How to Choose the Best Woven Mesh for Your Projects?

Choosing the right woven mesh for your projects is crucial. Woven mesh is versatile and has various applications. It’s important to understand your specific needs before selecting a type.

Consider the material. Different materials like stainless steel, aluminum, or plastic offer unique benefits. The choice affects durability, flexibility, and appearance. Think about the mesh's design as well. A tight weave may provide more strength, while a loose weave enhances airflow.

Reflect on the purpose of your project. Will it be used for privacy, security, or decoration? Each requirement influences the type of woven mesh you choose. A mismatch could lead to issues down the line. Make sure to assess your options thoroughly to avoid costly mistakes.

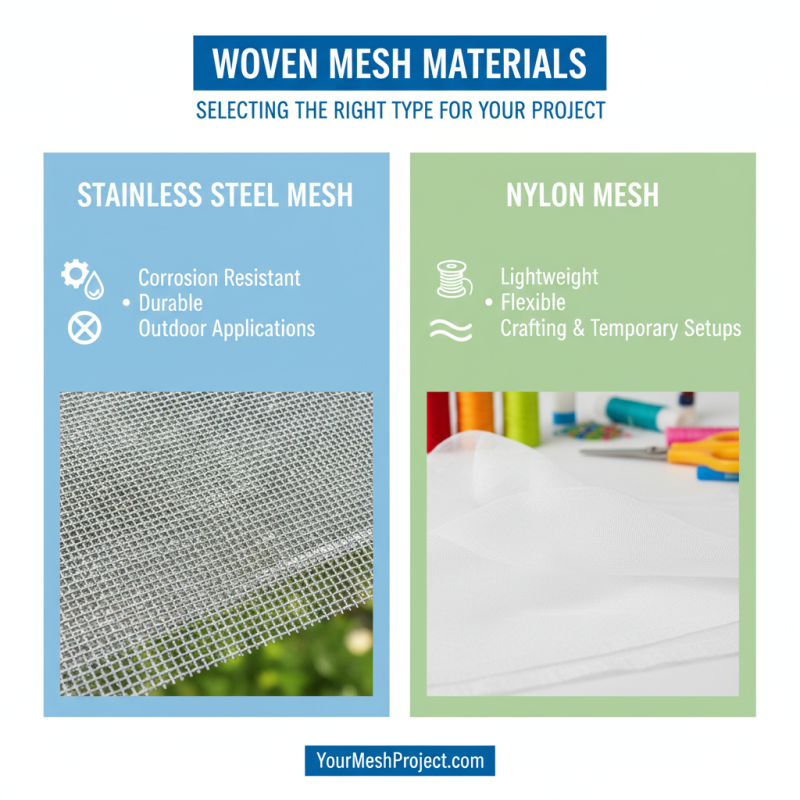

Types of Woven Mesh Materials Suitable for Various Projects

When selecting woven mesh materials, it’s crucial to consider your project's specific needs. Different types of woven mesh serve varied purposes. For example, stainless steel mesh offers corrosion resistance, making it ideal for outdoor applications. On the other hand, nylon mesh is lightweight and flexible, suitable for crafting and temporary setups.

Natural fibers like cotton or jute are often used in eco-friendly projects. They provide excellent breathability and biodegradable options. However, these materials may not withstand heavy loads as well as synthetic fibers. Another option is fiberglass mesh, which is strong and heat-resistant, perfect for industrial settings. These choices highlight the variety but can also cause confusion.

Understanding the environment is key. Some materials may perform well indoors but struggle outdoors. Think about the longevity and maintenance required for each option. Reflecting on your project’s goals helps in making the right choice. Choose wisely to ensure your woven mesh serves its intended purpose effectively.

Factors to Consider When Selecting Woven Mesh for Durability

When selecting woven mesh for your projects, durability is crucial. It determines the material's lifespan and performance under various conditions. A study by the Technical Textile Association indicates that woven mesh can last up to 10 years if made from high-quality fibers. Choosing the right fiber type can improve resistance to environmental factors, such as UV exposure and moisture.

Tips: Always verify the mesh's tensile strength. A mesh with high tensile strength can withstand heavy loads. Look for tensile ratings in specifications to ensure the mesh meets your needs.

Consider the weave pattern too. Different patterns offer distinct strengths. For example, tighter weaves typically provide more strength but may reduce airflow. A 2022 report noted that loose-weave mesh improved air circulation but decreased durability, which could require regular replacement.

