How to Choose the Right Metal Screen for Your Project

When embarking on a construction or design project, selecting the appropriate metal screen is essential to ensure both functionality and aesthetics. According to a recent industry report by MarketsandMarkets, the global metal screen market is projected to reach $18 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth underscores the increasing demand for metal screens across various sectors, including architecture, interior design, and industrial applications. Factors such as durability, corrosion resistance, and design versatility play crucial roles in the decision-making process. Additionally, with innovative production techniques emerging, options such as perforated or expanded metal screens offer enhanced performance and visual appeal. Thus, understanding the specific requirements of your project is critical to choosing the right metal screen that meets both functional needs and design aspirations.

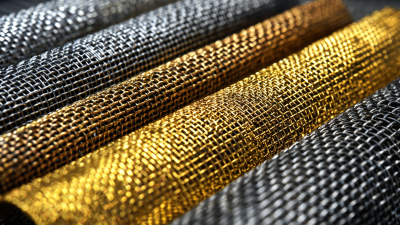

Understanding Different Types of Metal Screens for Various Applications

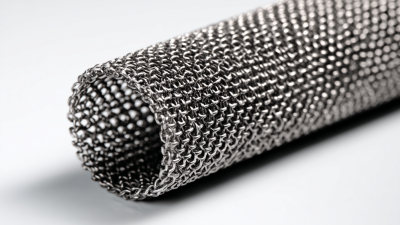

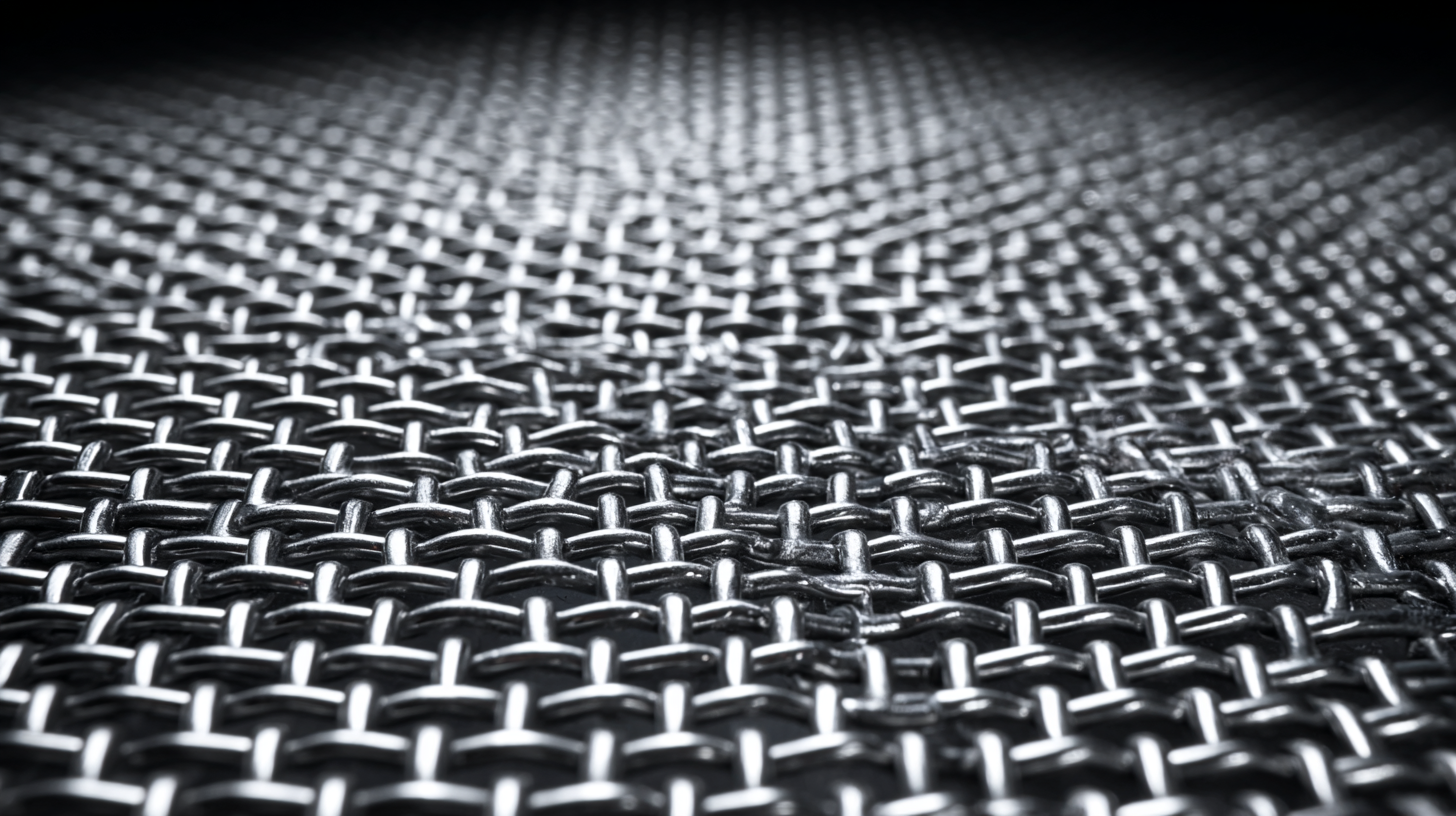

When selecting a metal screen for your project, it’s essential to understand the various types and their specific applications. Different materials—such as stainless steel, copper, and aluminum—offer unique properties that make them suitable for specific environments. For instance, stainless steel screens are renowned for their durability and resistance to corrosion, making them ideal for outdoor applications or areas exposed to harsh weather conditions. According to a report by the Industrial Metal Supply Company, approximately 70% of professionals in architecture and construction recommend stainless steel for facades and security screens, highlighting its versatility and reliability.

In contrast, aluminum screens are lightweight and easy to install, making them a popular choice for residential projects like window screens and patio enclosures. A recent survey found that around 40% of homeowners prefer aluminum for its aesthetic appeal and energy efficiency. Meanwhile, copper screens provide not just a stylish finish but also natural antimicrobial properties, making them suitable for healthcare settings. With the metal screening market projected to grow by 5.3% annually through 2025, understanding the nuances of each type allows stakeholders to make informed decisions that align with both function and design.

Key Factors to Consider When Selecting Metal Screen Materials

When selecting metal screen materials for your project, several key factors should guide your decision-making process. First, consider the environment where the screens will be installed. For outdoor applications, you might need corrosion-resistant materials such as stainless steel or aluminum, which can withstand exposure to moisture and harsh weather. In contrast, for indoor uses, carbon steel screens may be suitable, provided they are treated to prevent rust.

Another crucial aspect is the functionality of the metal screens. Think about the purpose they will serve—whether they provide privacy, security, or ventilation. For instance, if security is a priority, opt for a thicker gauge that offers greater durability against forced entry. Additionally, eye-catching designs and finishes can contribute to aesthetic appeal, so it’s wise to explore various styles that complement the surrounding decor. Ultimately, understanding these factors will help ensure you select a metal screen that not only meets your functional needs but also aligns with your project's vision.

How to Choose the Right Metal Screen for Your Project - Key Factors to Consider When Selecting Metal Screen Materials

