Top 10 Essential Tips for Choosing the Right Wire & Cable for Your Projects

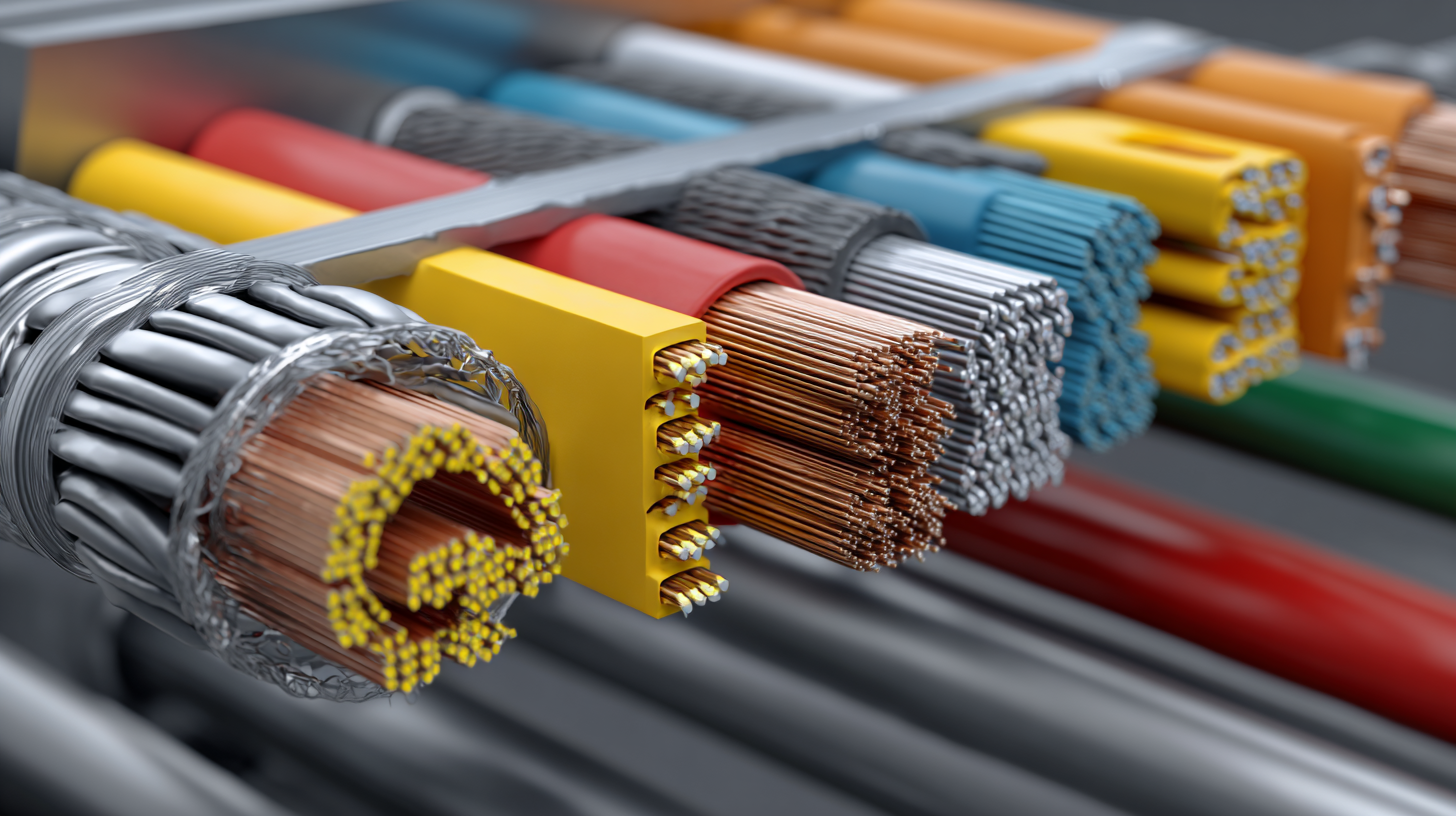

In the ever-evolving world of electrical engineering, selecting the right wire and cable is crucial for the success of any project. As noted by industry expert John Smith, a leading specialist in the wire and cable sector, “The foundation of any electrical system lies in the quality and appropriateness of the wire and cable used.” This highlights the importance of making informed choices when it comes to wiring solutions, as the right materials can ensure safety, efficiency, and durability in various applications.

Choosing the appropriate wire and cable can be a daunting task, given the multitude of options available today. From power distribution to telecommunications, each application has specific requirements that must be met to achieve optimal performance. Understanding these needs and the characteristics of different wire and cable types is essential for both professionals and DIY enthusiasts alike. Whether you are undertaking a large-scale industrial installation or a small residential project, knowing the key factors to consider can prevent costly mistakes and enhance the longevity of your work.

In this guide, we will explore the top 10 essential tips for choosing the right wire and cable for your projects. Each tip is designed to equip you with the knowledge needed to navigate the complexities of wire and cable selection, ensuring that your projects are both successful and compliant with industry standards.

Understanding Wire Gauge: Importance of Proper Sizing for Current Capacity

When selecting the appropriate wire and cable for any project, understanding wire gauge is paramount. Wire gauge refers to the thickness of the wire, which directly affects its current-carrying capacity. A wire that is too thin for the intended load can overheat, leading to potential failure or fire hazards. Conversely, a thicker wire may be unnecessarily expensive and rigid, complicating installation. Therefore, determining the right gauge is essential for both safety and functionality.

The American Wire Gauge (AWG) system is commonly used in the United States to classify wire sizes. Lower gauge numbers indicate thicker wires, while higher numbers refer to thinner wires. For example, a 10 AWG wire can handle more current than a 20 AWG wire. To accurately choose the appropriate wire gauge, it is crucial to first understand the project's voltage, current requirements, and distance the electricity must travel. By considering these factors, one can ensure that the selected wire will efficiently transmit power without risk, optimizing performance while maintaining safety standards.

