What is Fine Mesh and How is it Used in 2026 Top Types?

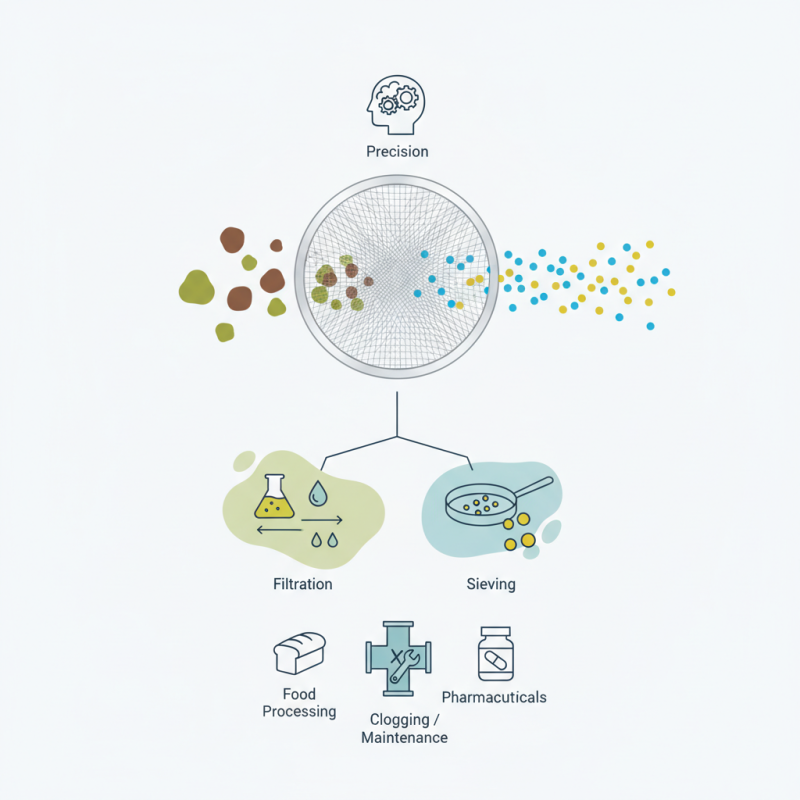

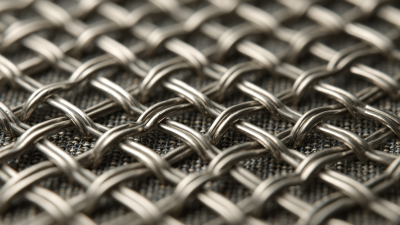

In the world of manufacturing and design, fine mesh plays a crucial role. As an expert in the field, Dr. Jane Thompson emphasizes, “Fine mesh is essential for precision and functionality.” This statement highlights the importance of fine mesh in various applications. From filtration to sieving, its uses are extensive and varied.

Fine mesh is commonly employed in industries such as food processing and pharmaceuticals. It ensures that small particles are effectively separated from larger materials. The versatility of fine mesh allows for a wide range of applications. However, the varying mesh sizes can lead to confusion. Users must choose wisely to meet specific needs.

Despite its advantages, there are challenges. Fine mesh can sometimes clog, requiring regular maintenance and attention. This can be an area for improvement. Understanding the types and uses of fine mesh is vital for achieving optimal results. Through this exploration, the significance of fine mesh in various sectors becomes clear.

Definition and Characteristics of Fine Mesh

Fine mesh refers to a screening material with very small openings. These openings can measure as little as 0.1 millimeters. This characteristic allows fine mesh to filter out particles very effectively. According to industry reports, the demand for fine mesh screens is expected to grow by 7% annually by 2026.

The primary use of fine mesh is in sectors like food and beverage, pharmaceuticals, and electronics. It helps maintain product quality by preventing contamination. Workers in these industries often rely on fine mesh screens to ensure consistency. Yet, small mesh sizes can sometimes lead to clogging. Regular maintenance and cleaning are necessary, which can be labor-intensive.

In construction, fine mesh is used for both reinforcement and filtering. It can prevent debris from contaminating materials like concrete. However, there is a rising concern about its durability over time, especially under harsh conditions. As more industries adopt fine mesh technology, these durability issues could impact overall performance. Further research is needed to enhance its application, focusing on materials that offer both strength and flexibility.

Applications of Fine Mesh Across Various Industries

Fine mesh is a versatile material used across several industries. It consists of tightly woven fibers or materials with very small openings. This characteristic allows fine mesh to filter particles effectively. In construction, fine mesh often screens dust and debris. This creates a cleaner work environment. However, using fine mesh can sometimes lead to clogs.

In the food industry, fine mesh plays a crucial role. It helps in the filtration of liquids and solids. For instance, when brewing coffee, fine mesh ensures a smooth texture. However, over-reliance on fine mesh in food processing could result in excess waste. Some materials, when filtered excessively, lose flavor or texture.

Fine mesh is also important in healthcare. It provides protection in sterile environments. For instance, lab processes often need fine mesh to prevent contamination. However, if the mesh is not regularly maintained, it becomes less effective. Regular checks are necessary to ensure optimal performance. The indiscriminate use of fine mesh may sometimes lead to overlooked maintenance issues. This could affect productivity and safety.

Applications of Fine Mesh in Various Industries

Top Types of Fine Mesh Used in 2026

Fine mesh refers to a type of fabric with very small openings. It has diverse applications, especially in industries like food, pharmaceuticals, and agriculture. In 2026, the use of fine mesh has evolved further, becoming integral across various sectors.

One popular type of fine mesh is used in air filtration. It helps to capture tiny particles and allergens. This offers a cleaner environment. Another type is used in gardening. It protects plants from pests while allowing sunlight and water to pass. This balance is crucial for healthy growth.

