2025 How to Choose the Best Braided Wire for Your Projects

When embarking on various projects, whether in crafting, electrical work, or industrial applications, selecting the right materials is crucial for success. Among the many options available, braided wire stands out due to its unique properties and versatility. This article delves into the essential factors to consider when choosing the best braided wire for your specific needs.

Braided wire is known for its enhanced strength and flexibility, making it ideal for applications that require durability and resilience. Understanding the characteristics of different types of braided wire can help you make informed decisions that will ultimately lead to better project outcomes. From the wire's gauge and material composition to its intended use and environmental conditions, each aspect plays a significant role in ensuring the wire performs optimally.

Choosing the right braided wire can significantly influence the efficiency and effectiveness of your projects. This guide will provide valuable insights into distinguishing various options and selecting the most suitable braided wire tailored to your requirements. Whether you're a seasoned professional or a DIY enthusiast, by the end of this article, you'll be equipped with the knowledge needed to make the best choice for your next project.

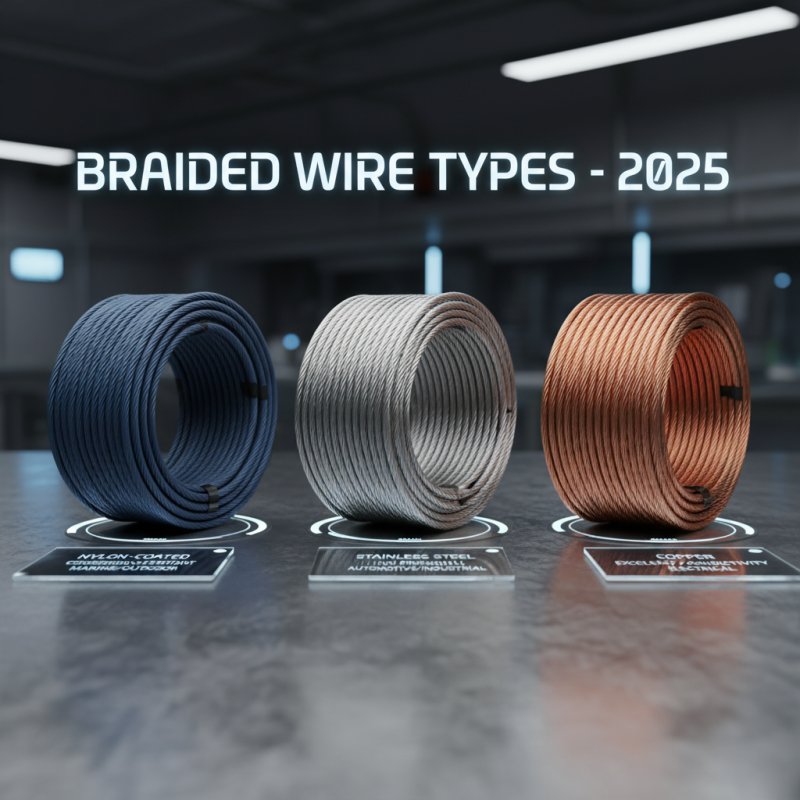

Understanding Braided Wire: Types and Their Applications in 2025

Braided wire has become increasingly popular in various applications due to its superior strength and flexibility. In 2025, understanding the different types of braided wire is essential for selecting the right one for your project. Common types include nylon-coated, stainless steel, and copper braided wires. Nylon-coated braided wire is renowned for its resistance to corrosion and wear, making it ideal for outdoor projects and marine applications. Stainless steel braided wire offers exceptional strength and durability, often used in automotive and industrial settings. Copper braided wire is favored for electrical applications due to its excellent conductivity and flexibility.

Each type of braided wire has its specific applications suited to its properties. For example, nylon-coated braided wire can be used for securing outdoor equipment, while stainless steel is often employed in high-tension situations, such as rigging or lifting. Conversely, copper braided wire is essential for grounding and electrical connections. When selecting a braided wire in 2025, it is crucial to consider not only the material and coating but also the specific demands of your project to ensure optimal performance and longevity.

Key Factors to Consider When Selecting Braided Wire for Projects

When selecting braided wire for your projects, there are several key factors to consider to ensure optimal performance and durability. First, assess the material of the braided wire. Common options include stainless steel, copper, and nylon-coated wires, each offering distinct characteristics. Stainless steel is known for its strength and corrosion resistance, making it suitable for outdoor or marine applications, while copper provides excellent conductivity for electrical projects. Meanwhile, nylon-coated wire can enhance flexibility and protect against abrasion.

