How to Choose the Right Wire Products for Your Project Needs

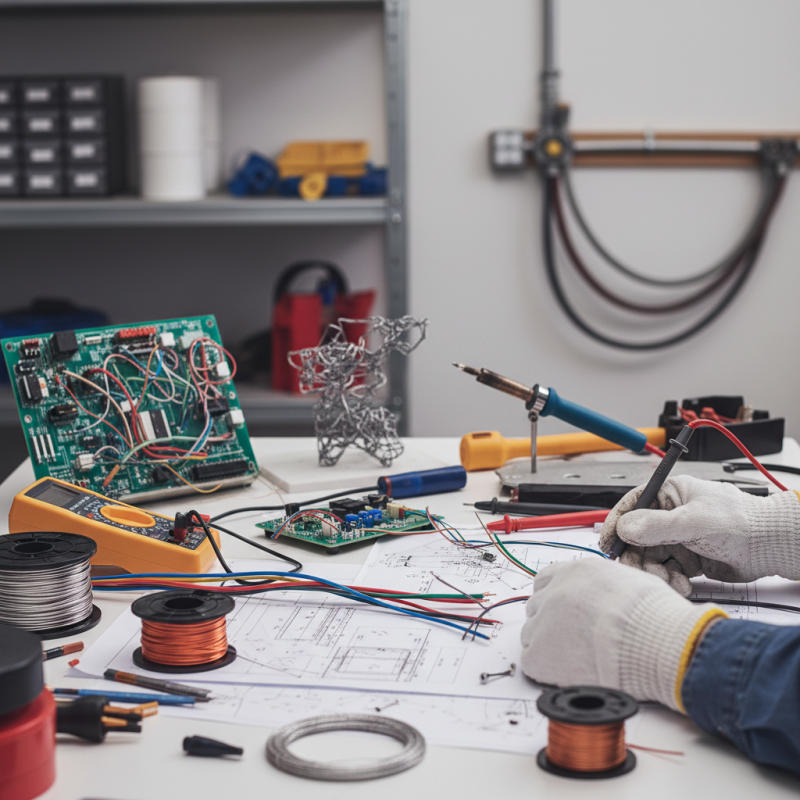

When embarking on a project that requires electrical or structural connectivity, selecting the right wire products is crucial for ensuring both safety and efficiency. Wire products come in various types, sizes, and materials, each designed to meet specific requirements and conditions. Whether you are working on home renovations, automotive repairs, or crafting electronic devices, understanding the myriad wire options available can significantly impact the success of your project.

In order to make an informed decision, it is essential to consider several factors such as the application's voltage requirements, environmental conditions, and compatibility with other materials. Different wire products also adhere to unique standards and specifications, which can further complicate the selection process. By navigating through these elements with care, project managers and DIY enthusiasts alike can choose wire products that not only meet their immediate needs but also ensure long-term reliability and performance.

Ultimately, the right wire products will provide the backbone of any project, facilitating connectivity and efficiency. This guide aims to assist you in understanding the key aspects to consider, enabling you to select the best wire solutions tailored to your project requirements.

Understanding Different Types of Wire Products Available in the Market

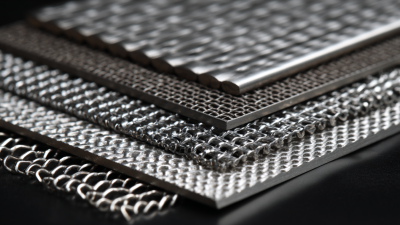

When embarking on a project that requires wire products, it is essential to understand the variety of options available in the market. Wire products can generally be categorized into several types, including copper, aluminum, stainless steel, and specialty alloys. According to the International Wire & Cable Industry Association, the global wire and cable market was valued at approximately $180 billion in 2020 and is projected to grow significantly due to increasing demand across various sectors, including construction, automotive, and telecommunications.

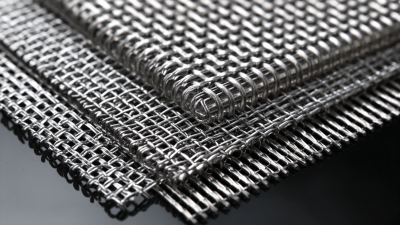

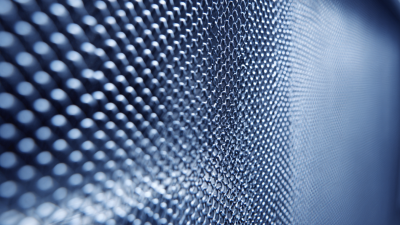

Copper wire is widely recognized for its excellent electrical conductivity, making it a preferred choice for electrical applications. Aluminums, while lighter and often more cost-effective, may not match copper's conductivity but are ideal for power distribution where weight is a concern. Stainless steel wire, on the other hand, offers superior corrosion resistance and is perfect for outdoor or marine environments. A report by MarketsandMarkets suggests that the stainless steel wire market alone is expected to reach $4.5 billion by 2026, reflecting diverse industrial needs.

