Top 10 Tips for Choosing the Right Stainless Steel Mesh Screen for Your Needs

When it comes to selecting the right stainless steel mesh screen for your specific needs, the options can be overwhelming. These versatile screens serve a multitude of purposes across various industries, from filtration to safety applications, making it essential to understand the key factors to consider before making a decision. A well-chosen stainless steel mesh screen can greatly enhance the efficiency and safety of your projects, while a poor selection may lead to unnecessary complications and costs.

In this guide, we will explore the top ten tips for choosing the ideal stainless steel mesh screen tailored to your requirements. From understanding mesh size and wire diameter to evaluating corrosion resistance and strength, these tips will provide you with the knowledge needed to make an informed choice. Whether you are a contractor, engineer, or DIY enthusiast, recognizing the attributes of stainless steel mesh screens will ensure that you select the most appropriate product for your application. Being informed about these factors not only facilitates better performance but also prolongs the lifespan of your investment. Let’s delve into the essential aspects of making the right decision in your search for the perfect stainless steel mesh screen.

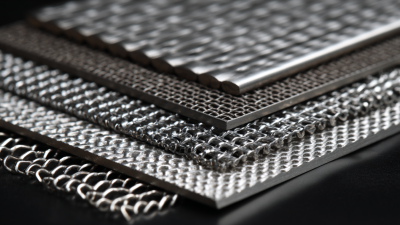

Understanding the Different Types of Stainless Steel Mesh Screens

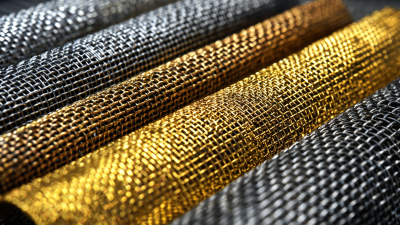

When selecting the right stainless steel mesh screen, it is essential to first understand the different types available, as each serves specific purposes and applications. There are several classifications based on mesh size, opening pattern, and wire diameter. For instance, fine mesh screens possess smaller openings, making them ideal for filtration applications, while coarse mesh screens with larger openings are better suited for ventilation or protective barriers. The choice of mesh type directly impacts the efficiency of the intended use, whether for industrial, agricultural, or domestic needs.

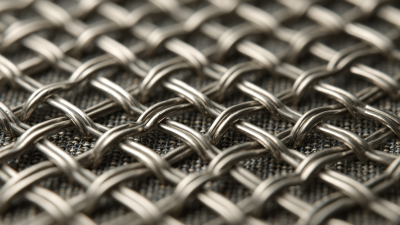

Additionally, the construction and materials of the mesh are critical to its performance. Stainless steel mesh screens can vary in terms of weave styles, such as plain weave or twill weave, affecting their strength and flexibility. The wire diameter also contributes significantly to the overall durability; thicker wires provide increased stability, making them perfect for heavy-duty applications. Understanding these variations enables consumers to make informed decisions that align with their specific requirements, ensuring they select a stainless steel mesh screen that performs optimally in its intended environment.