| Material Type | Corrosion Resistance | Strength | Weight | Cost |

|---|---|---|---|---|

| Aluminum | High | Medium | Light | Medium |

| Stainless Steel | Very High | High | Medium | High |

| Mild Steel | Low | Medium | Heavy | Low |

| Copper | Medium | High | Medium | High |

| Brass | Medium | Medium | Medium | High |

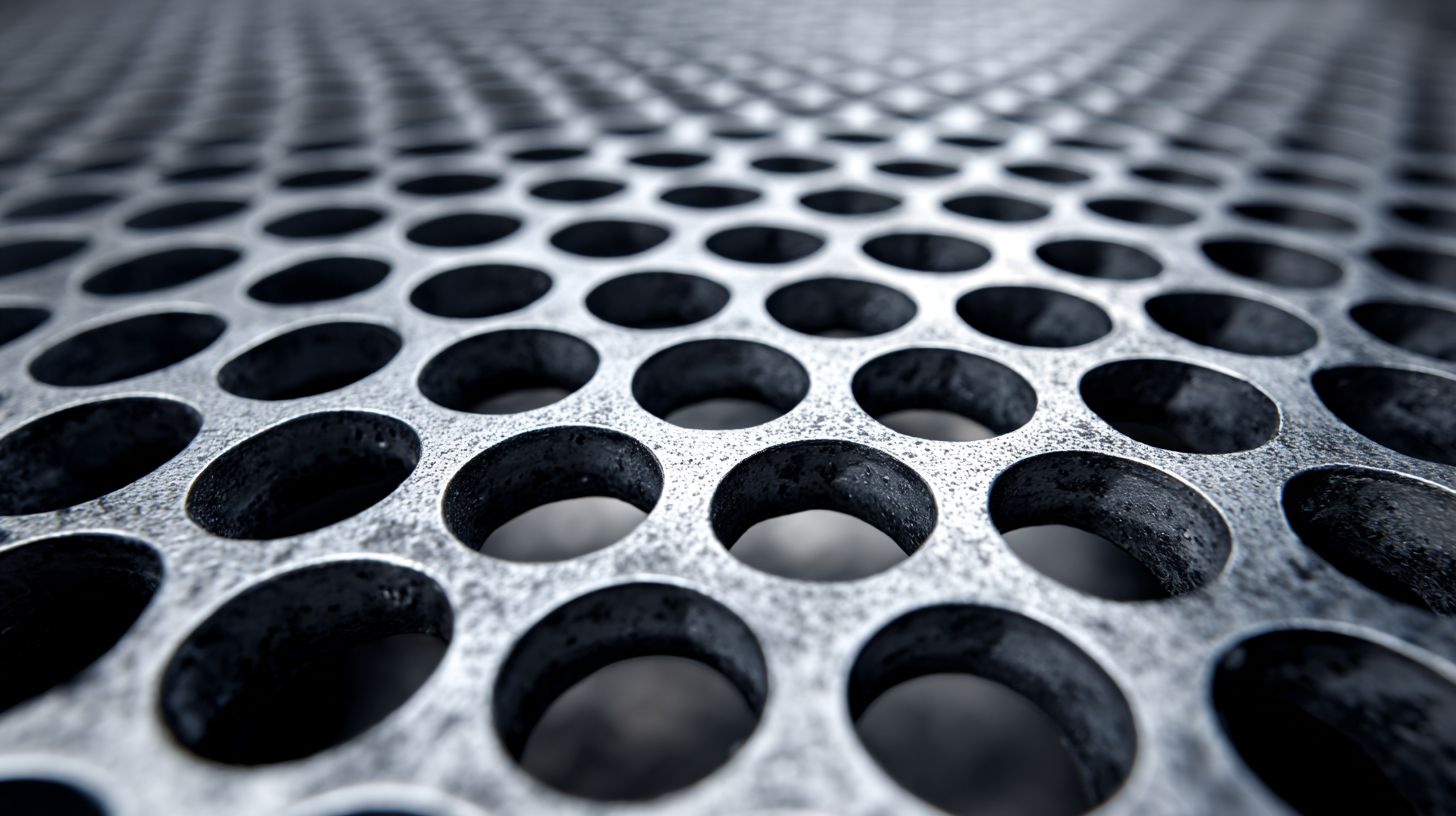

Comparative Analysis of Metal Screen Designs and Their Benefits

When selecting the right metal screen for your project, it is crucial to analyze the different designs available and their respective benefits. A comparative analysis of metal screen types reveals that non-uniform perforated screens outperform uniform ones in terms of daylighting effectiveness while maintaining similar perforation ratios. This characteristic can significantly enhance the visual comfort of indoor spaces, making them more conducive to various activities.

When selecting the right metal screen for your project, it is crucial to analyze the different designs available and their respective benefits. A comparative analysis of metal screen types reveals that non-uniform perforated screens outperform uniform ones in terms of daylighting effectiveness while maintaining similar perforation ratios. This characteristic can significantly enhance the visual comfort of indoor spaces, making them more conducive to various activities.

Tips: Consider using periphery-center or bottom-top patterned non-uniform screens to maximize natural light penetration without compromising on privacy. Additionally, evaluate how different materials and manufacturing techniques impact the screen's performance in your specific application.

Furthermore, integrating advanced materials such as metal-organic frameworks can improve electrical conductivity, allowing for innovative applications beyond traditional uses. During the evaluation process, it is essential to weigh the technical characteristics of each screen type against your project's specific needs, ensuring optimal functionality and aesthetic appeal.

Tips for Assessing Durability and Maintenance of Metal Screens

When selecting the right metal screen for your project, it's crucial to assess its durability and maintenance requirements. Durability is often influenced by the material composition of the screen, with options ranging from aluminum to steel alloys. Understanding the environment in which the screen will be used—whether it's exposed to harsh weather conditions or corrosive substances—will guide you in choosing a material that can withstand such challenges. Additionally, advancements in metal composite panels have led to enhanced performance, making them a viable option for long-term projects, particularly in sustainable construction.

