Why Use Fine Metal Mesh Screen for Effective Filtration Solutions

In the ever-evolving landscape of filtration technology, the importance of selecting the right materials cannot be underestimated. As industry experts continue to seek effective filtration solutions, the fine metal mesh screen emerges as a pivotal component owing to its superior performance and versatility. Dr. Emily Carter, a renowned filtration specialist, asserts, "The durability and precision of fine metal mesh screens make them indispensable for applications requiring both efficiency and reliability." This statement highlights the growing recognition of fine metal mesh screens in diverse sectors, from environmental management to industrial processes.

Fine metal mesh screens are designed to provide exceptional filtration, trapping contaminants while allowing for a smooth flow of liquids and gases. Their fine aperture sizes can be tailored to meet specific filtration needs, ensuring that even the smallest particles are captured. As industries face increasing regulations and environmental challenges, the demand for effective filtration solutions has never been greater. The adaptability of fine metal mesh screens positions them as a front-running choice in achieving compliant and sustainable operational practices.

As we delve deeper into the multifaceted advantages of fine metal mesh screens, it becomes clear that their role transcends mere functionality; they embody a strategic choice for businesses striving for enhanced filtration efficiency and cost-effectiveness.

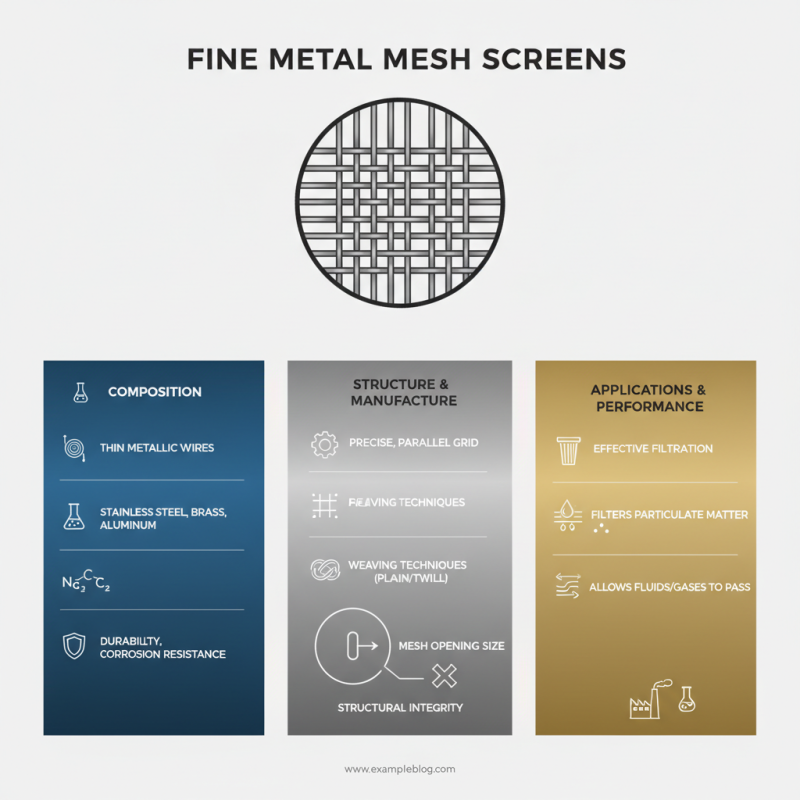

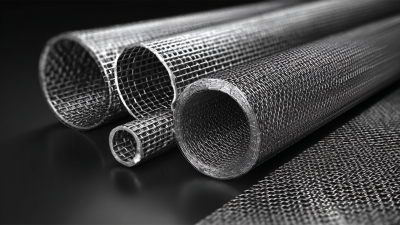

Understanding Fine Metal Mesh Screen and Its Composition

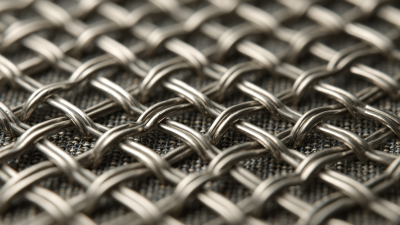

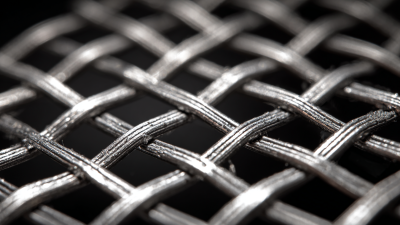

Fine metal mesh screens are composed of thin metallic wires arranged in a precise, parallel grid, allowing for effective filtration across a variety of applications. The composition typically includes various types of metals such as stainless steel, brass, or aluminum, which contribute to durability, corrosion resistance, and a high level of structural integrity. The weaving techniques utilized in the manufacture of these screens can significantly influence their mesh opening size and overall filter performance, ensuring that they can adeptly filter out particulate matter while allowing necessary fluids or gases to pass through.

The effectiveness of fine metal mesh screens lies in their ability to capture a wide range of contaminants, from larger particles to finer debris, without compromising flow rates. Their versatility enables usage in various industries, including pharmaceuticals, food and beverage, and water treatment. The customization options available for mesh size, material type, and coating further enhance their applicability, making them a preferred choice for engineers and manufacturers seeking reliable filtration solutions. This adaptability, combined with their inherent strength and longevity, makes fine metal mesh screens an essential component in modern filtration systems.

