How to Choose the Right Woven Wire for Your Project Needs

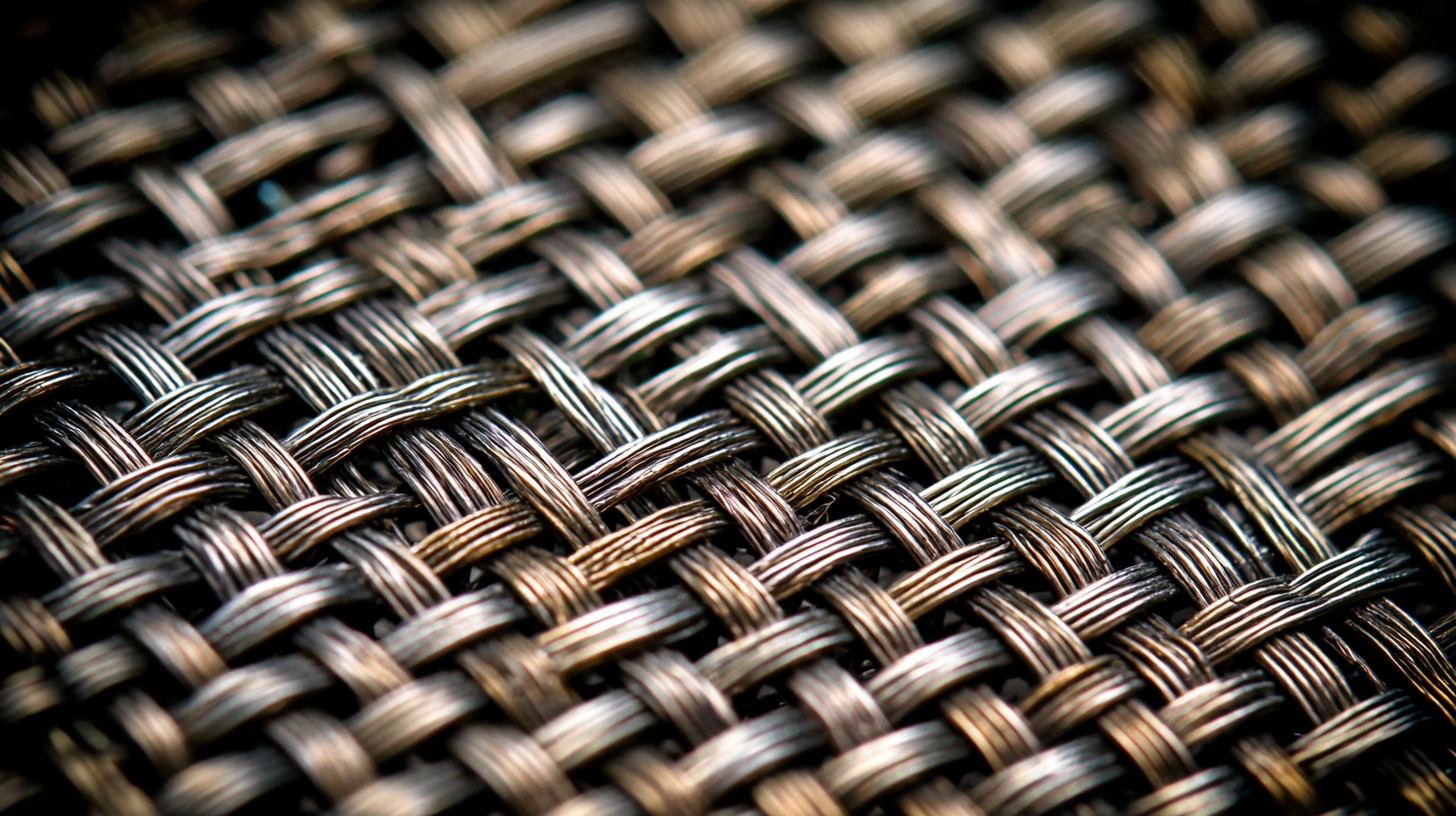

When embarking on a project that requires durable and versatile materials, understanding how to choose the right woven wire is crucial. Woven wire, with its intricate patterns and robust construction, provides a wide array of applications, from fencing and landscaping to industrial use and architecture. The selection process can be overwhelming due to the variety of wire types, mesh sizes, and materials available on the market.

This guide aims to simplify that decision-making by exploring key factors that will help you assess your project needs and understand the specific features of woven wire that will best suit your requirements. By considering aspects such as strength, flexibility, and corrosion resistance, you can ensure that your project not only meets aesthetic demands but also achieves practical functionality.

Let’s delve into the essential criteria that will enable you to choose the ideal woven wire for your upcoming endeavor.

