The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

When it comes to industrial applications, the selection of appropriate materials is crucial for ensuring efficiency and durability. One such material that stands out in various filtration processes is stainless mesh.

Stainless mesh is not only known for its strength and resistance to corrosion, but it also offers varied performance characteristics depending on its type and structure. This guide will delve into the different types of stainless mesh available in the market, highlighting their unique properties and ideal usage scenarios.

Stainless mesh is not only known for its strength and resistance to corrosion, but it also offers varied performance characteristics depending on its type and structure. This guide will delve into the different types of stainless mesh available in the market, highlighting their unique properties and ideal usage scenarios.

By understanding the various stainless mesh options, industries can make informed decisions that enhance filtration efficiency and overall operational effectiveness, ensuring that they meet the stringent demands of their applications.

Whether you're looking for fine filtration or structural support, this comprehensive overview aims to equip you with the knowledge necessary to choose the right stainless mesh for your specific needs.

Understanding the Various Types of Stainless Steel Mesh Used in Industry

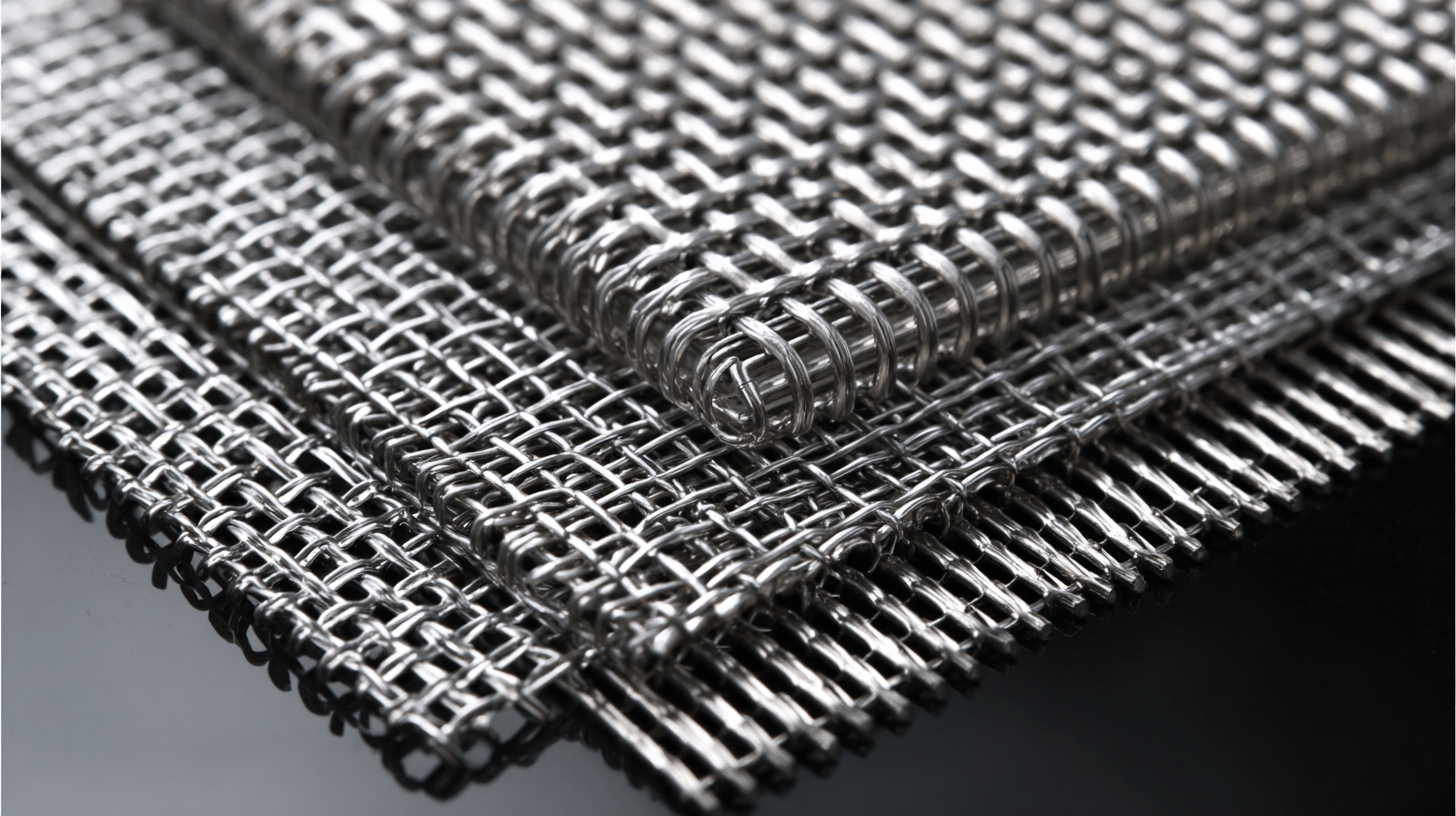

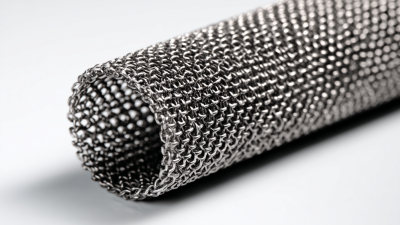

When selecting stainless steel mesh for industrial applications, it is essential to understand the various types available and their specific properties tailored for filtration efficiency. Stainless steel mesh is categorized primarily into woven wire mesh and welded wire mesh, each serving distinct purposes in different environments. Woven wire mesh provides flexibility and is often utilized in applications requiring high strength and durability, such as filtration systems in wastewater treatment or for supporting structures in construction. On the other hand, welded wire mesh offers robust support and is commonly used in construction and reinforcement applications.

Recent advancements in stainless steel mesh technology include innovations that enhance its application in environmental solutions. For instance, electrocoagulation and electrocatalysis processes utilizing stainless steel mesh cathodes coated with ultrathin materials have demonstrated potential in improving wastewater treatment efficiency. These developments highlight the importance of selecting the right type of stainless steel mesh, not only for structural integrity but also for optimizing filtration processes in industrial contexts. Understanding these characteristics allows engineers and industry professionals to make informed decisions that contribute to both efficiency and environmental sustainability.

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications

This chart illustrates the filtration efficiency of various types of stainless steel mesh used in industrial applications based on their micron ratings. As the micron rating decreases, the filtration efficiency increases, showcasing the effectiveness of finer mesh sizes.

Key Characteristics that Define Filtration Efficiency in Stainless Steel Mesh

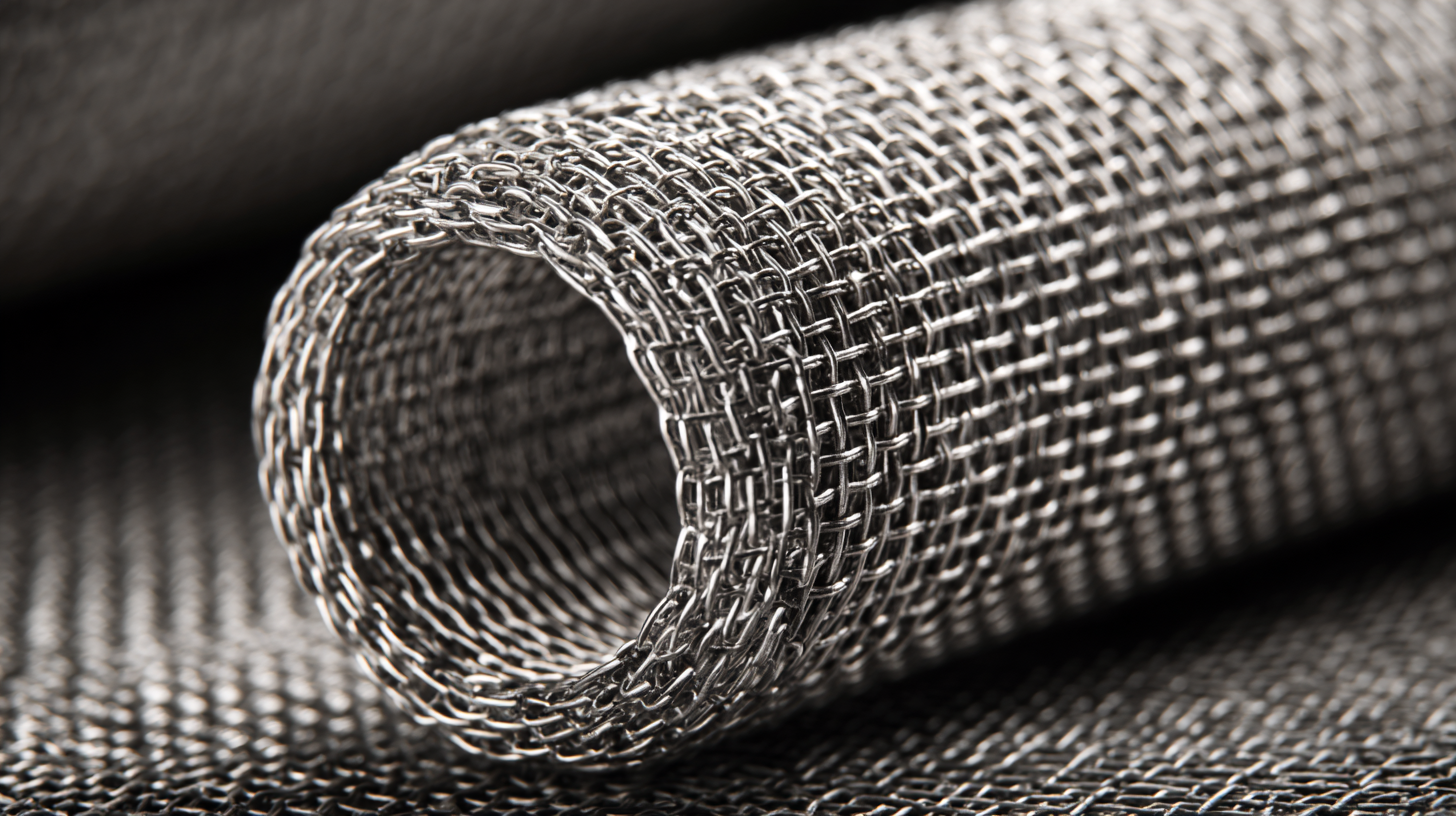

When selecting stainless steel mesh for industrial applications, understanding the key characteristics that define filtration efficiency is essential. The mesh's wire diameter, weave pattern, and overall construction significantly influence performance. A finer wire diameter can enhance filtration by allowing smaller particles to be captured, but it may also reduce the structural integrity or flow rate. Therefore, striking a balance between wire thickness and desired filtration level is crucial for optimizing efficiency.

Another critical aspect is the mesh's openings. The size and shape of these openings determine the mesh's ability to separate particles based on size while maintaining adequate flow. A uniform opening size ensures consistent filtration, reducing the risk of clogging or bypassing. Additionally, considering the mesh's material properties—such as resistance to corrosion, pressure, and temperature—will further enhance its effectiveness in diverse industrial settings. Prioritizing these characteristics will guide the selection process and lead to improved filtration efficiency in various applications.

Comparative Analysis: Woven Mesh vs. Welded Mesh for Industrial Applications

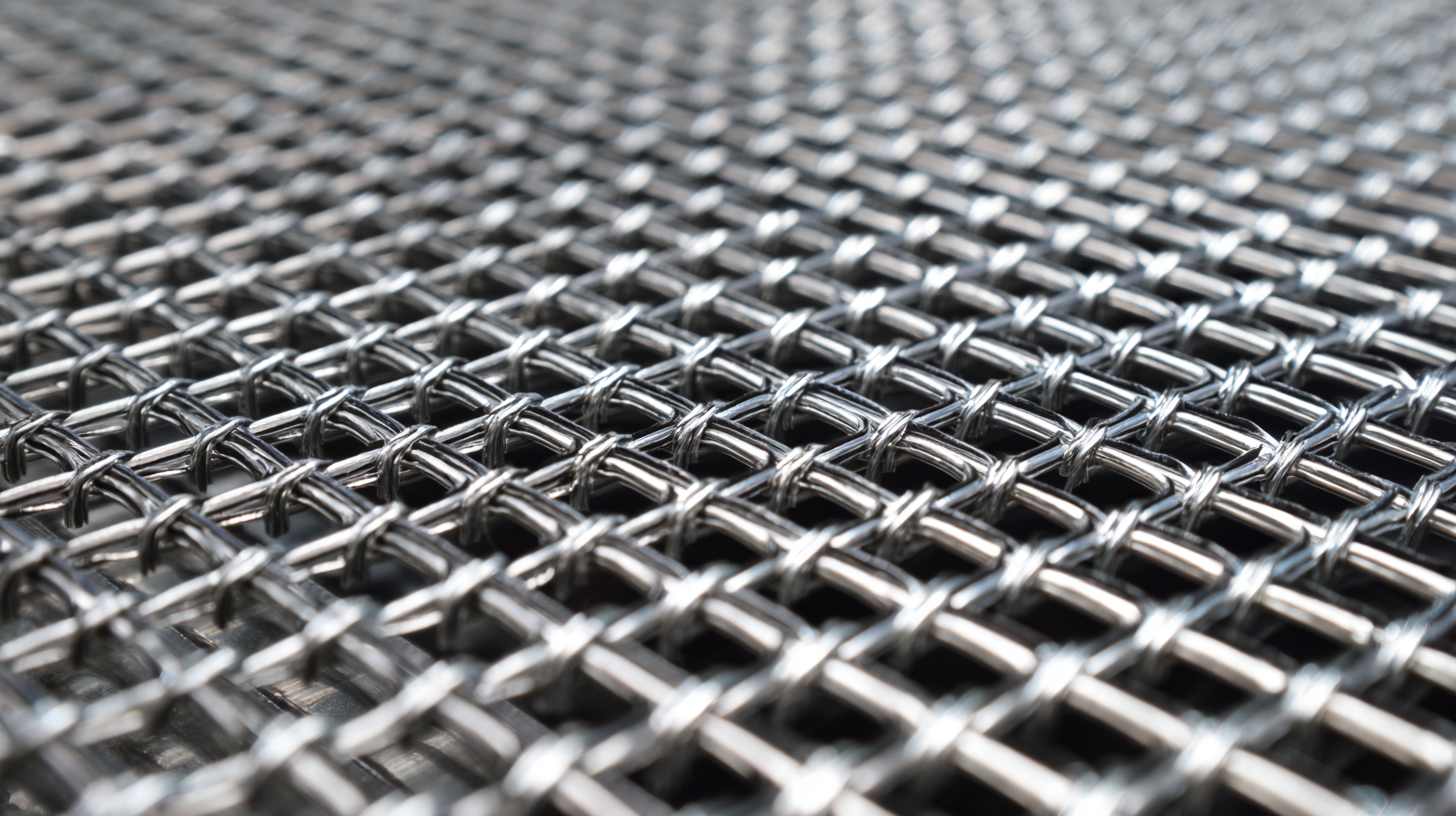

When selecting the right type of stainless mesh for industrial applications, understanding the differences between woven and welded mesh is crucial for achieving optimal filtration efficiency. Woven mesh, created from interlacing wire strands, offers versatility in size and design, making it suitable for various applications where flexibility is desired. Its structure allows for greater airflow and fluid passage, which is advantageous in filtration processes. The varying weave patterns can also provide different levels of filtration precision, catering to the specific needs of industries ranging from food processing to pharmaceuticals.

On the other hand, welded mesh embodies rigidity and durability, with each junction of the wires being fused together. This type of mesh is particularly effective in applications requiring strength and structural integrity, such as in construction and heavy machinery. Its uniform aperture size can result in consistent filtration results, reducing the risk of clogging and ensuring long-lasting performance. Both woven and welded meshes come with distinct advantages and are selected based on specific requirements, highlighting the importance of understanding their comparative characteristics to enhance efficiency and effectiveness in industrial filtration scenarios.

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

| Mesh Type | Filtration Efficiency (%) | Open Area (%) | Durability Rating | Cost ($/m²) |

|---|---|---|---|---|

| Woven Mesh | 95 | 60 | High | 25 |

| Welded Mesh | 89 | 70 | Medium | 20 |

| Perforated Sheet | 80 | 50 | Low | 18 |

| Expanded Metal | 76 | 65 | Medium | 22 |

Evaluating Mesh Size and Opening Patterns for Optimal Filtration Performance

When it comes to selecting stainless mesh for industrial applications, the size of the mesh and the pattern of openings are critical factors that directly influence filtration efficiency. Research indicates that mesh sizes can vary significantly, typically ranging from 1 micron to over 6 millimeters. A finer mesh captures smaller particles, which is essential in industries like pharmaceuticals and food processing where purity is paramount. On the other hand, coarser meshes are suitable for applications where larger debris needs to be filtered, such as in mining or wastewater treatment.

Tips: When choosing mesh size, consider the specific contaminants present in your application. A particle size analysis can provide valuable insight into what mesh size will yield the best results in filtration.

The opening patterns of the mesh also play a pivotal role in determining the filtration performance. Patterns such as twill weave and plain weave offer different stress distribution and fluid flow characteristics. According to the American Filtration and Separations Society, optimal mesh design can lead to an increase in flow rates by up to 25% without sacrificing particle retention. This balance of performance is crucial, particularly in high-volume industries.

Tips: Evaluate not just the size but also the weave pattern of the mesh. Consulting filtration specialists can help ensure you're making informed decisions based on the materials being processed and desired outcomes.

Factors to Consider When Selecting Stainless Steel Mesh for Specific Industries

When selecting stainless steel mesh for industrial applications, several critical factors must be taken into consideration to ensure optimal filtration efficiency. One of the foremost considerations is the mesh size, which directly impacts the filtration capability. According to a report by the American Filtration and Separations Society, choosing the right mesh size can affect particle retention efficiency by as much as 40%. For instance, a mesh with a smaller opening is preferred in industries such as food processing, where the removal of fine particles is essential to maintain product quality.

Another significant factor is the wire diameter, as it influences both the strength and flexibility of the mesh. In high-stress applications, such as mining and construction, a thicker wire diameter can provide the necessary durability to withstand harsh conditions. A study conducted by the Industrial Filtration Division noted that utilizing a higher wire diameter could enhance the mesh’s lifespan by up to 30%, reducing the frequency of replacements in demanding environments. Additionally, considering the specific corrosion resistance properties of different stainless steel grades can ensure longevity, especially in chemical processing environments where exposure to aggressive substances is common.

Related Posts

-

How to Choose the Right Stainless Mesh for Your Specific Applications

-

How to Choose the Right Wire and Cable for Your Electrical Projects

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Perfect Fireplace Screen for Your Home Decor

-

How to Choose the Right Metal Screen for Your Project

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data