How to Choose the Right Wire and Cable for Your Electrical Projects

Choosing the right wire & cable for your electrical projects is crucial for ensuring safety, performance, and efficiency. According to the International Electrotechnical Commission (IEC), improper selection can lead to electrical failures and pose significant hazards, with industry reports indicating that nearly 30% of electrical incidents are linked to inadequate wiring.

Additionally, the North American Wire & Cable Association projects that the demand for quality wire & cable will increase in tandem with the growth of renewable energy and electric vehicles, emphasizing the need for careful selection criteria. Factors such as material, insulation type, and ampacity ratings play a vital role in determining the suitability of wire & cable for specific applications.

By understanding these elements, engineers and DIY enthusiasts alike can make informed decisions that enhance the longevity and reliability of their electrical systems.

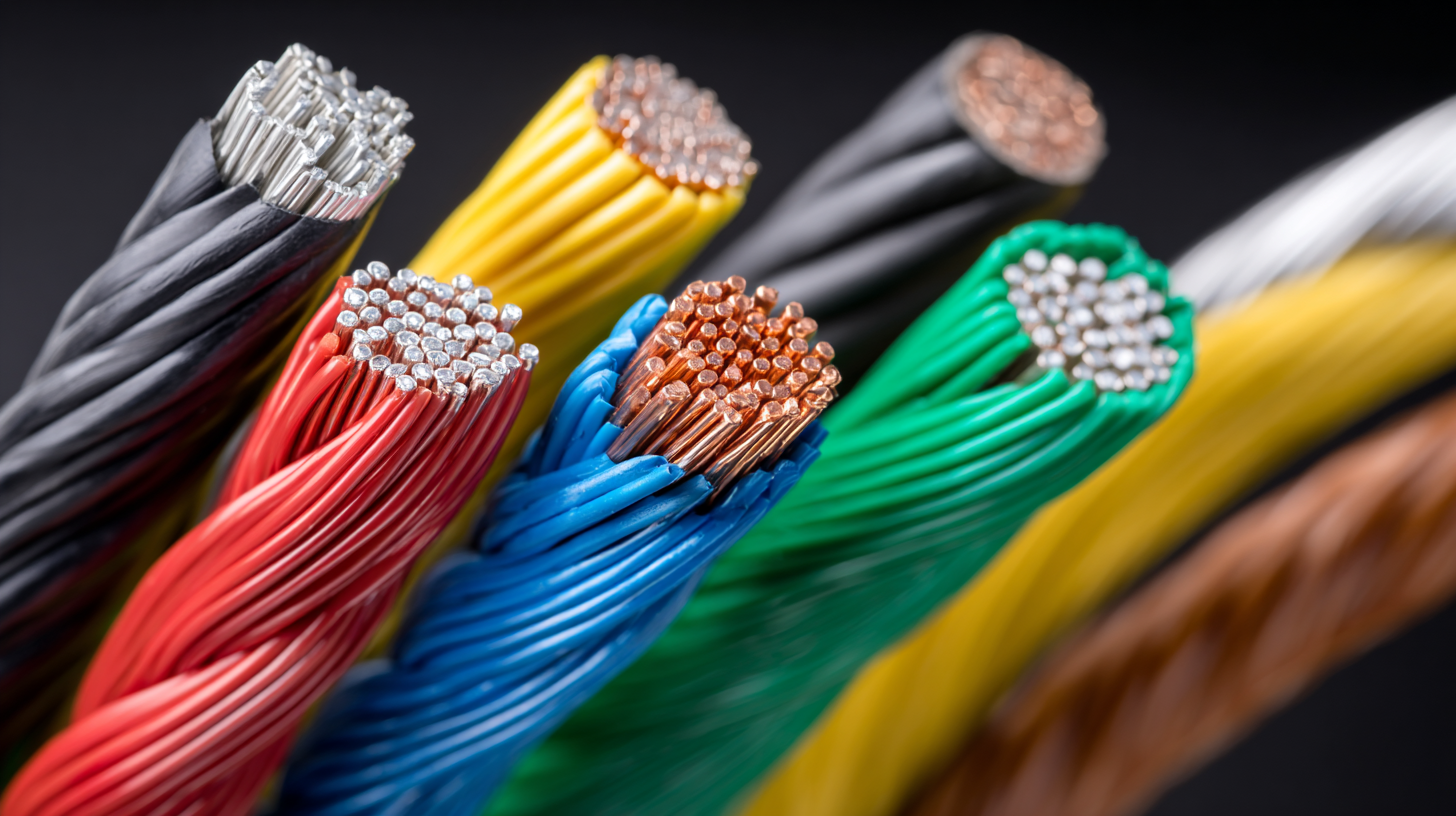

Understanding Different Types of Wires and Cables for Electrical Use

When undertaking electrical projects, understanding the different types of wires and cables available is essential for ensuring safety and efficiency. Various wire and cable types serve distinct purposes, from conducting electricity to offering protection against environmental factors. For instance, fire-resistant cables are specifically designed with materials that inhibit flame spread, making them crucial for installations in high-risk areas.

