How to Choose the Right Wire Mesh Products for Your Project Needs

When embarking on a construction or manufacturing project, the selection of appropriate materials is crucial for ensuring durability, functionality, and safety. One such material that plays a vital role across various industries is wire mesh products. According to a report by MarketsandMarkets, the global wire mesh market is projected to reach USD 10.5 billion by 2025, growing at a CAGR of 6.8% from 2020. This significant growth underscores the importance of wire mesh in areas ranging from construction and agriculture to automotive and manufacturing sectors.

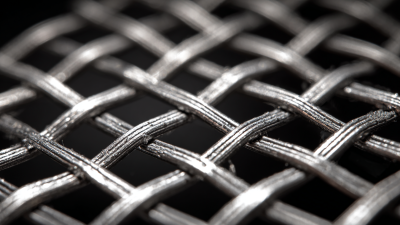

Choosing the right wire mesh products involves understanding not only the technical specifications but also how these products cater to specific project requirements. Factors such as material type, wire gauge, and mesh size must be carefully considered to ensure optimal performance. For instance, stainless steel wire mesh is often preferred for its corrosion resistance, while galvanized steel mesh is favored for its strength and cost-effectiveness. A report from Grand View Research highlights that the increasing demand for protective barriers and filtration systems is driving the growth in wire mesh applications, making informed selection even more pertinent to project success.

Factors to Consider When Selecting Wire Mesh Products for Your Project

When selecting wire mesh products for your project, several critical factors must be taken into account to ensure optimal results. One fundamental consideration is the type of material used in the wire mesh. Common materials include stainless steel, galvanized steel, and PVC-coated wire, each offering different benefits in terms of durability, resistance to corrosion, and overall strength. For example, galvanized steel is often preferred for outdoor applications due to its resistance to rust, while stainless steel is ideal for environments that require greater strength and longevity.

Another important factor to consider is the mesh size and aperture. The choice of wire diameter and opening size directly impacts the mesh's performance for specific applications, such as fencing, filtration, or reinforcement. According to a recent report by IMARC Group, understanding these specifications is crucial for minimizing manufacturing costs while maximizing efficiency. Their analysis highlights that careful planning in the selection process can lead to significant savings, particularly when setting up a wire mesh fencing manufacturing plant. By meticulously assessing these elements, project managers can not only enhance the effectiveness of their projects but also align with industry standards and trends, ultimately leading to successful outcomes.

Wire Mesh Product Selection Criteria

Different Types of Wire Mesh: Which is Best for Your Needs?

When selecting wire mesh products for your project, understanding the different types available is crucial to making an informed decision. One popular option is welded wire mesh, characterized by its durability and structural integrity. This type is ideal for applications requiring strength, such as fencing, concrete reinforcement, or safety barriers. The closely spaced intersections provide a robust structure, making it a reliable choice for heavy-duty projects.

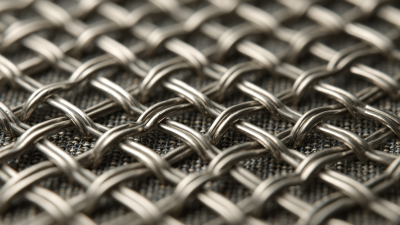

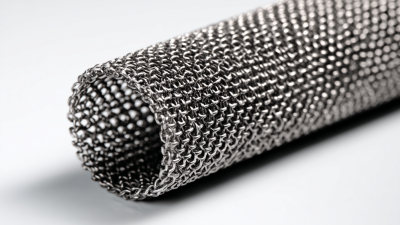

Another common type is knitted wire mesh, which offers flexibility and versatility. It is often used in industrial applications and filtration processes due to its ability to conform to various shapes and sizes. If you're looking for a solution that requires adaptability, knitted wire mesh could be the ideal fit. Conversely, if your project demands a lightweight option, expanded metal mesh is a suitable alternative. It provides excellent drainage and ventilation while maintaining strength, making it a great choice for architectural and design projects. Ultimately, your choice of wire mesh should align with the specific requirements and functionality needed for your project.

Another common type is knitted wire mesh, which offers flexibility and versatility. It is often used in industrial applications and filtration processes due to its ability to conform to various shapes and sizes. If you're looking for a solution that requires adaptability, knitted wire mesh could be the ideal fit. Conversely, if your project demands a lightweight option, expanded metal mesh is a suitable alternative. It provides excellent drainage and ventilation while maintaining strength, making it a great choice for architectural and design projects. Ultimately, your choice of wire mesh should align with the specific requirements and functionality needed for your project.