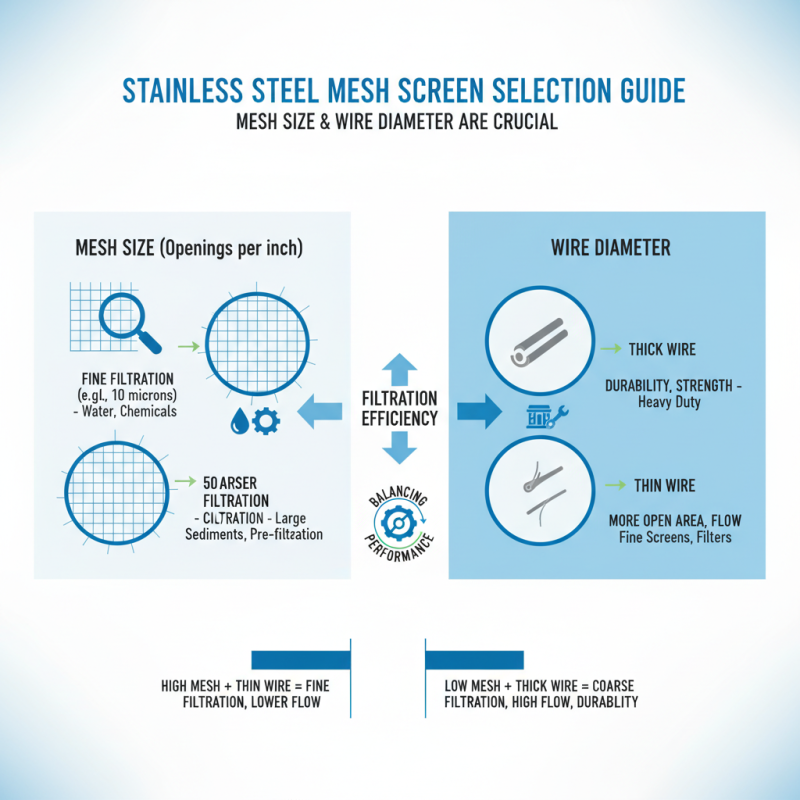

Evaluating Mesh Size and Wire Diameter for Your Requirements

When selecting the appropriate stainless steel mesh screen for specific applications, evaluating mesh size and wire diameter is crucial. Mesh size, which refers to the number of openings per linear inch, directly influences the screen’s filtration capabilities. According to a report by the Industrial Fabrics Association International, different mesh sizes can capture particles as small as 10 microns, making them suitable for various applications in industries ranging from water filtration to architectural designs. For instance, a standard mesh size of 200 can effectively filter out small sediments while allowing smoother fluid flow, thus balancing filtration efficiency and process performance.

Wire diameter, on the other hand, plays a significant role in the durability and strength of the mesh screen. A thicker wire provides increased resistance to mechanical stress and is essential for high-load applications, as noted in the Stainless Steel Wire Cloth Association's technical guidelines. Data indicates that screens with a wire diameter of 0.025 inches are typically used in applications requiring high strength without significantly sacrificing mesh openings. Understanding the interplay between mesh size and wire diameter ensures that the selected screen meets both the filtration requirements and the rigors of the intended environment, ultimately leading to improved operational efficiency and longevity of the installation.

Considering Corrosion Resistance and Durability Factors

When selecting a stainless steel mesh screen, evaluating corrosion resistance and durability is paramount. Stainless steel's ability to withstand corrosive environments depends largely on its alloy composition. According to the International Stainless Steel Forum (ISSF), austenitic stainless steel grades, such as 304 and 316, are known for their excellent corrosion resistance due to the presence of chromium and nickel. The addition of molybdenum in 316 grade further enhances its resistance to pitting corrosion, especially in chloride environments, making it a preferred choice for marine applications.

Durability is another critical factor to consider, which can be influenced by the wire diameter and mesh pattern. A report from the Metal Mesh Manufacturers Association (MMMA) indicates that screens with a thicker wire diameter inherently support higher tensile strength and, thus, offer better performance under physical stress. Users should also assess the intended application environment—whether it’s subjected to high temperatures, varying pH levels, or exposure to harsh chemicals. Understanding these specifications and the operational setting will ensure that the selected stainless steel mesh screen not only resists corrosion effectively but also maintains its integrity over time, ultimately leading to a more reliable and long-lasting solution for various filtration or structural needs.

Top 10 Tips for Choosing the Right Stainless Steel Mesh Screen for Your Needs - Considering Corrosion Resistance and Durability Factors

| Tip No. | Tip | Corrosion Resistance | Durability |

|---|---|---|---|

| 1 | Select the right grade of stainless steel. | Look for grades like 304 and 316 for better resistance. | Grade 316 is more durable and better for marine environments. |

| 2 | Check mesh size and openings. | Ensure appropriate size to prevent clogging. | Larger mesh may wear out faster depending on usage. |

| 3 | Consider the method of use. | High humidity environments need better corrosion resistance. | Assess stress and load to determine durability needs. |

| 4 | Evaluate temperature conditions. | High temperatures can affect corrosion properties. | Ensure mesh can withstand operational temperatures without degradation. |

| 5 | Assess chemical exposure. | Different chemicals may require specific mesh materials. | Evaluate compatibility to enhance longevity. |

| 6 | Look for certifications. | Certifications ensure materials meet industry standards. | Credible certifications indicate reliability and durability. |

| 7 | Consult manufacturer specifications. | Specifications include details on corrosion rates. | Durability ratings can also be found in product literature. |

| 8 | Evaluate maintenance needs. | Lower maintenance equals better long-term resistance. | Durable meshes require less frequent replacement. |

| 9 | Consider environmental factors. | Environmental stresses can cause rapid corrosion. | Durability will vary with changing environmental conditions. |

| 10 | Ask for expert advice. | Consultation can provide insights on corrosion and durability. | Experts can recommend the best mesh for specific applications. |

