10 Essential Tips for Choosing the Right Aluminum Mesh for Your Project?

Choosing the right aluminum mesh for your project can greatly impact its success. Industry expert John Smith once said, "The right mesh can make or break a project." This highlights the importance of understanding what to look for. Various factors set apart one aluminum mesh from another, such as size, material, and intended use.

Selecting aluminum mesh is not as straightforward as it seems. Many overlook crucial elements, leading to unsatisfactory results. Consider the type of project. Are you using it for safety, decor, or utility? Each requires distinct specifications. Not giving these details enough thought may lead to difficulties later.

Quality is key when it comes to aluminum mesh. A lesser quality mesh might save you money upfront but cost you more in the long run. Durability and strength should always be evaluated. Without these traits, your project may face premature failure. Thorough research and careful consideration are essential.

Understanding the Different Types of Aluminum Mesh Available

When choosing aluminum mesh for a project, understanding the different types is crucial. Aluminum meshes come in various styles, each catering to specific applications. The three common types include woven mesh, expanded mesh, and perforated sheets.

Woven aluminum mesh is often used for filtration due to its tight weave. Expanded mesh offers durability and strength, perfect for both fencing and architectural purposes. Perforated sheets provide airflow while maintaining structural integrity, making them ideal for applications like soundproofing.

Tip: Always consider the mesh opening size. Smaller openings are better for filtering, while larger openings let more airflow. According to recent industry reports, projects that prioritize mesh selection report a 30% increase in efficiency and effectiveness.

Another point to reflect on is the aluminum grade. Not all aluminum is created equal. For example, 6061 alloy is known for its balance of weldability and strength. This choice may impact how well the mesh performs in various environmental conditions.

Tip: Evaluate corrosion resistance when selecting aluminum mesh. Investing time in this aspect could save future maintenance costs. Industry data shows that 40% of mesh failures occur due to corrosion-related issues.

Factors to Consider When Assessing Mesh Size and Opening

When assessing mesh size and opening, the first thing to consider is the intended use. Different projects demand different specifications. For instance, if you’re working on a decorative fence, a larger mesh might be acceptable. However, if the project involves insect screening, finer mesh is critical. The size of the opening directly influences the functionality of the mesh. Larger openings may let in unwanted pests or particles.

It’s also important to think about the materials you will be using alongside the mesh. Aluminum is lightweight but less durable than other metals. Pairing it with the right frame can enhance the structure's strength. Remember that mesh size impacts airflow and visibility too. Small openings can restrict airflow, creating potential issues in ventilation.

Sometimes, the ideal choice may not be apparent. You might find that the most affordable option doesn’t always serve your needs effectively. Experimenting with varying sizes could yield surprising insights. Take your time to assess all options thoroughly. An uninformed choice can lead to costly mistakes in the long run. Reflecting on the project requirements will guide you toward the best aluminum mesh.

Evaluating Durability and Corrosion Resistance in Aluminum Mesh

When selecting aluminum mesh, durability and corrosion resistance are critical factors. Aluminum mesh is often exposed to various environmental conditions. Therefore, understanding how these factors impact performance is essential. Look closely at the aluminum alloy used. Different alloys offer varied levels of strength and corrosion resistance.

Consider the mesh's finish. Anodized finishes can enhance protection against corrosion. However, not all finishes are equal. Some may wear away faster under harsh conditions. It's also important to examine the wire diameter. Thicker wires tend to withstand heavier loads and resist bending over time.

Pitting and oxidation can be common issues. Regular inspections can help identify these problems early. Corrosive environments, such as coastal areas, may necessitate additional protective measures. It's worthwhile to remember that even high-quality mesh may require occasional maintenance. Balancing cost with quality can also be tricky. Sometimes, cheaper options may lead to more problems later on, affecting overall project success.