Understanding Wire Gauge and Its Impact on Project Durability

When selecting wire mesh products for your project, understanding wire gauge is crucial, as it directly affects the durability and suitability of the mesh for specific applications. Wire gauge refers to the thickness of the wire, which is measured using the American Wire Gauge (AWG) system. The lower the gauge number, the thicker the wire will be.

Thicker wires provide enhanced strength and durability, making them ideal for heavy-duty applications such as construction and industrial settings, where robust support is necessary to withstand external forces.

Thicker wires provide enhanced strength and durability, making them ideal for heavy-duty applications such as construction and industrial settings, where robust support is necessary to withstand external forces.

In contrast, thinner wire gauges are more flexible and lightweight, making them suitable for lighter applications such as fencing or decorative purposes. However, opting for a thinner gauge may compromise the overall structural integrity of the mesh under stress. Thus, it’s essential to evaluate the specific requirements of your project, including load-bearing capacities and environmental factors, to determine the appropriate wire gauge. By making an informed choice based on wire thickness, you can ensure the longevity and effectiveness of your wire mesh products, ultimately leading to the success of your project.

Applications of Wire Mesh in Various Industries and Projects

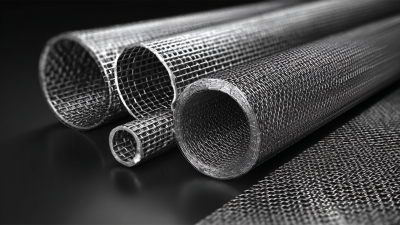

Wire mesh products are incredibly versatile and find applications across various industries, including construction, agriculture, and manufacturing. In construction, wire mesh serves as reinforcement for concrete structures, providing strength and durability. In the agricultural sector, it is commonly used for fencing, ensuring the safety of livestock and the security of crops against pests. Manufacturing industries utilize wire mesh for filtration systems, allowing for efficient separation of materials.

When selecting wire mesh for your project, consider these tips: First, assess the specific requirements of your project, including load-bearing needs and environmental conditions. Different materials, such as stainless steel or galvanized steel, offer unique properties suitable for various applications. Second, examine the wire mesh's openness or aperture size, as this affects airflow and material passage. Finally, ensure that the chosen wire mesh aligns with industry standards and regulations, which can vary based on location and intended use.

By evaluating these factors, you can make informed decisions that suit your project's unique requirements while ensuring optimal performance and longevity of the wire mesh products you select.

How to Choose the Right Wire Mesh Products for Your Project Needs

| Industry | Application | Wire Mesh Type | Material | Wire Diameter (mm) | Hole Size (mm) |

|---|---|---|---|---|---|

| Construction | Reinforcement | welded wire mesh | Steel | 3.0 | 25.0 |

| Agriculture | Fencing | chain link mesh | Galvanized Steel | 2.5 | 50.0 |

| Mining | Screening | woven wire mesh | Stainless Steel | 1.5 | 10.0 |

| Food Industry | Conveyor Belts | stainless steel wire mesh | 304 Stainless Steel | 2.0 | 15.0 |

| Automotive | Filters | fine mesh | Aluminum | 0.8 | 5.0 |

Key Suppliers and Manufacturers to Consider for Quality Wire Mesh Products

When selecting wire mesh products for various projects, it is essential to consider reputable suppliers and manufacturers. High-quality wire mesh is critical for performance and durability, whether used in construction, filtration, or fencing applications. Leading manufacturers often specialize in specific materials such as steel, aluminum, and stainless steel, each offering unique benefits. For instance, stainless steel mesh is recognized for its corrosion resistance, making it ideal for outdoor and industrial environments.

In the growing market for wire mesh products, several key players stand out due to their commitment to quality and innovation. Providers focusing on manufacturing advancements, such as the integration of data analysis technologies, can significantly impact efficiency and product reliability. Moreover, industry reports, such as those on the woven wire mesh belt conveyor market, highlight trends that inform buyers about emerging technologies and applications. It is crucial for project managers and engineers to stay updated on these insights to make informed purchasing decisions.

Related Posts

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

2025 Top 5 Fine Metal Mesh Products for Enhanced Performance and Durability

-

Top 10 Essential Tips for Choosing the Right Wire & Cable for Your Projects

-

How to Choose the Right Stainless Mesh for Your Specific Applications