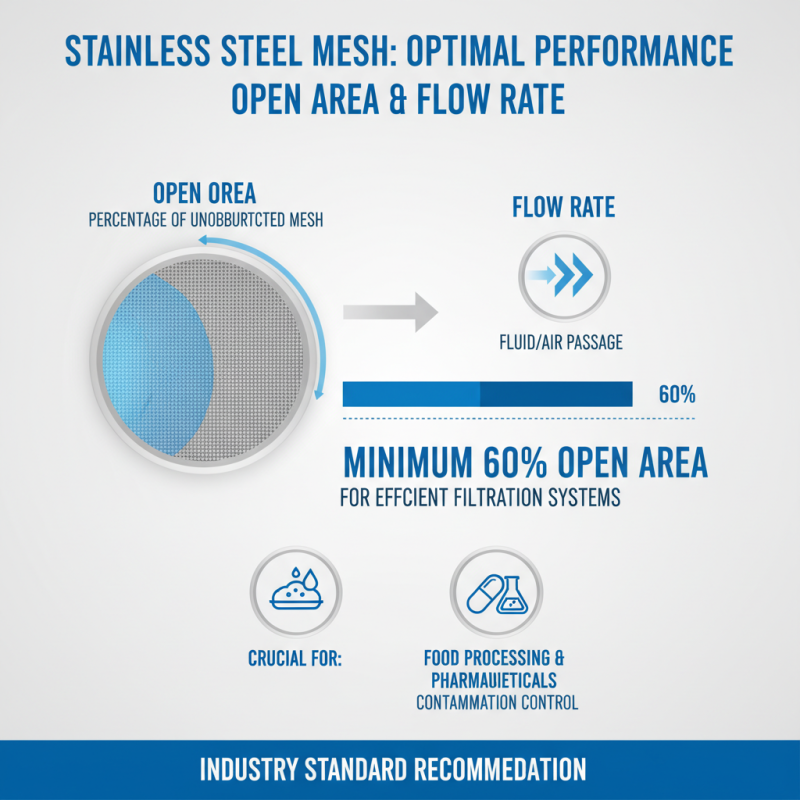

Assessing Open Area and Flow Rate for Optimal Performance

When selecting the right stainless steel mesh screen, assessing the open area and flow rate is crucial for ensuring optimal performance. Open area refers to the percentage of the mesh that is not obstructed by wire, allowing fluids or air to pass through. According to industry standards, a minimum open area of 60% is typically recommended for applications in filtration systems to maintain efficient flow rates without compromising the filtration quality. This is essential in industries such as food processing and pharmaceuticals, where contamination control is paramount.

Flow rate, on the other hand, is a measurement of how much fluid can pass through the mesh screen over a given time. A study by the American Society of Mechanical Engineers indicates that screens with a higher open area generally support better flow rates. For instance, a mesh screen with 70% open area can facilitate a flow rate increase of up to 25% compared to a screen with only 50% open area. Therefore, choosing a screen with the appropriate balance of mesh thickness and open area will directly impact efficiency, reduce pressure loss, and enhance system longevity. When evaluating options, it’s essential to conduct a thorough analysis of your specific operational demands, considering both the types of materials being filtered and the required throughput to select the optimal stainless steel mesh screen.

Identifying Suitable Applications for Various Stainless Steel Screens

When selecting the right stainless steel mesh screen, understanding its various applications is crucial. Stainless steel screens are commonly used in industries such as food processing, pharmaceuticals, and construction due to their durability and resistance to corrosion. For instance, in food processing, hygienic standards necessitate the use of materials that can withstand cleaning and sterilization processes. A fine mesh screen can effectively filter out contaminants while remaining easy to clean, ensuring food safety and compliance with health regulations.

In the construction sector, stainless steel mesh screens serve multiple functions, including reinforcement in concrete and protection against pests. Their structural integrity makes them ideal for use in architectural screens and facades, combining functionality with aesthetic appeal. Moreover, understanding the specifications required for your application—such as the mesh size, wire diameter, and overall strength—will help you select the most suitable screen. Whether you need a coarse mesh for drainage or a finer mesh for filtration, a clear understanding of your project requirements will guide you in choosing the right stainless steel screen that meets your needs efficiently.

Related Posts

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

-

Exploring the Versatility of Stainless Steel Mesh in Modern Applications

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

How to Choose the Right Metal Mesh for Your Industrial Applications