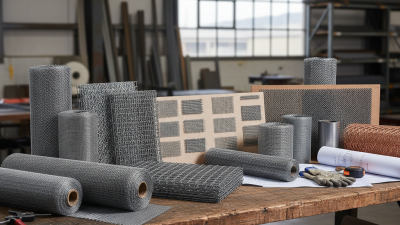

How to Choose the Right Wire Mesh for Your Project Needs

Choosing the right wire mesh for your project is crucial. Wire mesh is versatile and used in various applications, from construction to agriculture. According to industry reports, the global wire mesh market is expected to reach over $8 billion by 2026. This growth reflects its importance in many sectors.

When selecting wire mesh, consider factors like material, mesh size, and application. Steel wire mesh is popular for its strength. In contrast, plastic options are lightweight and corrosion-resistant. Yet, many people overlook the significance of proper sizing. A mismatch can lead to project failures or increased costs.

Quality matters too. Not all wire mesh products are created equal. Thicker wires increase durability but can be harder to work with. This balance between strength and ease of use can be challenging. Reflecting on these details can guide you toward the right choice.

Understanding the Types of Wire Mesh: A Comprehensive Overview

When considering wire mesh, it’s crucial to understand the available types. Wire mesh varies in material, size, and weave pattern. For example, stainless steel mesh is durable and suitable for harsh environments. Galvanized wire mesh offers corrosion resistance and is often used in outdoor settings. Meanwhile, welded wire mesh provides stability and is commonly found in construction projects.

Tip: Think about the location of your project. Is it exposed to moisture? Choose materials accordingly.

Different applications require different mesh specifications. For gardening, fine mesh prevents pests while allowing sunlight through. In industrial settings, thicker mesh supports heavier loads. Each choice impacts functionality.

Tip: Make a list of your project needs. Include factors like load-bearing capacity and environmental exposure. This can clarify which type works best.

Overall, finding the right wire mesh involves careful consideration. Take time to evaluate your options. Sometimes, a mesh that seems ideal may not be the best fit after all. Adjust your criteria as necessary.

Key Factors to Consider When Selecting Wire Mesh for Specific Applications

When selecting wire mesh, consider the specific application. Different projects require different properties. For instance, a filtration project needs finer mesh with smaller openings. In contrast, a security application may require heavier gauge steel with larger openings for strength. The material choice also impacts performance. Stainless steel may be better for corrosion resistance, while plastic might be lighter and more affordable.

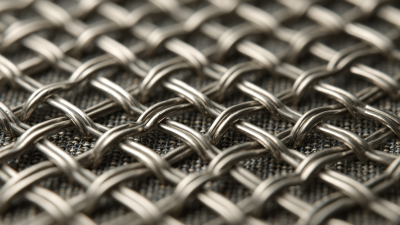

Another key factor is the mesh design. Some projects need welded wire mesh for durability, while others may benefit from woven mesh for flexibility. Always think about where the mesh will be used. Indoor uses might have fewer restrictions than outdoor environments. Remember to evaluate the load and pressure the mesh will endure. A failure to do this can lead to costly mistakes and safety issues.

Reflect on your project’s specific demands. It’s essential to match the mesh type to usage. Don’t overlook the potential for miscalculations. Consider consulting with professionals if unsure. Each aspect counts, and small details can alter the entire project’s success.

Industry Standards and Specifications for Wire Mesh Materials

When selecting wire mesh, industry standards and specifications play a crucial role. Different applications require specific material types and mesh configurations. The choice of wire diameter, mesh opening, and weave pattern can significantly impact the functionality of the mesh. For instance, tighter mesh may offer better security or filtration, while looser mesh could enhance airflow or drainage.

Understanding the specifications is key. Look into the mesh's tensile strength and corrosion resistance. These factors determine the longevity and durability of the wire mesh in various environments. Not all materials are created equal, which can lead to complications in real-world applications. Consider the mesh's intended use carefully.

However, sometimes the details can be overwhelming. Many projects may also overlook the importance of installation methods and support structures. These aspects can affect the overall performance of the wire mesh. Being aware of these standards can help avoid costly mistakes later on. Reflecting on these specifications ensures better alignment with your project’s needs.

Common Applications of Wire Mesh: Choosing the Right Type for Each Task

When selecting wire mesh for specific tasks, consider its common applications. Each type serves a unique purpose. For example, welded wire mesh is often used in construction for reinforcing concrete. Its strength and durability are essential for structural integrity. However, it may not be the best choice for projects requiring flexibility.

On the other hand, woven wire mesh is widely utilized in filtration tasks. This type allows for airflow while keeping larger particles out. Choosing the right size of openings is crucial to ensure effectiveness in various applications. Many projects fail because the mesh type does not align with the intended use. This mistake can lead to unnecessary delays and extra costs.

Another option is stainless steel mesh, known for its corrosion resistance. It is ideal for outdoor applications. But, it tends to be more expensive than other types. In some situations, it might be overkill. Assess the environment carefully before making a choice. Each decision in selecting wire mesh affects the overall success of your project. Taking time to reflect on these criteria may yield better results.

How to Choose the Right Wire Mesh for Your Project Needs

| Application | Recommended Wire Mesh Type | Material | Wire Gauge | Typical Uses |

|---|---|---|---|---|

| Animal Enclosures | Hexagonal Wire Mesh | Galvanized Steel | 14-16 Gauge | Hutches, Poultry Fencing |

| Construction | Welded Wire Mesh | Reinforced Steel | 10-12 Gauge | Concrete Reinforcement |

| Gardening | Hardware Cloth | Stainless Steel | 19-23 Gauge | Chicken Coops, Garden Fencing |

| Security Fencing | Chain Link Fence | Galvanized Steel | 9-11 Gauge | Perimeter Fencing |

| Industrial Applications | Expended Metal Mesh | Aluminum | 14-16 Gauge | Walkways, Grills |

Evaluating Wire Mesh Durability: Strength, Corrosion Resistance, and Maintenance

When evaluating wire mesh durability, strength is a crucial factor. Different projects require unique levels of strength. For heavy-duty applications, opt for thicker wire gauges. For lighter tasks, thinner wires may suffice. However, finding the balance can be tricky. Too much strength can lead to unnecessary costs, while too little can risk safety.

Corrosion resistance is another vital aspect to consider. Exposure to moisture, chemicals, or harsh environments can significantly affect longevity. Stainless steel offers superior resistance, but it comes with a higher price tag. On the other hand, coated options may be budget-friendly but could require more maintenance. Think about your project's specific environment before making a choice.

Maintenance is often overlooked but is essential for preserving wire mesh's lifespan. Regular inspections can identify early signs of wear. Neglecting maintenance can lead to gradual deterioration. This aspect invites reflection on long-term costs versus initial investments. A well-maintained mesh can outlive cheaper alternatives, highlighting the importance of proactive care. Make a thoughtful choice for the best outcome.

Evaluating Wire Mesh Durability

Related Posts

-

How to Choose the Best Wire Mesh Products for Your Project Needs

-

How to Choose the Right Wire Mesh Products for Your Project Needs

-

10 Essential Tips for Choosing the Right Metal Wire Mesh for Your Project

-

How to Choose the Best Wire Mesh for Your Home and Garden Projects

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!