**Tips**: When choosing fine mesh materials, consider the size of the openings. Smaller openings may block light or airflow. Find a balance that suits your specific needs. Quality matters too; a low-quality mesh can wear out quickly, leading to frustration.

Some applications are not perfect. For instance, using fine mesh in brewing can lead to a slow process. It may frustrate some brewers. Look for alternatives to avoid these pitfalls. Explore options that can offer efficiency while still being effective.

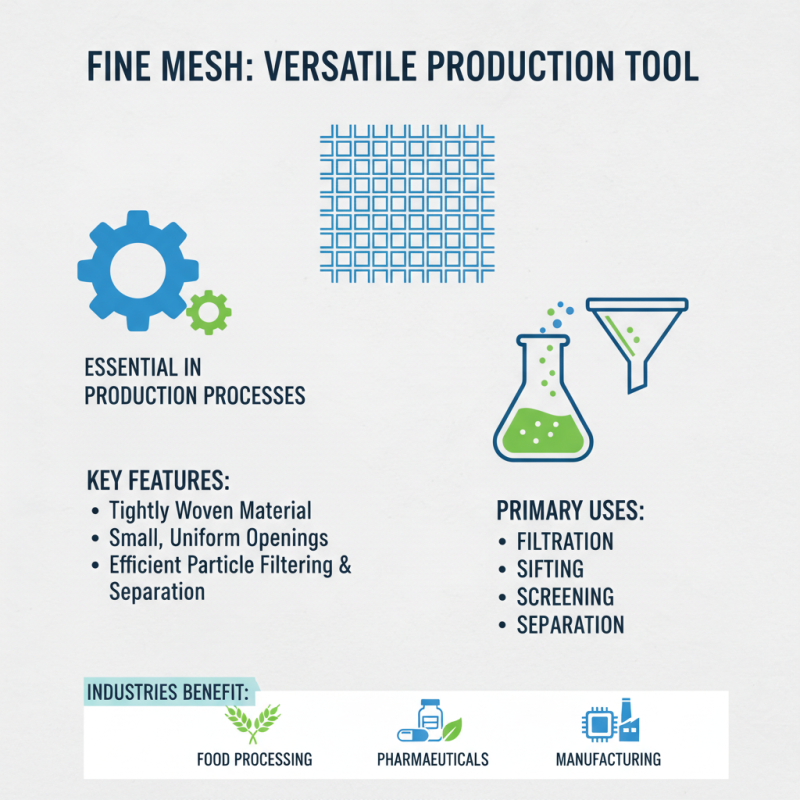

Benefits of Using Fine Mesh in Production Processes

Fine mesh is an essential tool in various production processes, known for its versatility. It consists of tightly woven materials that create small openings. This feature allows for efficient filtering and separation of particles. Many industries benefit from fine mesh, including food processing and pharmaceuticals.

Using fine mesh brings several advantages. It improves product quality by ensuring the separation of unwanted particles. This results in cleaner, safer products. Additionally, fine mesh can enhance airflow in applications such as drying and sieving. It can also reduce waste, optimizing the production process.

Tip: When selecting fine mesh, consider the specific requirements of your process. The right mesh size can significantly impact your results.

Keep in mind that not all fine mesh is created equal. It’s crucial to test different types to find the best fit for your needs. Sometimes, the ideal mesh may not be obvious. Reflection on past choices can lead to better decisions.

Tip: Regular maintenance of fine mesh equipment is vital. Neglect can lead to clogs and inefficiencies. Cleaning and inspection should be routine.

Future Trends in Fine Mesh Technologies and Innovations

Fine mesh technology is evolving rapidly. In 2026, it's set to improve in various fields. Industries like food processing and pharmaceuticals will benefit greatly. These developments promise enhanced filtration and separation capabilities. The focus is on sustainability and efficiency.

Innovations in fine mesh materials are on the rise. More durable and versatile options are being explored. Researchers are experimenting with different fibers and weaves. However, challenges remain. Balancing cost and performance is not easy. Companies may struggle to keep up with evolving standards.

Emerging technologies in fine mesh could reshape manufacturing processes. Automation can enhance precision in mesh production. Yet, reliance on tech increases risks. Human oversight is still crucial. Designers are learning to adapt to new issues as they arise. It's an exciting yet daunting time for fine mesh technology.

What is Fine Mesh and How is it Used in 2026 Top Types? - Future Trends in Fine Mesh Technologies and Innovations

| Mesh Type | Material | Usage Applications | Innovation Trends | Market Growth (%) |

|---|---|---|---|---|

| Polyester Mesh | Polyester | Food Industry, Filtration | Sustainable Materials, Biodegradable Options | 15% |

| Stainless Steel Mesh | Stainless Steel | Automotive, Aerospace | Corrosion Resistance, Enhanced Strength | 10% |

| Nylon Mesh | Nylon | Medical, Sports Equipment | Lightweight Materials, Customizable Designs | 12% |

| Wire Mesh | Copper, Aluminum | Construction, Security Applications | Smart Mesh Technologies, Anti-Tampering Features | 8% |

| Fiberglass Mesh | Fiberglass | Construction, Insulation | Eco-Friendly Options, Thermal Resistance | 5% |

Related Posts

-

Exploring the Benefits of Fine Mesh Filters in Sustainable Home Brewing

-

Why Use Fine Metal Mesh Screen for Effective Filtration Solutions

-

Top Tips for Choosing the Right Fine Metal Mesh for Your Project

-

Top Uses of Stainless Steel Cable for Your Next Project

-

How to Effectively Filter Media Content for Your Online Audience

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!