Top Tips for Choosing the Right Fine Metal Mesh for Your Project

When embarking on a project that requires a dependable and high-quality fine metal mesh, the variety of options available can be overwhelming. Understanding the specific requirements of your application is crucial for making an informed choice. According to the "Global Fine Metal Mesh Market Report 2022," the demand for fine metal mesh products is projected to grow by 6% annually, driven by their increasing applications in aerospace, automotive, and filtration industries. This growth underscores the importance of selecting the right type of mesh to meet both performance and regulatory standards.

Industry expert Dr. Jane Smith, a renowned analyst in the fine metal mesh domain, emphasizes, "Choosing the correct fine metal mesh not only enhances the efficiency of your project but can also significantly reduce operational costs." This highlights the critical nature of understanding mesh specifications, such as weave patterns, gauge sizes, and material compositions, which directly impacts the functionality and longevity of the products in diverse applications. With proper knowledge and guidance, professionals can navigate the complex landscape of fine metal mesh to ensure optimal outcomes for their projects, ultimately leading to better results and successful implementations.

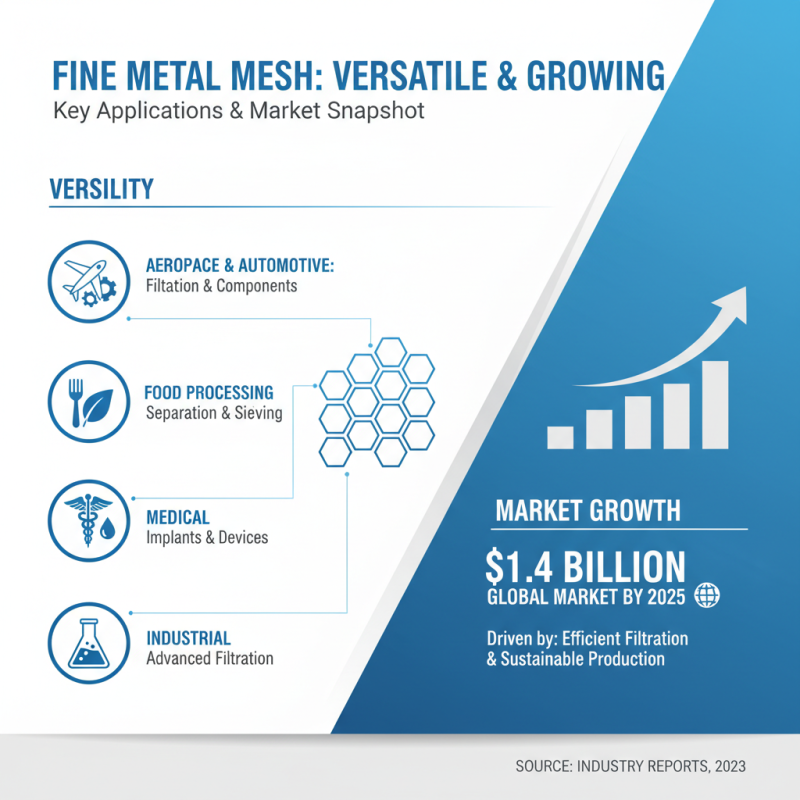

Understanding Fine Metal Mesh and Its Applications

Fine metal mesh is an incredibly versatile material, used across various industries due to its unique properties. Comprising a network of finely woven wires, fine metal mesh offers excellent filtration and separation capabilities, making it a crucial component in sectors such as aerospace, automotive, food processing, and medical applications. According to industry reports, the global market for metal mesh products is expected to grow significantly, reaching approximately $1.4 billion by 2025, driven by increased demand for efficient filtration technologies and sustainable production methods.

In practical applications, fine metal mesh is used for filtration systems to separate solids from liquids, ensuring high purity levels and efficiency. For instance, in the pharmaceutical industry, fine metal mesh can filter out contaminants in drug manufacturing processes, adhering to stringent regulatory standards. Additionally, its structural integrity and resistance to heat and chemicals make it ideal for use in high-stress environments. A study published in the Journal of Industrial Materials indicates that fine metal mesh can retain up to 99.9% of particulates, highlighting its effectiveness in applications requiring precision and reliability. As industries continue to prioritize efficiency and safety, the role of fine metal mesh will undoubtedly expand, further showcasing its significance in modern manufacturing and production processes.

Key Factors to Consider When Selecting Fine Metal Mesh

When selecting fine metal mesh for your project, several key factors should be taken into consideration to ensure that you choose the most suitable option for your needs. First and foremost, the mesh's material composition is crucial. Different metals, such as stainless steel, aluminum, or bronze, offer varying levels of strength, corrosion resistance, and conductivity. Consider the operating environment of your project; for instance, if it involves exposure to moisture or chemicals, stainless steel may be your best bet due to its superior corrosion resistance.

Another essential factor is the mesh density and opening size. The required filtration level or airflow will dictate the size of the openings and the density of the mesh. A finer mesh can provide better filtration but may restrict airflow, while a coarser mesh allows for greater airflow but might compromise filtration. It’s important to balance these requirements based on the specific application, whether for decorative purposes, functional guards, or filtration systems. Additionally, consider the mesh’s weaving pattern, which can affect its overall durability and performance in demanding applications.