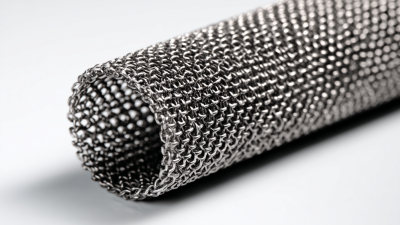

Meanwhile, armored cables provide mechanical protection, which is vital for outdoor or industrial applications, where durability against physical damage is a must.

Meanwhile, armored cables provide mechanical protection, which is vital for outdoor or industrial applications, where durability against physical damage is a must.

Renewable energy is driving innovation in wire and cable development, with an increasing emphasis on efficiency and sustainability. As the demand for renewable energy sources like solar and wind grows, the need for specialized cables that can handle higher voltages and environmental conditions also rises. Additionally, advancements in materials—such as bioengineered compounds—are being explored, including discoveries of microorganisms that could lead to new bioelectric technologies. Understanding these evolving options allows electrical professionals to make informed choices that align with both functional requirements and sustainable practices.

Evaluating Electrical Specifications and Ratings for Your Project Needs

When selecting the appropriate wire and cable for your electrical projects, understanding the electrical specifications and ratings is crucial. First, consider the ampacity, which refers to the maximum current a wire can safely carry. This is influenced by factors such as wire gauge, insulation type, and ambient temperature. For instance, a thinner wire may be suitable for low-load applications, while thicker wire is necessary for high-load scenarios. Always refer to the National Electrical Code (NEC) guidelines to ensure compliance with safety standards.

Additionally, evaluating the voltage rating is essential to prevent breakdowns and potential hazards. Different cables are designed to handle specific voltage levels, and using a wire rated for lower voltage in a higher voltage application can lead to insulation failure. Moreover, consider the environment where the wire will be installed—wires exposed to moisture may require waterproof insulation, while those in high-heat areas may need special heat-resistant materials. By carefully assessing these specifications, you can choose the right wire and cable that ensures both safety and efficiency for your electrical projects.

Wire and Cable Selection for Electrical Projects

This chart provides a comparison of different types of wire and cable specifications, including current rating (in Amps), voltage rating (in Volts), and wire gauge (in AWG). This data will help you choose the right wire and cable for your electrical projects based on your specific needs.

Choosing the Right Gauge for Safety and Efficiency in Wiring

Choosing the right gauge for wire and cable is crucial for ensuring both safety and efficiency in electrical projects. The wire gauge, which is a measure of the wire's diameter, directly affects how much electrical current can safely pass through it. Typically, the American Wire Gauge (AWG) system is used, where a lower gauge number indicates a thicker wire with a higher current-carrying capacity. For example, a 12-gauge wire can handle more current than a 14-gauge wire, making it essential to select the appropriate gauge based on the project's electrical load requirements.

In addition to current capacity, other factors such as the length of the wire run and the environment in which the wire will be used should also be taken into account. Longer runs may necessitate a larger gauge to compensate for voltage drop, while specific locations may require wires that are resistant to moisture or extreme temperatures. By carefully evaluating these aspects, you can ensure that the wire gauge chosen not only meets safety standards but also enhances the overall performance and reliability of your electrical system. This thoughtful approach is key to avoiding potential hazards and maximizing the efficiency of electrical installations.

Identifying Environmental Factors Affecting Wire Selection

When selecting the appropriate wire and cable for electrical projects, identifying environmental factors is crucial. Elements such as temperature, humidity, exposure to chemicals, and UV radiation can significantly influence wire performance and lifespan. According to a report from the National Electrical Manufacturers Association (NEMA), wires exposed to extreme temperatures can lose up to 30% of their rated capacity, leading to overheating and potential failure.

Tips: Always check the manufacturer's specifications for temperature ratings and suitability for your specific environmental conditions.

Furthermore, installations in wet or corrosive environments require special consideration. Choosing cables with adequate insulation and those rated for moisture resistance, such as those meeting the IEC 60529 standard for ingress protection, is essential. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that cables used in marine applications must withstand saltwater corrosion, which can drastically shorten their lifespan if not properly rated.

Tips: For outdoor applications, opt for UV-resistant cables to prevent degradation over time. Additionally, consider using conduit or protective sheathing for added security against harsh conditions.

Assessing Cost and Quality When Sourcing Electrical Wires and Cables

When sourcing electrical wires and cables for your projects, assessing cost and quality is crucial. Quality should be prioritized, as inferior products can lead to severe safety hazards and performance issues. Look for wires and cables that meet industry standards, such as those certified by organizations like UL or IEC. These certifications ensure that the materials used are durable and reliable, providing peace of mind in your electrical installations.

Cost is another important factor, but it should not compromise quality. It is wise to compare prices from multiple suppliers while considering the long-term value of the products. Cheaper options may save money upfront but could lead to higher costs over time due to failures or the need for replacements. Balancing cost with quality ensures that your electrical projects are not only economically viable but also safe and efficient. Always ask suppliers for detailed information about the materials and workmanship involved to make an informed decision that supports the integrity of your work.