Top 10 Essential Tips for Choosing the Right Wire & Cable for Your Projects

| Tip Number | Tip Description | Wire Gauge (AWG) | Current Capacity (Amps) | Best Application |

|---|---|---|---|---|

| 1 | Understand the importance of wire gauge | 12 AWG | 20 Amps | Residential wiring |

| 2 | Select the correct insulation type | 14 AWG | 15 Amps | General purpose |

| 3 | Consider the length of the run | 10 AWG | 30 Amps | Heavy machinery |

| 4 | Evaluate the environment | 8 AWG | 40 Amps | Outdoor installations |

| 5 | Mind the temperature ratings | 6 AWG | 55 Amps | Commercial heating |

| 6 | Use proper connectors | 4 AWG | 70 Amps | Battery installation |

| 7 | Ensure the cable is UL-listed | 2 AWG | 95 Amps | Industrial applications |

| 8 | Check for flexibility | 1 AWG | 105 Amps | Portable devices |

| 9 | Assess voltage drop | 3 AWG | 85 Amps | Long runs |

| 10 | Consider future expansion needs | 0 AWG | 120 Amps | New constructions |

Evaluating Cable Insulation: Selecting Materials for Environment and Safety

When evaluating cable insulation for various projects, selecting the right materials based on the environment and safety requirements is crucial. Innovations in insulation materials are increasingly influenced by the growing focus on renewable energy sources such as solar, wind, and hydropower. These materials must not only ensure optimal performance and durability but also support the overall sustainability goals of modern projects. By choosing environmentally friendly insulation materials, project developers can contribute to reducing the carbon footprint while enhancing the safety and reliability of electrical systems.

Collaboration between cable manufacturers and compound suppliers is pivotal in advancing the quality and safety of cable products. For instance, companies are now developing cables with advanced fire-retardant properties, thanks to the use of innovative compounds such as those incorporating alumina trihydrate. These efforts are essential not only for compliance with safety standards but also for addressing the increasing demand for safer, more sustainable wiring solutions in both residential and industrial applications. As markets evolve, prioritizing ecological and safety considerations in cable insulation will play a significant role in driving growth within the industry.

Voltage Ratings Explained: Ensuring Compatibility with Project Requirements

When selecting the right wire and cable for your projects, understanding voltage ratings is crucial. As advancements in technology push for higher voltage systems, such as the EU-funded ENLIGHTEN project aiming for 1200V powertrains, it's essential to ensure that the components you choose can handle these demands. Voltage ratings determine the maximum electrical potential that a cable can safely manage without risk of failure. For instance, recent developments have seen systems verified for 2000V compatibility, indicating a significant capability for solar installations, which can lead to improved efficiency and reduced costs.

When choosing cables, consider these essential tips: first, always check the voltage rating specified for your application to prevent overheating or insulation breakdown. Additionally, selecting cables that exceed your project's voltage requirements by a safe margin allows for unexpected fluctuations in electrical demand. It's also wise to consult technical evaluations and industry reports that specifically point out compatibility with high-voltage systems. As photovoltaic technology evolves, making informed decisions on wire and cable specifications will enhance safety and performance in any electrical application.

Voltage Ratings Comparison for Wire & Cable Selection

Environmental Factors: Choosing Cables for Optimal Performance in Specific Conditions

When selecting wires and cables for specific environmental conditions, it is crucial to consider factors such as temperature, humidity, chemical exposure, and UV radiation. According to a report by the National Electrical Manufacturers Association (NEMA), cables that are rated for extreme temperatures can significantly enhance performance and longevity in adverse conditions. For instance, thermoplastic elastomer (TPE) insulation is recommended for applications where flexibility and resistance to extreme temperatures are required, with capabilities ranging from -40°C to 105°C, accommodating a variety of environments.

Humidity and moisture levels also play a vital role in cable selection. The American Wire Gauge (AWG) standards indicate that using cables with moisture-resistant coatings can prevent corrosion and short-circuiting, which are common in high-humidity areas. Chemical resistance is another critical aspect; cables designed with cross-linked polyethylene (XLPE) insulation can withstand exposure to various chemicals, making them suitable for industrial settings. Research from the International Electrotechnical Commission highlights the importance of using the right materials to ensure safety and reliability, with improper insulation potentially leading to failures that can disrupt operations and increase maintenance costs.

Cost vs. Quality: Analyzing Long-term Benefits of Investing in Quality Wire & Cable

When it comes to selecting the right wire and cable for your projects, the balance between cost and quality is crucial. Investing in high-quality products may seem like a significant upfront expense, but the long-term benefits often outweigh these initial costs. Quality wire and cable products typically offer better performance, durability, and reliability, which can save you money in the long run by reducing maintenance and replacement needs. For instance, low-quality cables might fail under strain, leading to disruptions and costly repairs that could have been avoided with a more robust solution.

As industries expand and evolve, such as the growing data centre landscape in the Middle East, the demand for reliable wire and cable becomes increasingly apparent. The investments being made in advanced infrastructure highlight the importance of choosing materials that can withstand the test of rapid technological advancement. Additionally, with the current economic climate and emerging tariffs impacting materials like copper, the relevance of choosing quality wiring is underscored. High-quality cables can help mitigate potential supply chain issues and ensure that your projects maintain operational continuity amidst fluctuating market conditions.

Related Posts

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

How to Choose the Right Woven Wire for Your Project Needs

-

How to Choose the Right Metal Screen for Your Project

-

Exploring the Benefits of Screen Mesh in Modern Home Renovations