Remember, not every woven mesh will suit all projects. Reflect on your specific demands carefully. Are you prioritizing strength over weight? Such decisions will heavily influence your mesh choice. Take your time to evaluate these factors, ensuring you choose wisely to avoid future regrets.

How to Choose the Best Woven Mesh for Your Projects? - Factors to Consider When Selecting Woven Mesh for Durability

| Mesh Type | Material | Wire Diameter (mm) | Open Area (%) | Durability Rating |

|---|---|---|---|---|

| Plain Weave | Stainless Steel | 1.0 | 60 | High |

| Twill Weave | Carbon Steel | 1.5 | 50 | Medium |

| Dutch Weave | Brass | 0.8 | 70 | High |

| Leno Weave | Polyester | 1.2 | 55 | Medium |

Evaluating Mesh Opening Sizes and Their Application Impact

Choosing the right woven mesh for your project is crucial. The mesh opening size significantly influences functionality. Smaller openings provide better filtration. Conversely, larger openings allow for better airflow. It's essential to assess what your primary need is. For example, in filtration systems, mesh sizes typically range from 10 to 200 microns. A report by the Filtration Society reveals that selecting the right opening size can improve efficiency by up to 30%.

Mesh materials also affect performance. Different materials like nylon, polyester, or stainless steel offer unique advantages and disadvantages. Stainless steel is durable, but costly. Nylon is less expensive but can degrade faster over time when exposed to chemicals. An industry case study indicates that over 15% of project failures stem from improper material choice. This emphasizes the need for careful consideration during the selection process.

Tips: Test your chosen mesh in a small application before full-scale deployment. This allows you to observe its practical impacts. Also, consider environmental factors that may influence mesh longevity and performance. Don't overlook the importance of feedback from previous users. Their experiences can offer valuable insights that data alone cannot provide. Remember, the right mesh can greatly alter your project's success.

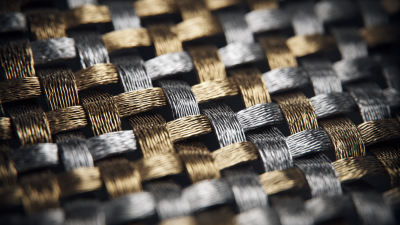

Understanding the Weave Patterns and Their Functional Benefits

Choosing the right woven mesh involves understanding the different weave patterns available. Each pattern offers various functional benefits. For instance,

plain weaves are known for their strength and durability. They provide excellent stability, suitable for high-stress applications.

Studies indicate that plain woven meshes can endure up to 50% more load than other patterns.

Twill weaves, on the other hand, are more flexible and resistant to fraying. They have a unique diagonal pattern that increases their breathability.

According to industry reports, twill meshes can enhance airflow by 30%, making them ideal for applications where ventilation is crucial.

However, one should consider if this increased breathability might compromise strength in high-load scenarios.

Another option is satin weaves. They have a smoother surface which can reduce wear. Yet, their lack of rigidity may lead to concerns in certain projects.

Many users have reported that satin meshes sometimes fail to provide adequate support. Selecting the right mesh means assessing the balance between flexibility and strength based on your specific needs.

Examining these aspects closely can lead to more effective project outcomes, but careful thought is necessary to avoid potential missteps.

Budgeting for Woven Mesh: Cost-Effective Solutions and Sourcing Tips

When budgeting for woven mesh, start by assessing your project needs. Different applications require different mesh types. Consider the material, durability, and potential wear and tear. Some projects may not need the highest quality mesh. It's important to find a balance between cost and functionality.

Sourcing tips are essential. Look for local suppliers to save on shipping costs. Compare prices from various vendors. Sometimes, bulk purchases can lead to significant savings. Don't hesitate to inquire about discounts or sample options. Exploring online marketplaces may also reveal hidden gems.

Crafting a budget isn't always straightforward. Unexpected costs can arise. You might underestimate the amount of mesh required. Be flexible and allow room for adjustments. Ultimately, focus on achieving quality without overspending. Investing time in research pays off in the end. Choices made now can prevent headaches later on.

Related Posts

-

Exploring the Versatility of Woven Mesh: Innovative Applications Across Industries

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Woven Wire for Your Project Needs

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

2025 Top 5 Fine Metal Mesh Products for Enhanced Performance and Durability