How to Choose the Right Metal Mesh for Your Industrial Applications

Selecting the appropriate metal mesh for industrial applications is crucial to ensuring optimal performance and efficiency in various processes. Metal mesh, known for its versatility and durability, serves multiple functions across industries, from filtration and sieving to reinforcement and shielding. With an array of materials, opening sizes, and weave patterns available, making an informed choice can significantly impact operational outcomes and product quality.

This guide delves into the essential factors to consider when choosing metal mesh, including material compatibility, application requirements, and environmental conditions. By understanding these elements, businesses can tailor their metal mesh selections to meet specific needs, ultimately enhancing their operational capabilities and achieving desired results.

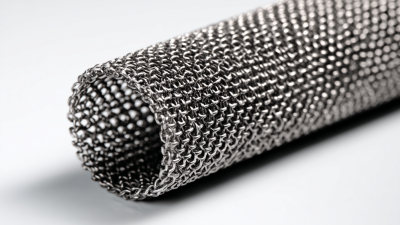

Understanding Different Types of Metal Mesh: Properties and Applications

When selecting the right metal mesh for industrial applications, it is crucial to understand the diverse range of metal mesh types and their unique properties. Metal meshes, typically made from stainless steel, aluminum, or other alloys, offer different levels of strength, durability, and corrosion resistance. For instance, stainless steel mesh is renowned for its resistance to oxidation and rust, making it ideal for applications in food processing and pharmaceuticals. In contrast, aluminum meshes are lightweight and exhibit excellent thermal conductivity, which can be advantageous in electronic applications.

Recent studies emphasize the importance of metal-organic frameworks (MOFs) in enhancing material properties for various applications, showing that combining metal nodes with organic components can lead to millions of distinct configurations. With over 90,000 known MOFs, their versatility in applications—ranging from batteries to construction—demonstrates a growing need for advanced material selection across industries.

Understanding the specific properties and applications of various metal meshes can aid industries in optimizing structural integrity and efficiency, paving the way for innovations in manufacturing processes and product development.

Key Considerations for Metal Mesh Selection in Industrial Environments

When selecting the right metal mesh for industrial applications, several key considerations play a crucial role in ensuring optimal performance and longevity. The type of material used in the mesh, such as stainless steel, aluminum, or titanium, will significantly impact its durability and resistance to corrosion. Additionally, the mesh's opening size and thickness are vital for achieving the required balance between strength and filtration capabilities. For environments that involve high levels of stress or extreme temperatures, these factors become even more critical.

Tips for metal mesh selection include assessing the specific application requirements before making a decision. Evaluate the environmental conditions—such as exposure to chemicals or fluctuating temperatures—to choose a mesh that can withstand those challenges. Furthermore, consider the intended use of the mesh, whether it’s for filtration, safety, or support, as different applications demand varying features.

It's also advisable to consult with industry experts or manufacturers for tailored solutions. They can provide insights into the latest technologies and innovations in metal mesh products, ensuring that your choice is not only functional but also cost-effective. Investing time in the selection process will ultimately lead to enhanced operational efficiency and reduced maintenance costs in the long run.