Another crucial aspect to consider is the wire’s gauge and braid count. The gauge determines the wire's thickness, impacting its current-carrying capacity and strength. A higher gauge number indicates a thinner wire, which may not be suitable for heavy-duty tasks. Additionally, the braid count affects flexibility and resilience; a higher number of braids often results in greater flexibility, allowing the wire to navigate tight spaces easily. Therefore, evaluating your project's specific needs regarding material, gauge, and braid count is essential for selecting the best braided wire.

2025 How to Choose the Best Braided Wire for Your Projects

Industry Standards: Evaluating the Quality of Braided Wire Materials

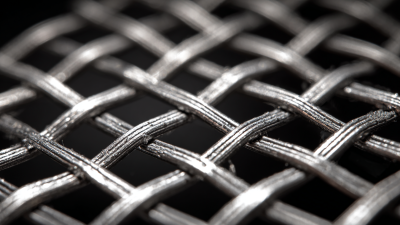

When selecting braided wire for various projects, understanding industry standards is essential in evaluating the quality of the materials used. Braided wire is often composed of multiple strands intertwined to provide flexibility, durability, and strength. However, not all braided wires are created equal; the materials and construction methods greatly influence their performance and longevity. Key factors to consider include the type of metal used, the diameter of the strands, and the overall braid density. Adhering to established industry standards ensures that the wire meets the necessary specifications for its intended application, whether it’s for electrical wiring, mechanical assemblies, or other uses.

Another crucial aspect of evaluating braided wire quality is to consider certifications and compliance with safety regulations. Look for products that meet or exceed standards set by organizations such as the American National Standards Institute (ANSI) or the International Electrotechnical Commission (IEC). Additionally, the wire's resistance to environmental factors like temperature extremes, corrosion, and mechanical wear should be assessed. By focusing on these criteria, one can confidently choose braided wire that not only suits the needs of their project but also guarantees safety and reliability in performance measurements.

Comparative Analysis: Cost vs. Performance of Different Braided Wires

When selecting braided wire for your projects, understanding the cost versus performance dynamics is crucial. Different braided wires are made from various materials, such as stainless steel, nylon, and copper, each offering unique performance characteristics that may justify their price. For instance, stainless steel braided wire generally provides greater strength and durability, making it suitable for high-stress applications, while nylon offers flexibility and resistance to abrasion at a lower cost. Analyzing the specific requirements of your project will help you determine which material offers the best balance between cost and performance.

Additionally, performance factors like tensile strength, resistance to corrosion, and fatigue life should be considered alongside cost. While a more expensive option might seem daunting, its long-term durability and reduced maintenance can lead to overall cost savings. In contrast, while a cheaper wire may initially appear to be a better deal, it could result in higher replacement costs and downtime. Ultimately, a thoughtful comparison of these elements will enable you to select the most appropriate braided wire for your needs, ensuring that your projects are both effective and economically viable.

2025 How to Choose the Best Braided Wire for Your Projects - Comparative Analysis: Cost vs. Performance of Different Braided Wires

| Wire Type | Cost per Meter ($) | Tensile Strength (N) | Flexibility Rating | Corrosion Resistance (Rating) | Recommended Applications |

|---|---|---|---|---|---|

| Type A | 0.50 | 250 | High | 5 | Electrical Wiring |

| Type B | 0.75 | 300 | Medium | 4 | Heavy Machinery |

| Type C | 1.00 | 350 | Low | 3 | Marine Applications |

| Type D | 1.25 | 200 | Medium | 5 | Construction |

Future Trends in Braided Wire Technology for Enhanced Project Efficiency

In the evolving landscape of braided wire technology, future trends are increasingly focused on enhancing project efficiency through innovation. According to a recent report by Grand View Research, the global braided wire market is expected to reach USD 5.2 billion by 2026, driven by advancements in materials and manufacturing techniques. This growth indicates a robust demand for high-performance braided wires that can meet the stringent requirements of various industries, including aerospace, automotive, and telecommunications.

Tips for selecting the right braided wire for your projects include considering the material’s conductivity and tensile strength. High-quality materials such as copper and aluminum offer superior performance in electrical applications, while specialized composites can enhance durability in harsh environments. It is also essential to assess the wire's flexibility and resistance to corrosion, which can significantly affect its lifespan and reliability in demanding applications.

Furthermore, a greater emphasis on sustainability is shaping future trends in braided wire technology. Companies are increasingly seeking eco-friendly solutions, with reports suggesting that the use of recycled materials in wire production could reduce carbon footprints by up to 30%. Embracing these innovations not only boosts project efficiency but also aligns with global sustainability goals.

Related Posts

-

Exploring the Benefits of Screen Mesh in Modern Home Renovations

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Exploring the Benefits of Fine Mesh Filters in Sustainable Home Brewing

-

What is Cable Mesh and How It Revolutionizes Modern Construction

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project