10 Essential Tips for Choosing the Right Metal Wire Mesh for Your Project

When embarking on a project that requires the use of metal wire mesh, selecting the right type can significantly influence the overall success and functionality of your work. Metal wire mesh is available in a vast array of materials, designs, and specifications, making the decision process both exciting and daunting. The right choice can enhance strength, durability, and aesthetics, while the wrong one might lead to unexpected complications or project failures.

In this guide, we will explore 10 essential tips designed to assist you in navigating the complexities of choosing the perfect metal wire mesh. From understanding different materials, such as stainless steel and galvanized wire, to determining the appropriate mesh size and pattern for your specific application, each aspect plays a crucial role in ensuring that your project meets its intended goals. Whether you are involved in architectural design, safety fencing, or artistic installations, making an informed choice about metal wire mesh will ultimately pay dividends in both performance and longevity.

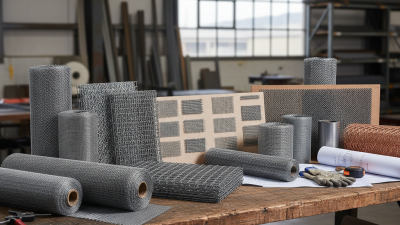

Understanding Different Types of Metal Wire Mesh Available on the Market

When selecting metal wire mesh for your project, it's crucial to understand the various types available on the market, as each serves distinct purposes. The most common types include

welded wire mesh,

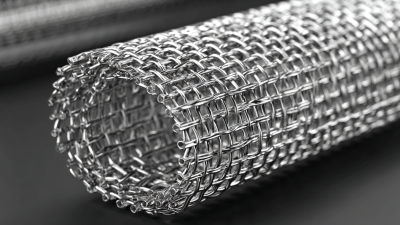

woven wire mesh, and

expanded metal mesh.

Welded wire mesh is popular for its strength and durability, often used in construction and agricultural applications. Its rigid design provides stability, making it ideal for fencing and reinforcing concrete structures.

Woven wire mesh, on the other hand, is created by interlacing strands of wire, offering flexibility and versatility. This type is frequently used for filtration and separation tasks, as well as in architectural designs where aesthetic appeal is also essential.

Expanded metal mesh is unique due to its manufacturing process, which involves slitting and stretching a sheet of metal to create a lattice pattern. This results in a lightweight yet sturdy material that's commonly used in walkways, security applications, and as a decorative element.

Understanding these types will significantly aid in choosing the right mesh for your specific needs. Evaluating the project requirements, such as load-bearing capacity, environmental factors, and intended use, will guide you toward the most appropriate metal wire mesh option.

Key Factors to Consider When Selecting Metal Wire Mesh for Your Needs

When selecting metal wire mesh for your project, understanding the key factors is essential to ensure you choose the right material for your needs. One of the primary considerations is the wire gauge, which affects both the strength and flexibility of the mesh. Thicker wires generally provide sturdier construction, making them ideal for heavy-duty applications, while thinner wires may suffice for decorative or lightweight uses.

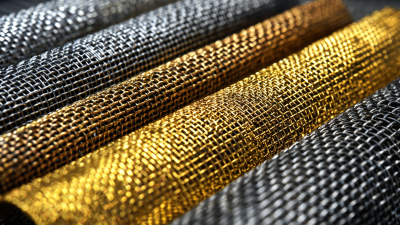

Another vital aspect is the type of material used in the mesh, such as stainless steel, galvanized steel, or aluminum. Each material has its unique properties, including corrosion resistance and weight. For instance, stainless steel is highly resistant to rust and is perfect for outdoor applications, whereas galvanized steel is cost-effective and great for general purposes.

Lastly, pay attention to the size of the mesh openings. This will vary based on the specific requirements of your project. Small openings are suitable for filtering applications, while larger openings might be better for ventilation. Overall, considering these tips will guide you in selecting the most suitable metal wire mesh that meets your project's demands.

Evaluating Wire Diameter and Mesh Size for Optimal Performance

When selecting metal wire mesh for your project, understanding wire diameter and mesh size is crucial for achieving optimal performance.

The wire diameter, measured in gauges, significantly influences the strength, flexibility, and overall applications of the mesh.

For instance, a thicker wire gauge, such as 10 (approximately 0.135 inches), is ideal for heavy-duty applications like industrial fencing and architectural elements, providing enhanced durability and resistance to wear.

Conversely, a thinner wire size, such as 20 gauge (approximately 0.032 inches), is preferable for lighter applications, including filtration systems and decorative features.

Mesh size, defined by the number of openings per linear inch, also plays a vital role in determining the functionality of the wire mesh.

According to a report by the Wire Mesh Manufacturers Institute (WMMI), a finer mesh, such as 1/4" openings, is commonly utilized in applications requiring fine filtration, while larger openings like 2" are suitable for ventilation and drainage needs.

When selecting your wire mesh, consider the specific needs of your project.

Tip: Always match wire diameter and mesh size to the environmental factors and mechanical stresses they will face.

If your project involves exposure to corrosives or harsh weather, opt for stainless steel options to enhance longevity.

Another important consideration is the project's aesthetic appeal—choose a mesh that complements the overall design.

The right balance of diameter and mesh size ensures not only functionality but also the visual integrity of your application.

Assessing Material Properties and Coatings for Durability

When selecting metal wire mesh for your project, assessing the material properties is crucial for ensuring durability and functionality. Different types of metals, such as stainless steel, galvanized steel, and aluminum, offer varying degrees of resistance to corrosion, strength, and flexibility. For instance, stainless steel is known for its excellent resistance to rust and harsh environmental conditions, making it a suitable choice for outdoor applications.

In contrast, galvanized steel provides a protective zinc coating, enhancing durability while remaining cost-effective for less demanding environments.

Coatings also play a significant role in the longevity of metal wire mesh. Various coatings, such as polymer or powder coatings, can add an extra layer of protection against the elements, reducing wear and tear over time. When selecting wire mesh, consider the specific environment it will be exposed to—humidity, chemicals, and temperature fluctuations can all impact the effectiveness of the coating. Ensuring that both the metal and its coating are suited to the project’s conditions will contribute to the overall success and durability of your installation.

Budgeting and Sourcing: Finding the Right Supplier for Wire Mesh Projects

When embarking on a wire mesh project, budgeting and sourcing from the right supplier are critical components that can significantly influence the success of your venture. A recent analysis of wire mesh fencing manufacturing costs highlights the importance of understanding project requirements and associated expenses. This insight can aid businesses in crafting a comprehensive budget that accommodates all facets of the project from initial setup to production.

To optimize your selection process, here are a few essential tips. First, evaluate potential suppliers based on their industry reputation and customer reviews. This groundwork ensures you collaborate with reliable partners. Second, consider the material quality and variety offered by suppliers. A provider that stocks a diverse range of metal wire mesh types will give you flexibility to meet your specific project requirements. Third, don’t overlook pricing; ensure you receive detailed quotes that break down costs to help you make an informed decision within your budget constraints.

By carefully considering these factors, you can effectively navigate the sourcing process and find the ideal metal wire mesh for your needs while maintaining financial viability.

Related Posts

-

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

How to Choose the Best Wire Mesh Products for Your Project Needs

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data