Key Advantages of Fine Metal Mesh in Filtration Applications

Fine metal mesh screens have become a go-to solution for various filtration applications due to their remarkable advantages over traditional materials. One of the primary benefits is their exceptional durability, which is supported by data from the Filtration Society, indicating that metal mesh can endure temperatures ranging from -200°C to over 1000°C. This resilience ensures longer service life and reduced replacement costs compared to plastic or fabric filters, which often succumb to environmental wear and tear. Additionally, fine metal mesh screens boast higher chemical resistance, making them suitable for a wide range of industrial processes, including those in the pharmaceutical and chemical sectors.

Moreover, the efficiency of fine metal mesh in filtration is noteworthy. According to a study published in the Journal of Membrane Science, fine metal meshes can achieve filtration efficiencies exceeding 99%, depending on the particle size and mesh configuration. This level of efficiency is critical in applications where product purity is paramount, such as in the food and beverage industry. The ability to customize mesh sizes allows for tailored solutions that can capture particles as small as a few microns while maintaining optimal flow rates, which is a significant advantage over conventional filter media. Thus, the combination of durability, chemical resilience, and filtration efficiency makes fine metal mesh screens an ideal choice for effective filtration solutions across various industries.

Advantages of Fine Metal Mesh Screen in Filtration Applications

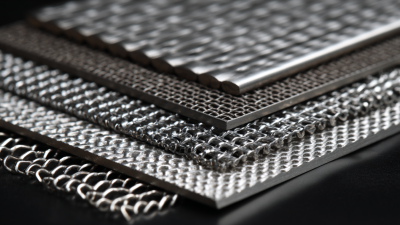

Comparative Analysis: Fine Metal Mesh vs. Other Filtration Media

When evaluating filtration solutions, fine metal mesh screens demonstrate significant advantages over traditional filtration media like paper filters and activated carbon. A recent study indicated that fine metal mesh can achieve filtration efficiencies exceeding 99%, effectively capturing particles as small as 1 micron. This surpasses the capabilities of many standard filters, which typically range from 70-90% efficiency at larger particle sizes. The durability and reusability of fine metal mesh contribute to its effectiveness, allowing for consistent filtration performance without the rapid degradation seen in some organic materials.

Additionally, fine metal mesh screens show remarkable resistance to wear and thermal fluctuations, making them suitable for demanding industrial applications. Reports suggest that filters made from fine metal can endure temperatures up to 500°F (260°C) without structural compromise, while conventional options may fail under similar conditions, leading to increased downtime and replacement costs. Furthermore, fine metal mesh facilitates easier cleaning regimes, reducing overall maintenance time by up to 30% compared to paper and synthetic media. This blend of efficiency, longevity, and maintenance simplicity positions fine metal mesh as a superior choice in the landscape of filtration technologies.

