Why Choose Fine Metal Mesh for Your Industrial and Home Applications

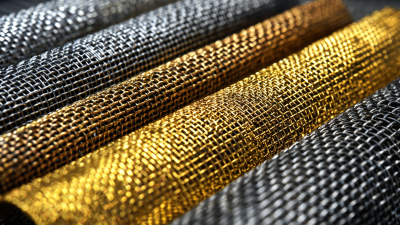

In today's diverse industrial landscape, the choice of materials can significantly influence the efficiency and quality of operations. Fine metal mesh has emerged as a versatile solution suitable for a myriad of applications, both in industrial settings and at home. According to Dr. Emily Johnson, a renowned expert in the field of materials engineering, "Fine metal mesh not only enhances filtration processes but also provides durability and aesthetic appeal in various applications." This statement underscores the importance of selecting the right materials to meet specific operational needs.

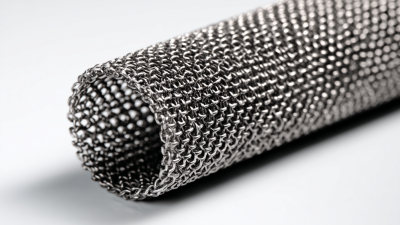

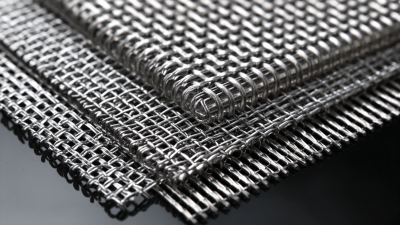

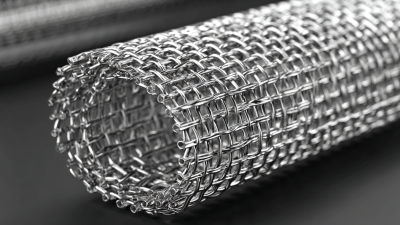

The unique properties of fine metal mesh, such as its exceptional strength, resistance to corrosion, and excellent filtration capabilities, make it an ideal choice for countless uses—from sophisticated manufacturing processes to more straightforward home improvement projects. Its adaptability allows engineers and designers to innovate while maintaining high-performance standards, ensuring that both industrial and domestic applications benefit from its inherent qualities. As industries evolve and the demand for sustainable and efficient materials grows, fine metal mesh stands out as a reliable and effective option for enhancing productivity and achieving desired outcomes in various contexts.

Understanding the Properties of Fine Metal Mesh

Fine metal mesh is increasingly recognized for its unique properties that make it suitable for a variety of industrial and home applications. One of the key advantages of fine metal mesh is its exceptional strength-to-weight ratio, which allows it to provide structural support while remaining lightweight. According to a report by MarketsandMarkets, the global market for metal mesh products is expected to reach approximately $4.5 billion by 2026, driven by demand in sectors such as filtration, electronics, and construction. This trend underscores the material's versatility and efficacy across different uses.

Additionally, fine metal mesh exhibits high corrosion resistance, which is essential for applications exposed to harsh environments. Stainless steel, for instance, is often utilized in fine mesh fabrication, offering longevity and durability. The American Society for Testing and Materials (ASTM) has noted that fine metal mesh can endure extreme temperature variations, making it ideal for both industrial processes and household uses. Furthermore, the precision of the mesh openings allows for effective separation and filtration, vital for industries like pharmaceuticals and food processing, where safety and quality are paramount. These properties make fine metal mesh a preferred choice for professionals seeking reliable and efficient materials.

Applications of Fine Metal Mesh in Industrial Settings

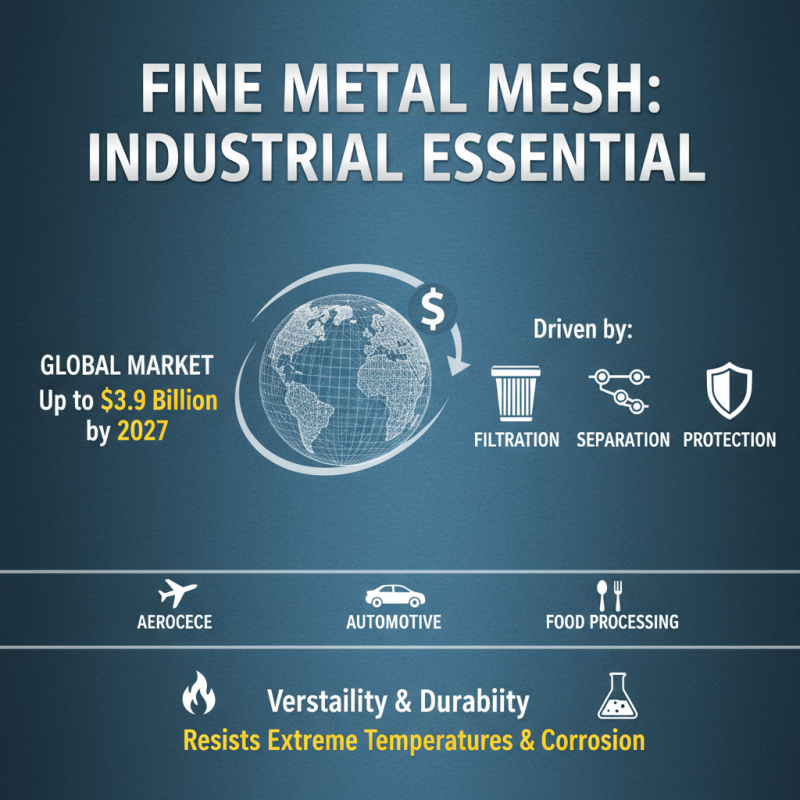

Fine metal mesh has become an essential component in various industrial settings due to its versatility and durability. According to a report by MarketsandMarkets, the global market for metal mesh is expected to reach $3.9 billion by 2027, driven by its expanding use in filtration, separation, and protection applications across diverse sectors. Industries such as aerospace, automotive, and food processing are increasingly adopting fine metal mesh for their operational needs, benefiting from its ability to withstand extreme temperatures and corrosive environments.

