How to Choose the Right Stainless Mesh for Your Specific Applications

When selecting the appropriate stainless mesh for your specific applications, it is essential to consider various factors that can significantly impact both functionality and performance. Stainless mesh, known for its durability, corrosion resistance, and versatility, comes in a range of types, sizes, and weave patterns tailored to meet different industry needs. Understanding your specific requirements—whether for filtration, fencing, or architectural features—will guide you in making the right decision. This guide will provide insights into the critical aspects of stainless mesh selection, including material grade, mesh size, and intended use, ensuring that you choose a product that not only meets your standards but also enhances the efficiency of your operations. By the end of this article, you will be equipped with the knowledge necessary to make an informed choice that aligns with your project goals.

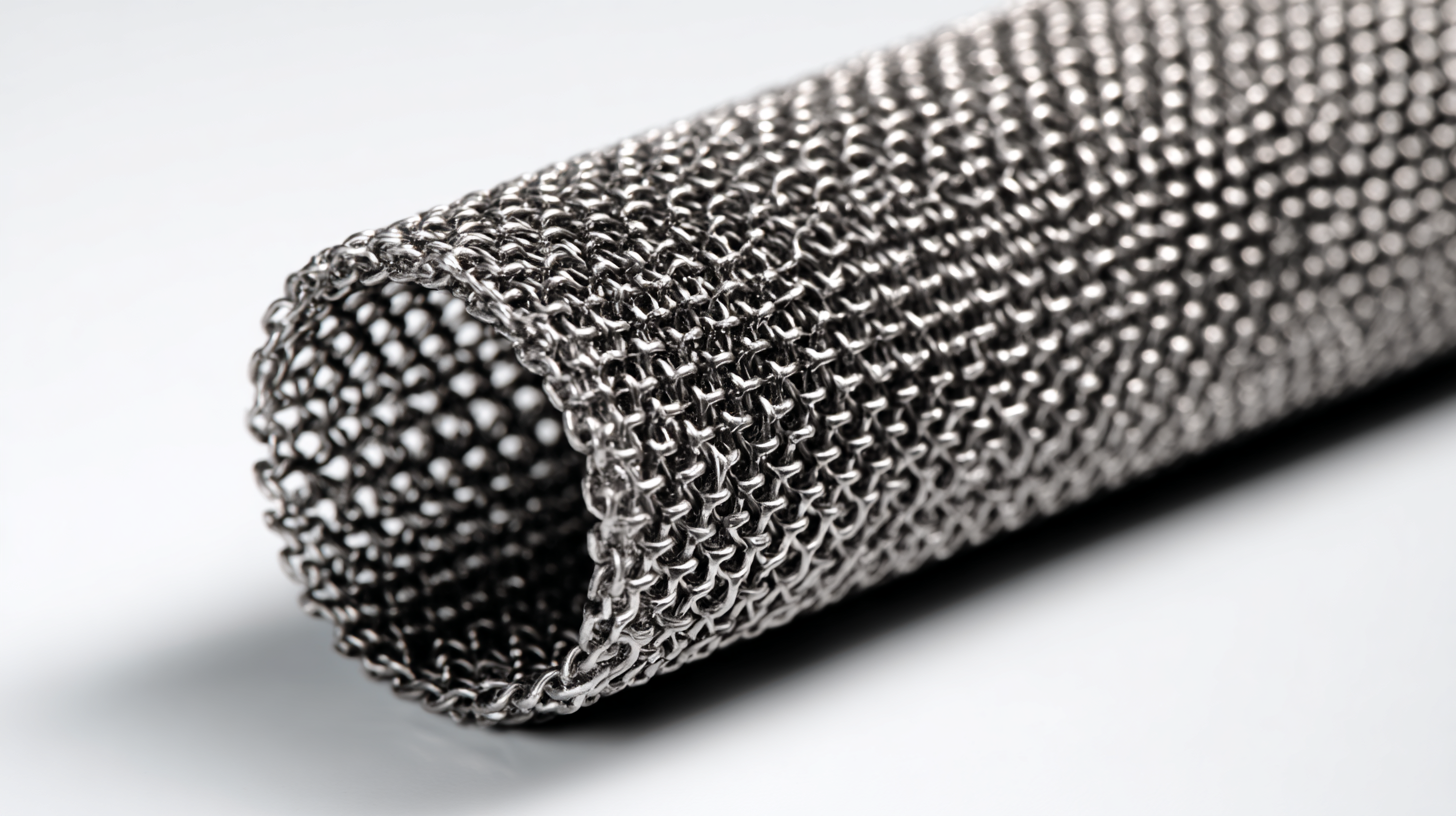

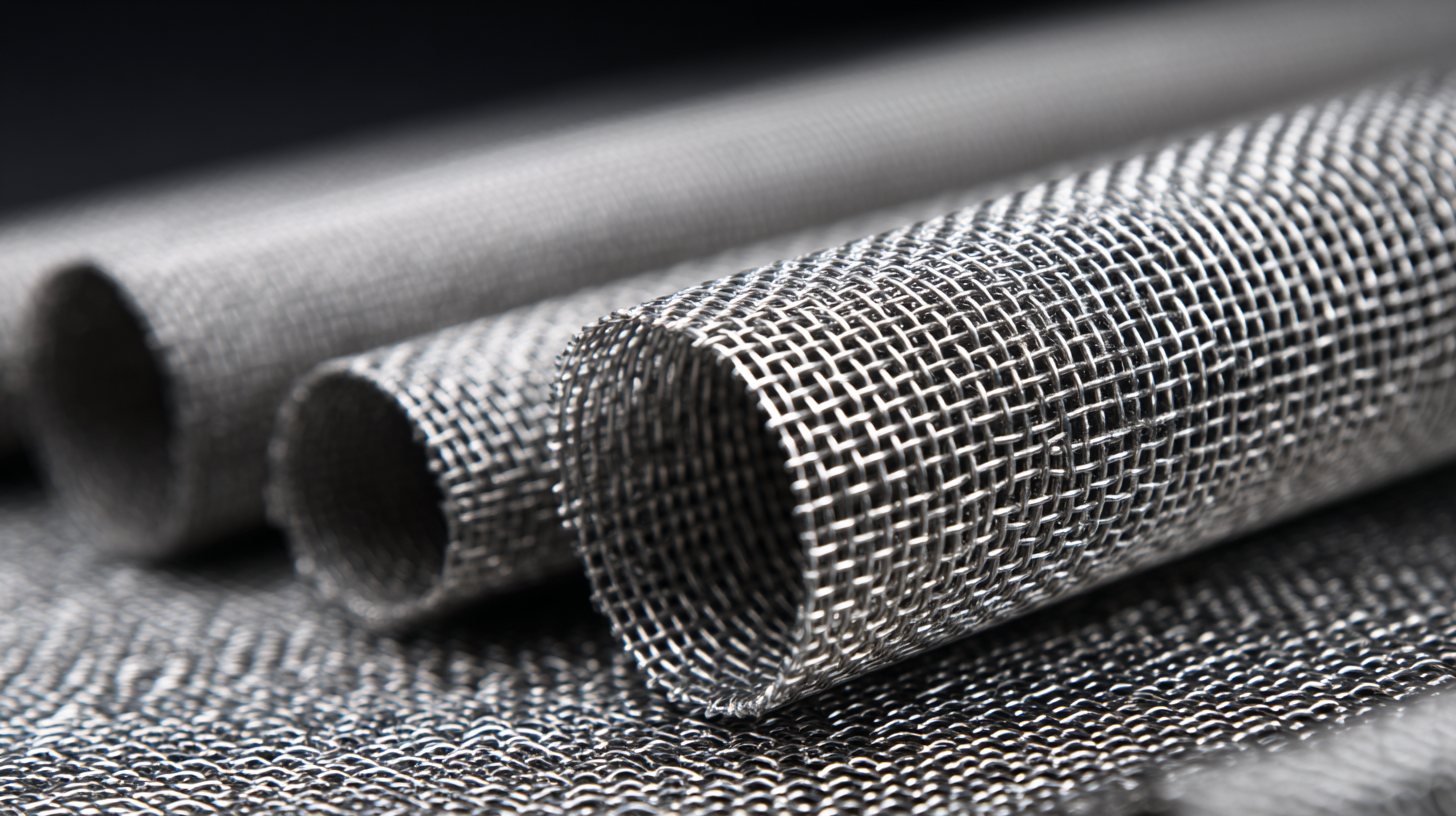

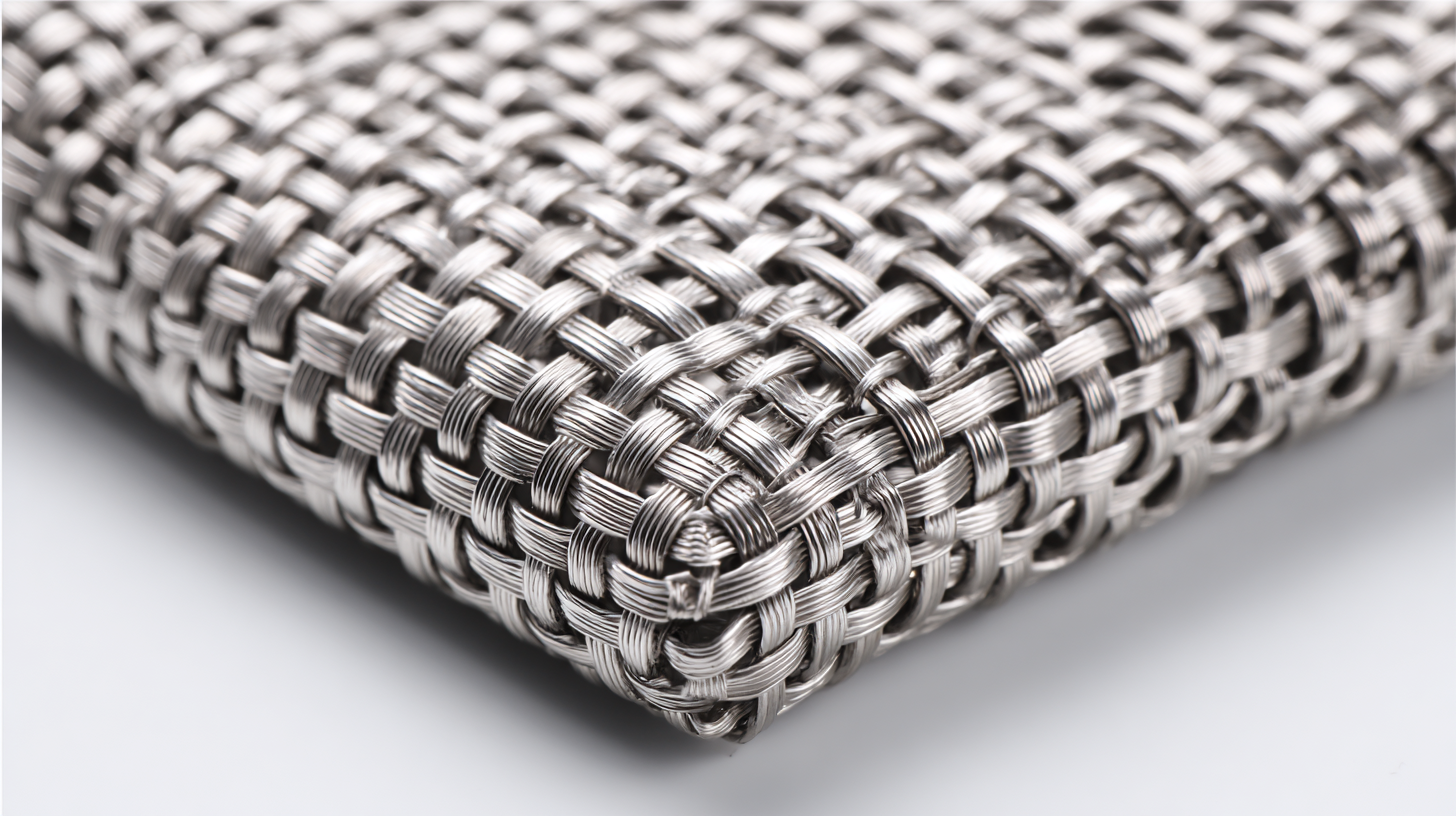

Understanding Different Types of Stainless Steel Meshes and Their Properties

Stainless steel meshes are versatile materials widely used across various industries, thanks to their durability, corrosion resistance, and structural integrity. Understanding the different types of stainless steel meshes is crucial for selecting the right one for specific applications. The primary classifications include woven wire mesh, welded wire mesh, and perforated sheets, each with distinct properties. For instance, woven wire mesh offers excellent flexibility and is commonly used in filtration applications, while welded wire mesh provides greater strength and stability, making it ideal for construction and reinforcement purposes.

A recent report by MarketsandMarkets indicates that the global market for stainless steel mesh is projected to reach $1.2 billion by 2025, driven largely by the increased demand in various sectors such as food and beverage, pharmaceuticals, and automotive industries. Properties such as tensile strength and gauge size significantly impact performance; for example, finer meshes are preferred for applications requiring filtration of small particles, whereas larger meshes are utilized for strength applications. By understanding these distinctions and properties, businesses can make informed decisions when selecting the most suitable stainless steel mesh for their needs.