Material Types and Their Benefits in Fine Metal Mesh

When selecting fine metal mesh for industrial or architectural projects, understanding the different material types and their corresponding benefits is crucial. Stainless steel mesh is one of the most widely used materials due to its excellent durability, corrosion resistance, and aesthetic appeal. According to a market report by Smithers Pira, the global market for stainless steel wire mesh is projected to reach $1.4 billion by 2025, highlighting its demand across various industries, including construction, automotive, and food processing. Its ability to withstand high temperatures makes it ideal for applications where structural integrity is essential.

Another popular option is aluminum mesh, known for its lightweight and versatility. It offers good protection against corrosion while being more cost-effective than stainless steel. Recent trends indicate that the use of aluminum fine mesh in filtration systems is increasing, particularly in the water treatment and HVAC sectors, where efficiency and lower operational costs are prioritized. A report from Freedonia Group suggests that the aluminum mesh market is expected to grow at a rate of 4.5% annually, driven by innovations in manufacturing processes that enhance its performance and accessibility.

Finally, copper mesh is gaining traction for its antimicrobial properties, making it suitable for healthcare environments. As detailed in a study published in the Journal of Hospital Infection, copper surfaces have been shown to significantly reduce microbial contamination in comparison to stainless steel. Given the increasing focus on hygiene in various settings, the use of copper fine mesh is likely to rise, positioning it as a beneficial option for projects that require both functionality and safety.

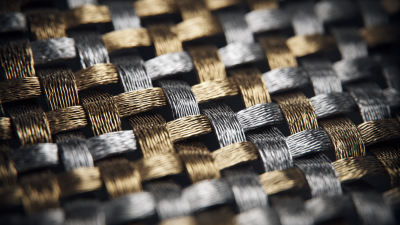

Mesh Specifications: Hole Size, Thickness, and Weave Patterns

When selecting fine metal mesh for your project, understanding mesh specifications is crucial. The hole size of the mesh determines the filtration or screening capabilities. Smaller holes are ideal for applications requiring higher precision, such as in laboratory settings or certain industrial processes, where they effectively filter out fine particles. Conversely, larger holes are appropriate for applications that demand more significant airflow or where the containment of larger objects is necessary. Therefore, assessing the size of the openings in relation to the intended use is fundamental to achieving optimal performance.

Thickness, or wire gauge, plays a significant role in the durability and strength of the mesh. Thicker wires will provide increased structural integrity and resistance to wear and tear, making them suitable for heavy-duty applications. However, they may limit flexibility and ease of shaping. When considering thickness, it's important to balance the need for strength with the desired flexibility for the application.

Weave patterns further influence the performance and aesthetic of the fine metal mesh. Common weave types include plain, twill, and dutch, each offering distinct characteristics in terms of openness, strength, and visual appeal. For example, a plain weave is typically easy to manufacture and provides uniform hole size, while a twill weave offers greater strength and flexibility, making it suitable for more intricate designs. Choosing the right weave pattern can enhance both the functionality and aesthetic value of the mesh in your project.

Top Tips for Choosing the Right Fine Metal Mesh for Your Project

| Material | Hole Size (mm) | Thickness (mm) | Weave Pattern | Applications |

|---|---|---|---|---|

| Stainless Steel | 0.5 | 0.3 | Plain Weave | Filtration, Decorative Applications |

| Aluminum | 1.0 | 0.5 | Dutch Weave | HVAC, Grilles |

| Copper | 0.8 | 0.4 | Twill Weave | Electronics, Art Installations |

| Brass | 0.6 | 0.35 | Plain Weave | Architectural Features, Lighting |

| Nickel | 0.3 | 0.2 | Multi-Layer Weave | Corrosive Environments, Filtration |

Common Industries That Utilize Fine Metal Mesh Solutions

Fine metal mesh solutions are widely used across various industries due to their unique properties such as durability, corrosion resistance, and versatility. In the aerospace sector, for instance, fine metal mesh is critical for applications like filters and screens that need to withstand extreme conditions while maintaining structural integrity. It is also utilized in the manufacturing of components that require high precision and reliability, making it an essential material for ensuring safety and performance in airborne crafts.

In the electronics industry, fine metal mesh is often employed in the production of devices requiring efficient electromagnetic interference (EMI) shielding. This is crucial for protecting sensitive components from external electromagnetic fields, ensuring optimal functionality and longevity of electronic products. Additionally, the automotive sector engages fine metal mesh for applications such as catalytic converters and exhaust systems, where efficient airflow and filtration are paramount for both performance and environmental compliance.

The pharmaceutical and food production industries also benefit from fine metal mesh solutions. Here, its ability to facilitate filtration processes while ensuring compliance with stringent health and safety regulations is invaluable. These industries rely on fine metal mesh for equipment that separates contaminants from products, ensuring safety and quality in their final outputs. As such, understanding the specific needs of each industry is essential for selecting the right fine metal mesh for any project.

Related Posts

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

2025 Top 5 Fine Metal Mesh Products for Enhanced Performance and Durability