Maintenance is another vital factor in your selection process. Metal screens require different maintenance levels depending on their coating and material type. Favoring finishes that resist corrosion and degradation can significantly reduce upkeep efforts. Trends in sustainable building materials also emphasize technological innovations that enhance the longevity of metal products, making them more appealing for environmentally conscious projects. By focusing on these elements, you can ensure that your metal screen not only meets aesthetic standards but also provides lasting performance and reduced maintenance costs.

Durability and Maintenance Assessment of Metal Screens

Cost-effective Strategies for Sourcing the Right Metal Screens

When sourcing metal screens for your project, it’s crucial to balance cost and quality, especially in a rapidly evolving market. A recent study highlights that optimizing production through AI technologies can yield significant cost-saving opportunities in various manufacturing sectors. By leveraging such innovations, businesses can not only reduce expenses but also enhance the quality of the materials they use. For example, implementing AI-driven analytics has been shown to improve decision-making processes in material sourcing, increasing overall project efficiency.

Tips: Consider utilizing AI-based tools to analyze potential suppliers and their offerings, this can streamline the selection process and highlight the best options based on predefined criteria of cost and durability. Furthermore, staying updated with emerging trends in sustainable materials can also provide insights into alternative metal screen options that may offer better performance at a similar price point.

Investing in comprehensive market reports can help you understand the latest advancements in metal screen production technologies. For instance, newer sustainable building materials are focusing on enhanced performance and innovative production methods, which can lead to long-term savings. Adopting such approaches not only meets current project requirements but also paves the way for sustainable practices in your business operations.