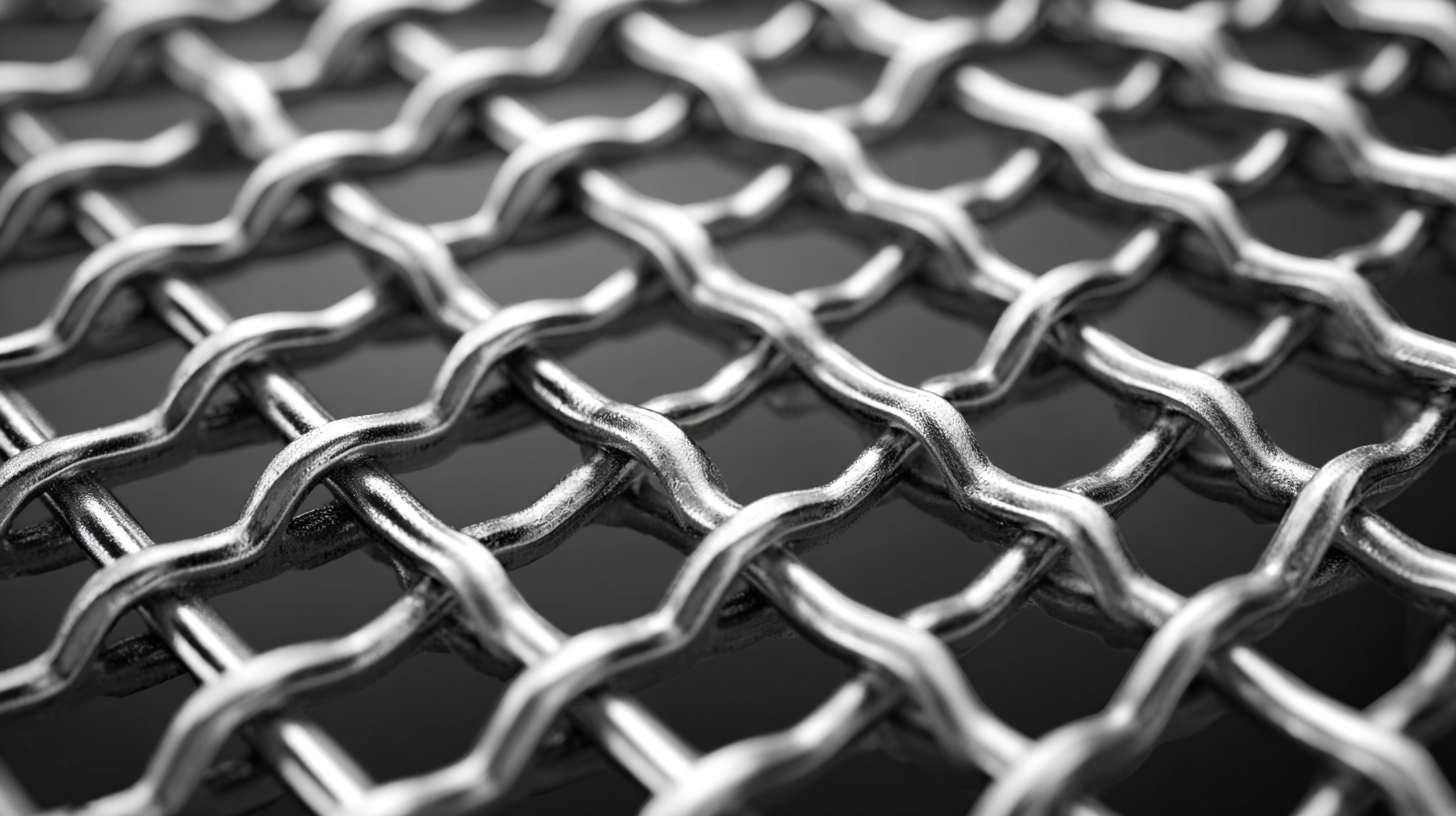

Analyzing Mesh Size and Opening Percentage: Impact on Performance

When choosing the right metal mesh for industrial applications, understanding the impact of mesh size and opening percentage on performance is crucial. Recent studies highlight that the design parameters of mesh structures can significantly influence operational efficiency. For instance, research comparing various nebulizer designs demonstrated that smaller particle sizes enhance aerosol delivery performance, indicating that a finely-tuned mesh size is essential in applications requiring precise material flow or filtration.

Furthermore, the wicking dynamics and pore structure analysis of different porous surfaces show that both metal foams and meshes can have varied performance outcomes based on their architecture. The integration of specific mesh sizes can optimize flow rates and enhance overall usability in systems such as cooling devices or aerosol generators. Reports suggest that adjusting the mesh size could lead to an increase in efficiency by up to 30%, underscoring the necessity of selecting the appropriate parameters for optimal performance in industrial settings.

