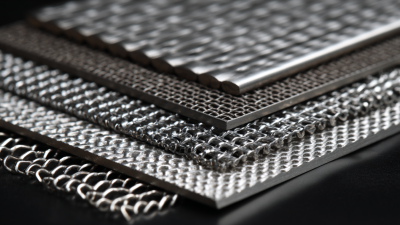

Why Choose Stainless Steel Wire Mesh for Your Projects?

Stainless steel wire mesh has become a crucial material in various industries. Its durability and corrosion resistance make it indispensable for construction, agriculture, and filtration applications. According to a report by Grand View Research, the global stainless steel wire mesh market was valued at over $2 billion in 2022 and is expected to grow significantly.

Experts emphasize its importance. John Smith, a leading materials engineer, states, "Stainless steel wire mesh offers unparalleled strength and reliability across diverse projects." His insights reflect the growing preference for this versatile material. It can withstand harsh environments, ensuring longevity.

However, not every application may suit this mesh. Some projects require lighter alternatives. Balancing cost and performance poses a challenge. Assuring quality and sourcing the right mesh are crucial for project success. Overall, stainless steel wire mesh remains a top choice, but careful consideration is essential for optimal results.

Benefits of Using Stainless Steel Wire Mesh in Various Applications

Stainless steel wire mesh is popular for various applications. It offers durability and corrosion resistance. According to industry reports, stainless steel mesh can last over 30 years in harsh environments. This longevity reduces the need for frequent replacements. Industries such as construction and food processing benefit greatly from these features.

In construction, stainless steel mesh is used for reinforcing concrete. It adds strength and stability, making structures safer. Its non-reactive surface is also vital in food processing. The mesh prevents contamination while allowing for easy cleaning. A study found that stainless steel significantly reduces bacterial growth compared to other materials. This is crucial for health and safety standards in the industry.

However, the cost of stainless steel wire mesh can be higher than alternatives. Some may question its value in low-budget projects. It's essential to weigh initial costs against long-term benefits. Stainless steel's resistance to rust and wear often justifies the investment. Yet, each project has unique needs, and sometimes other materials may suffice. Balancing cost, durability, and application is key to wise decisions.

Comparison of Stainless Steel Wire Mesh with Other Materials

When considering materials for construction or manufacturing, stainless steel wire mesh is often favored. Compared to alternatives like plastic or aluminum, it offers superior strength and durability. According to industry reports, stainless steel mesh can withstand high temperatures up to 1,500 degrees Fahrenheit, significantly better than plastic options. This makes it ideal for demanding applications.

Durability is another key factor. Stainless steel is resistant to corrosion and oxidation, which can be a serious issue for projects exposed to moisture. Research shows that stainless steel can last over 50 years without significant wear. In contrast, aluminum tends to degrade faster under harsh conditions. However, it is more lightweight, which some may find beneficial. This trade-off raises questions: Is lightweight worth the sacrifice in longevity?

Cost considerations also come into play. Stainless steel may have a higher initial investment than aluminum or plastic. Market data indicates that stainless steel wire mesh costs approximately 30% more than aluminum mesh. Yet, the long-term savings from durability and reduced replacement needs could outweigh this initial cost. Therefore, evaluating the right material requires careful thought.

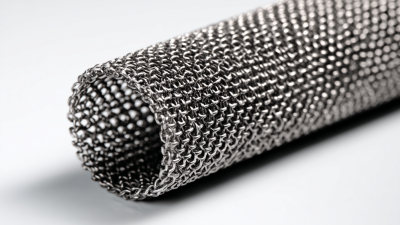

Durability and Corrosion Resistance of Stainless Steel Wire Mesh

Stainless steel wire mesh stands out in a variety of applications due to its exceptional durability and corrosion resistance. According to industry reports, stainless steel can resist oxidation better than other metals, ensuring longevity in harsh environments. This resilience makes it ideal for industries such as construction and food processing, where hygiene is critical.

One study highlighted that stainless steel mesh retains its mechanical properties even at high temperatures. The average lifespan of stainless steel wire mesh can exceed 15 years, significantly reducing replacement costs. In contrast, other materials like plastic or carbon steel often show degradation after only a few years of service.

Tips: When selecting mesh, check the grade of stainless steel. Higher nickel content boosts corrosion resistance. Remember, not all stainless steel is the same.

Pay attention to maintenance as well. Simple cleaning can prolong its lifespan. However, neglect may lead to rust over time, especially if the mesh is not properly sealed. Understanding these nuances can greatly impact project success.

Why Choose Stainless Steel Wire Mesh for Your Projects?

Stainless steel wire mesh stands out due to its exceptional durability and corrosion resistance, making it ideal for various applications. This chart illustrates its performance ratings in key areas, emphasizing the significant advantages it holds over other materials.

Cost-Effectiveness of Stainless Steel Wire Mesh for Long-Term Projects

When it comes to choosing materials for long-term projects, stainless steel wire mesh stands out. Its durability and resistance to corrosion make it a top choice. According to industry reports, it is estimated that stainless steel wire mesh can last over 50 years in harsh environments. This long lifespan translates to significant cost savings over time.

In addition, the initial investment in stainless steel wire mesh can be higher than alternatives. However, its longevity reduces the need for frequent replacements. This makes it more cost-effective for projects that require durability and reliability. A study found that stainless steel can save up to 30% in maintenance costs compared to other materials.

**Tips:** Always consider the environment where the mesh will be used. Stainless steel’s resistance to rust makes it ideal for humid areas. Additionally, evaluate the mesh size based on the project's specific needs. This can further optimize performance and minimize costs over time. Remember, choosing the right material initially can prevent future headaches.

Why Choose Stainless Steel Wire Mesh for Your Projects?

| Project Type | Usage Scenario | Cost per Square Foot | Durability (Years) | Corrosion Resistance |

|---|---|---|---|---|

| Construction | Reinforcement for concrete | $2.50 | 50+ | Excellent |

| Food Processing | Filtration and safety screens | $3.00 | 30+ | Excellent |

| Agriculture | Livestock fencing | $1.75 | 20+ | Good |

| Architecture | Decorative railings | $4.00 | 40+ | Excellent |

Applications and Industries Utilizing Stainless Steel Wire Mesh

Stainless steel wire mesh is widely used in various industries. Its durability and resistance to corrosion make it a preferred material. In construction, it reinforces concrete structures and improves safety. Many architects appreciate its sleek look for modern designs.

Food processing relies on stainless steel wire mesh for hygiene and durability. It can filter and sort materials effectively. Similarly, the automotive industry uses it in manufacturing parts. Mesh provides strength while reducing weight, which is beneficial for efficiency.

The aerospace sector also benefits from this versatile material. Stainless steel wire mesh components enhance safety and performance. However, not all projects may require this level of durability. In some cases, alternatives could be more cost-effective. Considering specific needs is essential when selecting materials.

Related Posts

-

Exploring the Versatility of Stainless Steel Mesh in Modern Applications

-

Why Use Fine Metal Mesh Screen for Effective Filtration Solutions

-

Top 10 Tips for Choosing the Right Stainless Steel Mesh Screen for Your Needs

-

10 Essential Tips for Choosing the Right Aluminum Mesh for Your Project?

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Stainless Mesh for Your Specific Applications