Applications of Fine Metal Mesh in Various Industries

Fine metal mesh screens are increasingly recognized for their versatility and effectiveness across various industries, owing to their unique properties that make them ideal for advanced filtration solutions. In the aerospace sector, for example, fine metal mesh is employed to filter fuel and lubricants, ensuring that impurities do not compromise engine performance. According to a report by the Aerospace Industries Association, effective filtration systems can enhance the efficiency of aircraft operations, contributing to significant savings and improved safety measures.

In the pharmaceutical industry, the demand for high-purity filtering solutions is critical. Fine metal mesh screens play a crucial role in processes such as vaccine production and sterile fluid transfer. A study published in the Journal of Pharmaceutical Sciences highlights that using metal mesh filters can reduce contamination rates by up to 98%, significantly improving the quality of final products. Additionally, the food and beverage sector benefits from fine metal mesh by employing it in brewing and beverage clarification processes. The Food and Beverage Manufacturers Association reports that employing metal mesh filters not only enhances product clarity but also ensures compliance with stringent safety regulations.

Furthermore, in the electronics industry, the use of fine metal meshes in the production of semiconductors aids in the filtration of chemicals and contaminants that can affect device performance. A study from the Semiconductor Industry Association notes that efficient filtration is vital for maintaining the integrity and reliability of electronic components. The adoption of fine metal mesh technology in these applications showcases its integral role in enhancing process efficiency and safety across diverse sectors, establishing it as a preferred choice for effective filtration solutions.

Maintenance and Durability of Fine Metal Mesh Filters

Fine metal mesh filters are increasingly recognized for their maintenance and durability, providing effective filtration solutions across various industries. These filters are often characterized by their resilience and longevity, attributed to the high-quality metals used in their construction, such as stainless steel or specialized alloys. According to a report from the Filtration Society, metal mesh filters can endure extreme temperatures and harsh chemicals, outperforming traditional filter materials which often succumb to wear and degradation. In fact, studies indicate that fine metal mesh can last up to five times longer than conventional filters, significantly reducing the frequency of replacements and associated downtime.

The ease of maintenance of fine metal mesh filters further enhances their appeal. Cleaning and reusing these filters is both simple and cost-effective, as they can be easily immersed in cleaning solutions or back-flushed without compromising their structural integrity. A report from the Society of Manufacturing Engineers highlights that regular maintenance of metal mesh filters can improve operational efficiency by up to 20%, as they maintain consistent flow rates and do not contribute to clogging issues often seen with other filter types. Not only do these properties lead to lower operational costs, but they also foster a more sustainable approach to filtration, minimizing waste and the need for frequent part replacements. This makes fine metal mesh screens an optimal choice for industries requiring dependable and long-lasting filtration solutions.

Why Use Fine Metal Mesh Screen for Effective Filtration Solutions - Maintenance and Durability of Fine Metal Mesh Filters

| Filter Material | Filtration Efficiency (%) | Maximum Operating Temperature (°C) | Corrosion Resistance | Maintenance Frequency (months) | Expected Lifespan (years) |

|---|---|---|---|---|---|

| Stainless Steel | 95 | 400 | Excellent | 12 | 10 |

| Bronze | 90 | 250 | Good | 6 | 8 |

| Aluminum | 85 | 200 | Fair | 12 | 5 |

| Nickel | 92 | 350 | Excellent | 8 | 12 |

Related Posts

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

Exploring the Benefits of Fine Mesh Filters in Sustainable Home Brewing

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

Exploring the Versatility of Stainless Steel Mesh in Modern Applications

-

2025 Top 5 Fine Metal Mesh Products for Enhanced Performance and Durability

-

How to Choose the Right Wire Mesh Products for Your Project Needs