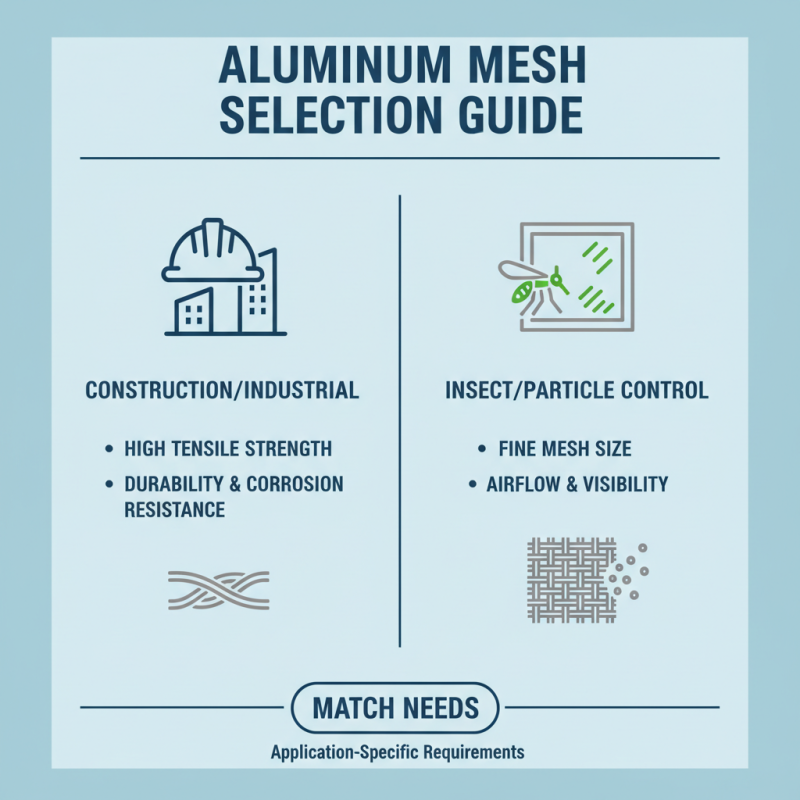

Examining Application-Specific Requirements for Aluminum Mesh

When selecting aluminum mesh for your project, understanding application-specific requirements is crucial. Different projects have distinct needs. For instance, a mesh used in construction may require high tensile strength. On the other hand, mesh for insect control must prioritize small openings. Matching these needs can be tricky.

Consider factors like corrosion resistance and weight. If you're creating a frame for outdoor use, choose a mesh that withstands the elements. Lightweight aluminum is easy to handle but may not hold up under stress. Test samples in real conditions. This helps avoid installation issues later on.

Another key aspect is the aesthetics of the mesh. Colors and finishes can enhance visual appeal. But, remember that functionality should never be compromised for looks. Always seek a balance. Don’t rush the selection process; take your time to reflect on your project's unique demands. Working through these considerations will lead to better choices.

Budgeting for Quality: Cost Considerations in Aluminum Mesh Selection

When budgeting for aluminum mesh, quality matters. High-quality mesh ensures durability and performance. However, it often comes with a higher price tag. Consider how long you need it to last. Investing more upfront can save you money in the long run.

Choosing the right mesh involves understanding your project needs. Is it for safety, decoration, or functional screening? Each requirement influences your choice and costs. For example, if you need a mesh for an outdoor project, it should withstand weather elements.

Tip: Always compare prices from multiple suppliers. This helps to identify reasonable options. Look for certifications that verify quality. They might cost more, but they often offer peace of mind. Reflect on the balance between budget and essential features. Quality shouldn't be overlooked for savings.

Related Posts

-

What is Aluminum Woven Wire Mesh and Its Applications in Various Industries

-

How to Choose the Right Metal Screen for Your Project

-

Why Choose Cable Mesh for Your Project Needs?

-

How to Choose the Best Wire Mesh for Your Home and Garden Projects

-

How to Choose the Best Woven Mesh for Your Projects?

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China