Factors to Consider When Selecting Woven Wire for Different Applications

When selecting woven wire for different applications, several key factors come into play. First, the intended use of the woven wire should be evaluated. For instance, in the development of smart fabrics that incorporate conductive elements, the wire must not only provide strength but also facilitate the embedded electronics required for sensor detection. The performance characteristics, such as flexibility and conductivity, are crucial, particularly in wearable technology where user comfort and efficiency are paramount.

Another important factor is the material composition of the woven wire. Recent advancements have shown that using wire meshes made from glass fiber and steel can enhance energy absorption in composites, making them suitable for impact load-bearing applications. Additionally, understanding the performance of materials under different load conditions, such as projectile versus shock loadings, can inform the selection process for applications requiring robust mechanical properties. Therefore, analyzing the interplay of material properties, application requirements, and the specific environmental conditions will lead to the optimal choice of woven wire for any project.

Understanding Wire Material Types and Their Benefits for Your Project

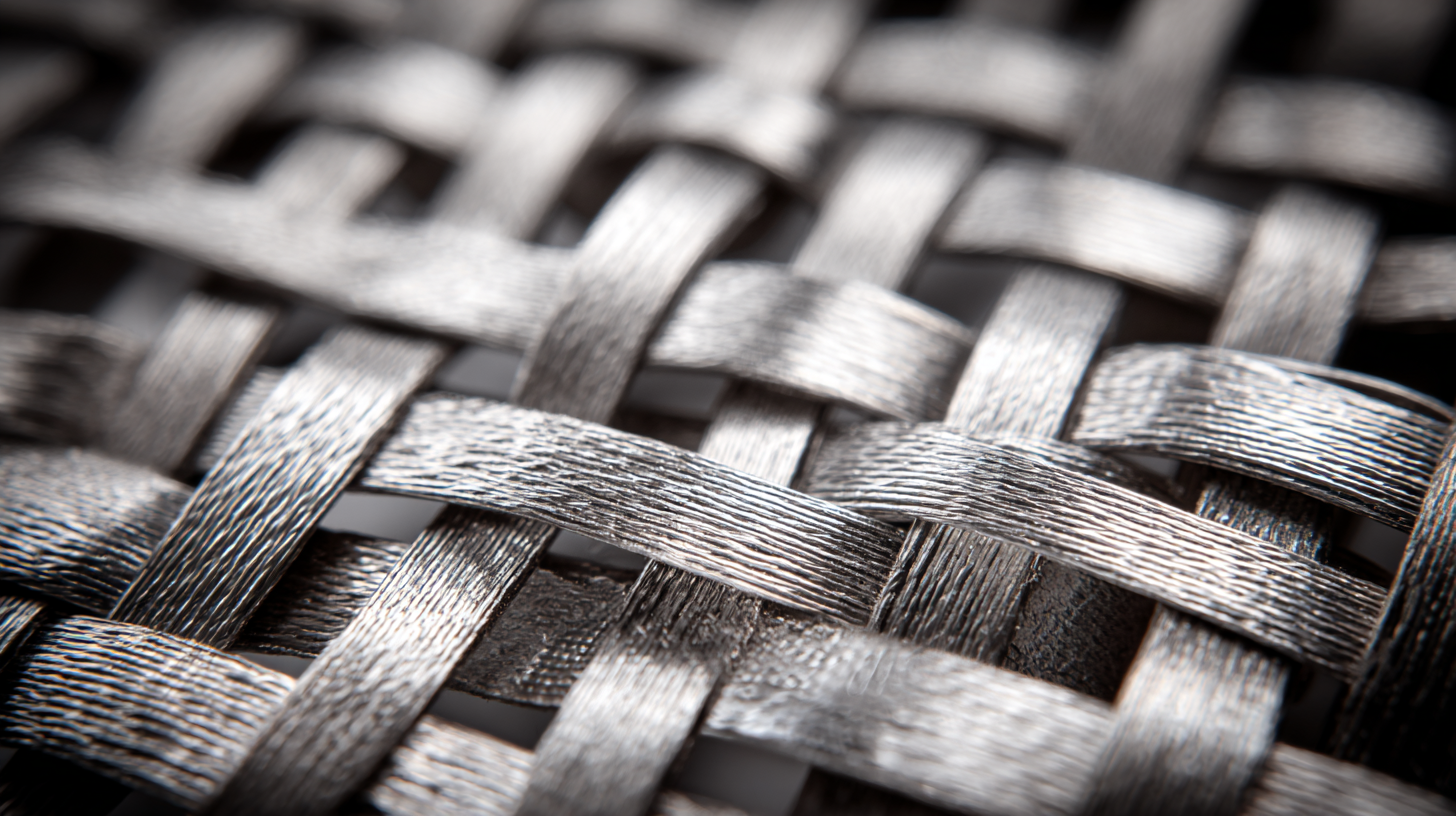

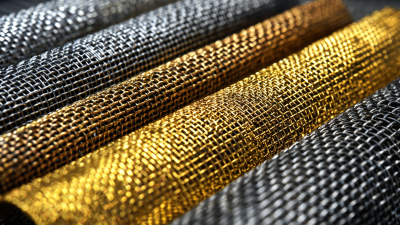

When it comes to choosing the right woven wire for your project, understanding the different types of wire materials is crucial. Common options include stainless steel, galvanized steel, and coated wire, each offering unique advantages depending on your requirements.