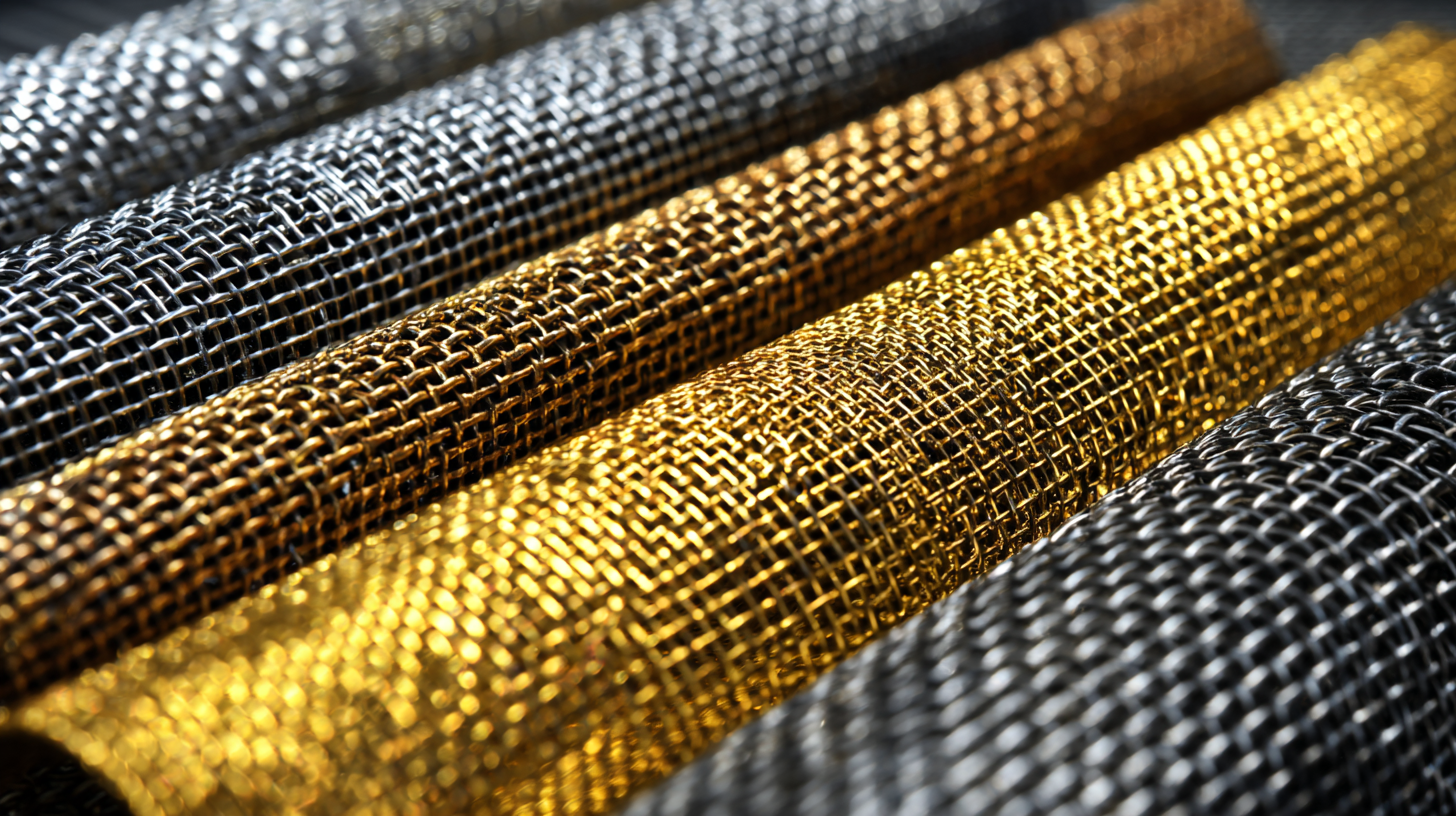

Evaluating Material Choices: Stainless Steel vs. Carbon Steel Mesh

When selecting the appropriate metal mesh for industrial applications, one of the key decisions revolves around choosing between stainless steel and carbon steel mesh. Stainless steel is well-regarded for its corrosion resistance, making it an ideal choice for environments exposed to moisture or chemicals. This durability ensures longevity and reduced maintenance costs, particularly in food processing, pharmaceuticals, and outdoor applications. Meanwhile, carbon steel offers superior strength and is generally more cost-effective, making it suitable for applications where weight and budget are critical but where the risk of rust or corrosion is minimal.

Tips: When evaluating your options, consider the specific harshness of the environment in which the metal mesh will be utilized. If you're working in a highly corrosive setting, the upfront investment in stainless steel might save you money in the long run. On the other hand, if your application demands high tensile strength and you are operating in a controlled environment, carbon steel can be a wise choice.

It’s crucial to assess not only the immediate requirements but also the long-term implications of your choice. Both stainless and carbon steel mesh can serve effectively but understanding their properties will help you maximize performance and efficiency in your industrial applications. Make sure to factor in costs, durability, and the specific challenges of your working environment to make an informed decision.

Cost-Benefit Analysis: Finding the Right Balance for Industrial Mesh Solutions

When selecting metal mesh for industrial applications, conducting a cost-benefit analysis is crucial to ensure optimal performance without overspending. According to a report by the Freedonia Group, the demand for industrial mesh products is expected to grow at a compound annual growth rate (CAGR) of 4.2% through 2025. This increase highlights the importance of balancing quality and cost, as businesses strive to enhance efficiency while managing budgets.

Investing in high-quality metal mesh can result in significant long-term savings. A study by Grand View Research indicates that durable mesh solutions can extend the lifespan of equipment by up to 30%, thereby reducing replacement costs and maintenance downtime. On the other hand, opting for lower-grade materials may initially save money, but could lead to frequent replacements and higher operational costs over time. Therefore, when assessing metal mesh options, it's essential to analyze not just upfront costs but also the total cost of ownership to determine the best solution for specific industrial needs.