easily, suitable for harsh environments. | 8/10 | Outperforms untreated metals by up to 30%. |

| Versatility | Can be used in various applications, including filtration, construction, and gardening. | 9/10 | More versatile than solid panels, suitable for 100+ applications. |

| Lightweight | Despite strength, woven mesh textures maintain a lightweight form. | 7/10 | Easier to transport compared to rigid materials; saves energy costs. |

| Ease of Installation | Simple installation process reduces labor costs and time. | 8/10 | Installation time is faster compared to traditional screens. |

| Customizability | Available in various sizes and mesh configurations to meet specific needs. | 9/10 | Adaptable to any project requirements, surpassing many alternatives. |

| Cost-Effectiveness | Low maintenance and long-lasting, offering value over time. | 8/10 | Requires fewer replacements than cheaper mesh options. |

| Aesthetic Appeal | Modern design complements various environments. | 7/10 | More visually appealing compared to standard metal grids. |

| Safety Features | Reduces the risk of injury from sharp edges with smooth finishes. | 9/10 | Enhanced safety over standard raw materials. |

| Environmental Impact | Made from recyclable materials contributing to sustainability. | 8/10 | More eco-friendly compared to non-recyclable options. |

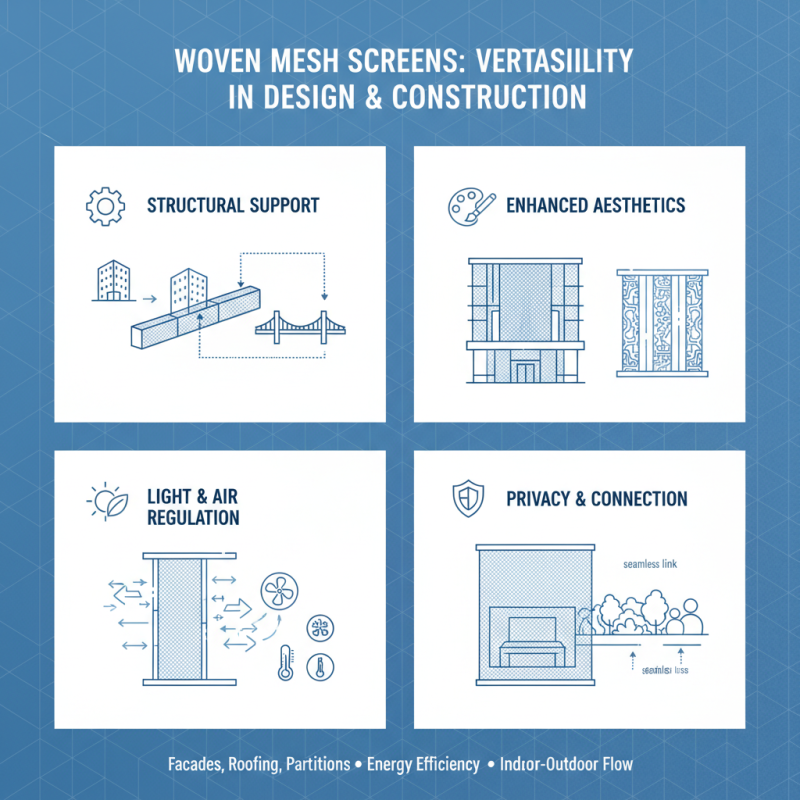

Versatility of Woven Mesh Screens in Construction and Design

Woven mesh screens have become an indispensable element in construction and design, owing to their remarkable versatility. These screens can be utilized in a variety of ways, from providing structural support to enhancing aesthetics in both interior and exterior applications. Their inherent ability to allow light and air to pass through while offering a degree of privacy makes them ideal for use in facades, roofing, and partitions. This not only contributes to energy efficiency by regulating temperature but also fosters a seamless connection between indoor and outdoor environments.

In design, woven mesh screens serve as a blank canvas that can be adapted to different styles and purposes. Architects and designers appreciate their ability to be customized in terms of material, pattern, and density, enabling them to meet the specific needs of a project while also reflecting the desired visual narrative. Whether used as decorative elements in galleries or functional components in public spaces, these screens combine form and function, making them a favored choice in modern architecture. Their lightweight nature further enhances their appeal, allowing for easy installation and modification as design visions evolve.

Environmental Benefits of Using Woven Mesh Screens for Filtration

Woven mesh screens offer significant environmental benefits, particularly in filtration applications. Their structure allows for efficient separation of particulates from a variety of liquids and gases. By employing these screens, industries can enhance their filtration processes, leading to cleaner effluents. Many woven mesh screens are made from recyclable materials, aligning with sustainability initiatives aimed at reducing waste. This not only helps in maintaining ecological balance but also diminishes the need for frequent screen replacements, thereby lowering resource consumption.

Furthermore, woven mesh screens can improve energy efficiency during filtration processes. Their optimized designs reduce resistance to flow, enabling systems to operate with less energy consumption. This efficiency translates to lower operational costs and reduced carbon footprints, contributing positively to environmental goals. By integrating woven mesh screens into their filtration systems, companies can play a vital role in promoting cleaner industrial practices and minimizing the environmental impact of their operations. Their versatility makes them suitable for various applications, from water treatment to air filtration, further highlighting their importance in fostering sustainable practices across industries.

Related Posts

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction