The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

In today's industrial landscape, the selection of the right stainless steel cable is pivotal for the success of various projects, ranging from construction to marine applications. According to a report by Grand View Research, the global stainless steel wire rope market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 5.2%. This growth is fueled by the material's exceptional strength-to-weight ratio, corrosion resistance, and versatility, making stainless steel cable a prime choice for heavy-duty applications. However, with a wide array of options available, from differing grades of stainless steel to various constructions and finishes, choosing the most suitable cable can be daunting. Understanding the types of stainless steel cables and their respective properties is crucial for ensuring safety, durability, and efficiency in any project. This guide aims to demystify the complexities of stainless steel cable selection, helping you make informed decisions tailored to your specific needs.

Essential Factors to Consider When Selecting Stainless Steel Cable for Durability and Strength

When selecting stainless steel cable for your project, it’s crucial to consider essential factors that ensure durability and strength. The composition of the stainless steel plays a significant role in its corrosion resistance and tensile strength. High-quality cables, made from appropriate grades of stainless steel, are designed to withstand harsh environmental conditions, making them ideal for outdoor or marine applications.

Additionally, the diameter and construction of the cable should match the specific demands of your project. A thicker cable provides greater strength but may also be heavier and more challenging to work with. It's important to balance these characteristics based on the project requirements, whether it's for structural support, decorative purposes, or safety applications. With the stainless steel market projected to grow significantly, reaching an expected value of $320.37 billion by 2032, choosing the right cable can also offer a competitive edge in terms of performance and longevity.

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

| Cable Type | Diameter (mm) | Breaking Strength (kg) | Corrosion Resistance | Applications |

|---|---|---|---|---|

| 7x19 | 3.2 | 1470 | Excellent | Rigging, Marine |

| 1x19 | 4.0 | 1960 | Good | Structural, Lifting |

| 7x7 | 5.0 | 1960 | Fair | Cable Railings, Lifting |

| Flexibility Cable | 2.5 | 1000 | Excellent | Bicycle Lock, Artwork |

Understanding Different Stainless Steel Grades: Which is Best for Your Application?

When selecting stainless steel cables for your project, understanding the various grades available is crucial. Stainless steel is categorized into several grades, each with unique properties that make it suitable for specific applications. For instance, Type 304 is the most common, known for its excellent corrosion resistance and versatility, making it ideal for general purposes. On the other hand, Type 316 offers enhanced resistance to salt water and chemicals, making it perfect for marine applications.

Tip: Always consider the environment in which the cable will be used. If your project involves exposure to harsh conditions, opt for higher-grade stainless steel like 316 to ensure longevity and durability.

Additionally, the diameter and construction of the cable can significantly affect its strength and flexibility. For heavy-duty applications, thicker cables are recommended, while lighter projects may benefit from thinner, more flexible options.

Tip: Conduct a thorough analysis of the load requirements and environmental factors before purchasing to ensure the best performance of your stainless steel cable.

Evaluating Cable Diameter: Key Insights on Load Capacity and Flexibility

When it comes to selecting the right stainless steel cable for your project, understanding cable diameter is crucial. The diameter of the cable directly influences its load capacity and flexibility, both of which are essential factors in various applications. According to the International Standards Organization (ISO), the standard load capacity of stainless steel cables increases significantly with diameter. For instance, a cable with a diameter of 1/8 inch can typically handle around 1,200 pounds of tension, whereas a 1/4 inch diameter cable can support approximately 4,000 pounds. This scaling effect indicates that choosing the appropriate diameter can enhance safety and efficiency in load-bearing scenarios.

Moreover, flexibility plays a vital role in the functionality of stainless steel cables, especially in applications involving tight bends or intricate setups. Data from the Wire Rope Technical Board shows that thinner cables are generally more flexible and can navigate around curves more easily. However, thinner cables come with a trade-off in terms of load capacity. For example, while a 3/16 inch cable may offer enhanced flexibility for complex installations, it has a lower load capacity compared to a thicker cable. Understanding these dynamics not only aids in selecting the right cable but also ensures that projects are designed with the ideal balance between strength and flexibility, thereby meeting both manufacturing and safety standards effectively.

The Ultimate Guide to Choosing the Right Stainless Steel Cable

This chart illustrates the relationship between cable diameter, load capacity, and flexibility. As the diameter increases, the load capacity tends to increase while flexibility decreases. This data is essential for making informed choices for your project.

Corrosion Resistance in Stainless Steel Cables: A Guide to Environmental Suitability

When selecting stainless steel cables for various projects, understanding corrosion resistance is paramount. Stainless steel is widely recognized for its durability and strength, but not all stainless steel grades offer the same level of corrosion resistance. Factors such as the environmental conditions, exposure to chemicals, and moisture levels play crucial roles in determining the right type of stainless steel cable to use. This is especially important in applications requiring longevity and minimal maintenance, such as marine environments, construction projects, and industrial settings.

The selection of stainless steel cables should also consider the specific environmental challenges they will face. For example, cables used in coastal areas must withstand saltwater corrosion, while those in industrial sites may need to resist chemical exposure. By assessing the environmental suitability of the stainless steel used in cables, project managers can make informed decisions that enhance the longevity and reliability of their installations. As the cable market continues to grow, the emphasis on choosing the right type of stainless steel cable that meets specific corrosion resistance requirements will become increasingly critical for successful project outcomes.

Cost-Effectiveness of Stainless Steel Cables: Balancing Quality and Budget for Projects

When selecting stainless steel cables for various projects, balancing cost-effectiveness with quality is essential. Recent industry reports highlight that high-grade stainless steel cables, though initially more expensive, typically offer greater longevity and durability. For example, cables constructed from marine-grade stainless steel can last up to 30 years in harsh environments, significantly reducing the need for frequent replacements and associated labor costs. This long-term perspective underscores the importance of investing in quality materials, especially for projects where safety and reliability are paramount.

Moreover, just as in the world of speaker cables, where a slight increase in price can lead to considerable enhancements in performance, the same applies to stainless steel cables. A report by the International Stainless Steel Forum indicates that the investment in high-quality stainless steel, when applied correctly, can yield results that justify the upfront costs, particularly in industries requiring robust, corrosion-resistant solutions. This balance of quality and budget is crucial for projects aiming for both efficiency and sustainability, ensuring that clients receive the best possible return on their investment while minimizing future expenditures.

Related Posts

-

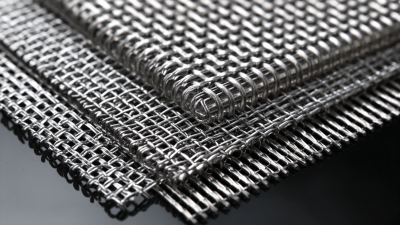

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right Woven Wire for Your Project Needs

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

How to Choose the Right Wire and Cable for Your Electrical Projects