Evaluating Mesh Openings and Wire Gauges for Optimal Performance

When selecting the appropriate stainless mesh for your specific applications, it is crucial to carefully evaluate both mesh openings and wire gauges. The mesh opening refers to the size of the gaps between the wires, which significantly influences the material's filtering capabilities. For applications requiring fine filtration, such as in pharmaceuticals or food processing, smaller openings are essential to prevent the passage of unwanted particles. Conversely, larger openings are suitable for applications where airflow is prioritized, such as in certain industrial settings.

Wire gauges, on the other hand, describe the thickness of the individual wires used to construct the mesh. A higher gauge indicates a thinner wire, which can be advantageous for applications needing flexibility or lightness. However, thinner wires may compromise strength and durability, particularly in high-stress environments. Conversely, lower gauges provide enhanced strength and can withstand higher pressures, making them ideal for robust applications like mining or heavy machinery. By carefully evaluating these factors, you can ensure that the selected stainless mesh meets the specific demands of your application while optimizing performance.

How to Choose the Right Stainless Mesh for Your Specific Applications

| Application | Mesh Opening (Microns) | Wire Gauge | Typical Use |

|---|---|---|---|

| Filtration | 25 | 200 | Liquid and gas filtration |

| Security | 10 | 12 | Fencing and safety barriers |

| Sifting | 500 | 40 | Food processing and chemical industries |

| Ventilation | 15 | 20 | Air filtration and circulation |

| Separation | 100 | 30 | Mining and mineral processing |

Considering Corrosion Resistance and Environmental Factors in Your Selection

When selecting the right stainless mesh for specific applications, considering corrosion resistance and environmental factors is crucial. Different types of stainless steel, such as 304 and 316, exhibit varying levels of corrosion resistance. For environments exposed to harsh chemicals or saline conditions, opting for a higher grade like 316 stainless steel is advisable due to its enhanced resistance to pitting and crevice corrosion. Understanding the specific environmental conditions your mesh will face can significantly influence its longevity and performance.

Tip: Always assess the potential environmental factors such as moisture, temperature fluctuations, and chemical exposure when choosing your mesh material. Performing a site analysis can help predict how these factors will interact with different stainless steel grades.

In addition to corrosion resistance, consider the mesh's practical application. Whether it’s for filtration, architectural design, or protective screens, the environment will dictate the necessary specifications. The right mesh not only meets the physical demands of your project but also ensures durability and efficiency over time.

Tip: Consult with manufacturers regarding the performance characteristics of various stainless steel types. They can provide valuable insights and recommendations based on their expertise and experience in similar applications.

Assessing Load Capacity and Mechanical Strength for Specific Applications

When selecting the appropriate stainless mesh for specific applications,

assessing load capacity

and mechanical strength

is crucial. According to a report by the Stainless Steel Recycling Institute,

the mechanical properties of stainless steel, including yield strength and tensile strength,

vary significantly depending on the grade and wire diameter. For instance,

304 stainless steel

typically exhibits a yield strength of about 215 MPa,

while 316 grades can reach up to 290 MPa.

This difference can heavily influence the mesh's performance under load.

In applications where weight-bearing is critical,

such as in industrial filtration or construction,

it’s essential to evaluate the mesh's load capacity.

The American Society for Testing and Materials (ASTM) outlines standardized tests that help determine

the maximum load a particular mesh can endure before failure.

For example, a mesh with a wire diameter of 0.5mm

might have a much higher load capacity than that of 0.2mm,

significantly impacting its suitability for heavy-duty applications.

Consequently, understanding these mechanical strengths and selecting the right grade of stainless steel

based on specific application requirements leads to enhanced performance and longevity of the mesh.

Identifying Cost-Effective Solutions Without Compromising Quality

When selecting the appropriate stainless mesh for specific applications, finding cost-effective solutions without sacrificing quality is paramount. According to a 2022 report from the Global Mesh Market Analysis, stainless steel mesh is projected to grow at a 5.8% CAGR from 2023 to 2028, driven by its high corrosion resistance and durability. While the initial investment might seem substantial, companies must consider the long-term benefits of using quality materials, which can significantly reduce maintenance costs and downtime.

Moreover, industry experts suggest that investing in higher-grade stainless steel can yield better performance and longevity. For instance, 316 stainless steel offers enhanced resistance to chlorides compared to the more common 304 grade, making it a superior choice for marine and chemical processing environments. A case study from the International Stainless Steel Forum highlights that systems using premium stainless mesh achieved a 30% longer lifespan before requiring replacement, directly impacting operational efficiency and cost savings. This data underscores the importance of balancing upfront costs with potential long-term savings when choosing the right stainless mesh for specific applications.