Stainless steel is renowned for its corrosion resistance and durability, making it an ideal choice for outdoor applications. Its aesthetic appeal also makes it suitable for decorative purposes, ensuring that functionality does not compromise style.

Stainless steel is renowned for its corrosion resistance and durability, making it an ideal choice for outdoor applications. Its aesthetic appeal also makes it suitable for decorative purposes, ensuring that functionality does not compromise style.

Galvanized steel, on the other hand, is coated with a layer of zinc, which provides an additional barrier against rust. This makes it a more cost-effective option for projects where exposure to the elements is a concern, yet long-term durability is still desired. Coated wires, available in various colors and materials, provide extra protection and can enhance the visual aspect of a project. They are particularly useful in residential settings, where blending into landscaping is important. By weighing the benefits of each material type, you can select a woven wire that not only meets your project needs but also aligns with your budget and aesthetic preferences.

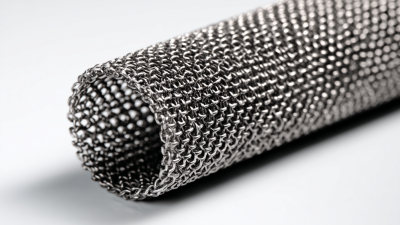

Sizing and Gauge: How to Determine the Right Thickness for Your Needs

When choosing the right woven wire for your project needs, determining the correct sizing and gauge is crucial for ensuring functionality and durability. The thickness of the wire, usually measured in gauge, plays a significant role in the wire's strength and resistance to various environmental factors. A lower gauge number indicates a thicker wire, which can offer more strength for heavy-duty applications, while a higher gauge signifies a thinner wire, better suited for lighter tasks. Evaluating the specific requirements of your project will help you select the appropriate gauge for optimal results.

**Tips:** Always consider the load and stress the wire will be subjected to. For fencing projects, a lower gauge will provide improved security and longevity. For crafting or garden projects, higher gauge options may be more cost-effective and visually appealing. Additionally, remember that environmental conditions, such as exposure to moisture or salt, can influence the longevity of the wire, so choose materials that withstand local conditions effectively.

Woven Wire Gauge Comparison

This chart illustrates the comparison of different wire gauges commonly used in woven wire projects. The wire gauge affects the thickness and strength of the wire, which is crucial for determining the suitability for various applications.

Common Mistakes to Avoid When Choosing Woven Wire

When selecting woven wire for your project, avoiding common mistakes can significantly enhance your outcome. One prevalent error is neglecting to assess the specific requirements of your project. Different applications demand different types of woven wire, whether it's for construction, fencing, or decorative purposes. Failing to match the wire specifications with project needs can lead to unsatisfactory results or even structural failures.

Another frequent mistake is disregarding the environmental factors the wire will face. Factors such as exposure to moisture, chemicals, and temperature fluctuations can impact the wire's longevity and performance. Choosing a wire that is not corrosion-resistant for outdoor projects or one that cannot withstand high temperatures can result in premature degradation. Ensuring you understand the conditions in which the wire will be utilized is crucial for making an informed choice that ensures durability and effectiveness in your project.

Comparative Analysis of Woven Wire vs. Other Fencing Solutions

When selecting fencing materials for your project, woven wire fencing stands out due to its unique combination of strength, flexibility, and versatility. Unlike other fencing solutions, such as chain-link or wooden fences, woven wire can adapt to various terrains, making it ideal for everything from agricultural settings to residential gardens. Its design allows for an open visibility that is advantageous for both aesthetic purposes and safety, providing a secure barrier without completely obstructing the view.

On the other hand, while woven wire offers numerous benefits, it is essential to consider the limitations compared to alternatives like vinyl or electric fencing. Vinyl fencing, for example, is virtually maintenance-free and offers a solid barrier, which may be preferred in areas where privacy is a concern. Electric fencing, on the other hand, provides a strong deterrent for potential intruders and is particularly effective for livestock management. Each type of fencing has its strengths, making it crucial to evaluate the specific needs of your project against the characteristics of woven wire and other solutions.

Related Posts

-

How to Choose the Right Metal Screen for Your Project

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

How to Choose the Right Wire and Cable for Your Electrical Projects

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right Stainless Mesh for Your Specific Applications