It is also crucial to consider the specific requirements of your project, such as tensile strength, flexibility, and insulation needs. Specialty wire products, like those with coatings or added functionalities, play pivotal roles in applications ranging from aerospace to medical devices. Understanding these types enables project managers and engineers to select the most appropriate wire products, ultimately enhancing performance and durability in their projects.

Assessing Project Requirements for Wire Product Selection

When selecting wire products for a project, it is crucial to first assess the specific requirements of the task at hand. Understanding the intended use of the wire is fundamental—whether it is for electrical applications, structural support, or decorative purposes. This knowledge will guide you in determining the appropriate materials, sizes, and types of wires needed. Additionally, consider factors such as environmental conditions, load capacities, and the duration for which the wire products will be in use.

Another vital aspect of assessing project requirements is identifying the necessary standards and regulations that may apply to your wire selection. Different industries have specific compliance needs based on safety and durability, which can dictate the type of wire products you can use. Moreover, evaluating the installation process may impact your choice, as some wire products are designed for ease of use while others may require specialized tools and techniques. By carefully analyzing these factors, you can make informed decisions that align with your project’s objectives and ensure successful outcomes.

Wire Products Selection for Project Needs

This bar chart illustrates the suitability of various wire products for project needs, based on a scale from 0 to 100. The higher the score, the more suitable the product is deemed for typical project requirements.

Key Factors to Consider When Choosing Wire Products

When selecting wire products for any project, several key factors must be taken into account to ensure optimal performance and safety. First and foremost, understanding the specific requirements of your project is crucial. For instance, will the wire be used in residential, commercial, or industrial applications? According to a recent industry report, approximately 40% of wire failures can be attributed to mismatched specifications and improper material selections. Therefore, considering the wire's gauge, insulation type, and conductor material is essential.

Another critical element to consider is the environmental conditions where the wire will be installed. Exposure to moisture, heat, or chemicals can significantly impact the wire's longevity and reliability. A survey by the Association of Electrical and Electronic Manufacturers indicated that nearly 30% of wire product issues stem from inadequate environmental adaptations. Selecting materials that offer corrosion resistance and thermal stability can mitigate these risks.

**Tips:** Always verify the wire's load rating and ensure it complies with local electrical codes to maintain safety standards. Additionally, consulting with experienced suppliers can provide valuable insights into the latest wire technologies that may enhance your project's effectiveness. Lastly, always ensure proper installation techniques are employed to avoid future complications.

Comparing Material Properties of Various Wire Products

When selecting wire products for your project, understanding the material properties is essential. Wire is typically made from a variety of materials, including stainless steel, copper, and aluminum, each offering distinct advantages depending on the application. For instance, stainless steel is renowned for its corrosion resistance and strength, making it an ideal choice for outdoor and marine environments. Copper, while highly conductive, is more prone to oxidation, limiting its use in certain applications unless properly coated or treated.

Tips: Always consider the environmental conditions your project will face. For high-wear or corrosive environments, opt for materials with enhanced corrosion resistance. Similarly, for electrical projects, choose wire products with optimal conductivity to ensure efficient performance.

Aluminum wire is lightweight and resistant to corrosion, which is advantageous in applications where weight is a factor. However, it has lower tensile strength compared to stainless steel and copper and may require careful handling. When comparing these materials, balance factors like strength, weight, corrosion resistance, and conductivity in relation to your specific project needs to make an informed decision.

Tips: Conduct a small test if feasible. This can help gauge how a particular wire material performs under your project’s specific conditions.

Best Practices for Sourcing and Purchasing Wire Products

When sourcing wire products for your project, it is essential to begin with a clear understanding of your requirements. This includes determining the specific type of wire needed based on your project's electrical or mechanical parameters, such as wire gauge, insulation type, and conductivity. By establishing these criteria early on, you can streamline the selection process and avoid potential issues later in the project.

Once your requirements are defined, prioritize sourcing from reputable suppliers who offer quality assurance and transparency in their manufacturing processes. Request detailed specifications and certifications to ensure the products meet industry standards. Additionally, consider using multiple suppliers to mitigate risks related to delays or product defects, allowing for a more resilient supply chain. Engaging directly with manufacturers can also provide insights into the materials and techniques used, ensuring that you make informed purchasing decisions that align with your project's goals.

Related Posts

-

How to Choose the Right Wire Products for Your Next Project

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

Understanding the Importance of Screen Mesh in Modern Home Ventilation Systems

-

10 Essential Tips for Choosing the Right Metal Wire Mesh for Your Project

-

Exploring the Versatility of Stainless Steel Mesh in Modern Applications