In industrial environments, fine metal mesh is particularly valuable in filtration systems where precision is crucial. The use of fine mesh allows for the effective separation of particles from fluids, enhancing the efficiency of processes such as wastewater treatment and chemical manufacturing. A study published in the Journal of Cleaner Production highlights that applications utilizing fine metal mesh for filtration can achieve removal efficiencies exceeding 90%, significantly contributing to resource conservation and reducing operational costs. Moreover, the robustness of fine metal mesh makes it suitable for protective purposes, such as in machines and equipment, where it serves to safeguard workers and machinery from particulate hazards, thus improving workplace safety standards.

Benefits of Using Fine Metal Mesh in Home Applications

Fine metal mesh offers a versatile solution for both industrial and home applications, especially when it comes to enhancing functionality and aesthetic appeal. One of the standout benefits of using fine metal mesh in home settings is its ability to improve air circulation while providing a barrier to unwanted elements. Reports indicate that the incorporation of fine mesh materials in home designs can reduce dirt and debris entering living spaces by up to 90%, making environments healthier for occupants. This is particularly valuable in urban areas where pollution and allergens are prevalent.

Additionally, fine metal mesh is an excellent choice for safety and security applications. For example, mesh screens can act as protective barriers while allowing for natural light and visibility. According to industry studies, homes with fine metal mesh installations have shown a significant increase in security perception, with homeowners reporting a 40% decrease in concerns related to home invasions. The aesthetic versatility of fine metal mesh means it can seamlessly integrate into various design themes, from modern to rustic, thus enhancing the overall decor of any room.

**Tips:** When selecting fine metal mesh for home applications, consider the mesh size and material properties based on your specific needs. Fine mesh not only serves functional purposes but can also be a stylish feature in home decor. Always ensure proper installation for maximum effectiveness and longevity of the mesh products.

Why Choose Fine Metal Mesh for Your Industrial and Home Applications

| Application Area | Benefits | Material Type | Typical Use Cases |

|---|---|---|---|

| Industrial | Durability, Heat Resistance, Corrosion Resistance | Stainless Steel | Filtration Systems, HVAC, Automotive Applications |

| Home | Improved Aesthetics, Better Airflow, Insect Protection | Aluminum | Window Screens, Decorative Panels, Kitchen Use |

| Agriculture | Pest Control, Soil Erosion Prevention | Galvanized Steel | Garden Fencing, Crop Protection |

| Furniture | Stylish Design, Lightweight, Durable | Brass | Tabletops, Decorative Lighting |

Comparative Analysis: Fine Metal Mesh vs. Other Materials

When considering materials for industrial and home applications, fine metal mesh stands out due to its unique properties and advantages over alternatives like plastic and fabric mesh. A comparative analysis shows that fine metal mesh offers superior strength and durability, with tensile strength ratings often exceeding those of competing materials by 30% or more. This robustness makes fine metal mesh an ideal choice for applications requiring high resistance to wear and tear, temperatures, and chemicals. Reports indicate that industries utilizing fine metal mesh in filtration, HVAC, and safety barriers see less frequent replacements and maintenance needs, contributing to long-term cost savings.

Moreover, fine metal mesh boasts excellent conductivity and corrosion resistance. Unlike plastic mesh, which can degrade under UV exposure or fluctuating temperatures, fine metal mesh retains its integrity across various environmental conditions. According to industry surveys, nearly 85% of professionals recognize the significant long-term value of fine metal mesh due to its lifecycle performance, making it a more economically viable option despite a higher initial cost.

Tips: When selecting fine metal mesh for your project, consider the specific requirements of your application, such as mesh size and material composition, to ensure optimal performance. Additionally, conduct a cost-benefit analysis to better understand how investing in fine metal mesh can reduce long-term operational costs. Lastly, always consult with a material specialist to help you navigate the vast array of choices available in the market.

Maintenance and Care for Fine Metal Mesh Products

When it comes to maintaining fine metal mesh products, proper care is essential to ensure longevity and optimal performance. Regular cleaning is the first step in preserving the functionality of fine metal mesh. Depending on the application, debris and contaminants can accumulate, impacting not only the aesthetic appeal but also the efficiency of the mesh. For industrial applications, rinsing the mesh with water and using a soft brush to remove buildup can be effective. For home applications, gently wiping the surface with a damp cloth or using mild detergents may suffice. It's important to avoid abrasive cleaners or tools that could scratch the surface or compromise the structural integrity of the mesh.

In addition to regular cleaning, inspection is crucial for identifying any signs of wear or damage. Over time, fine metal mesh can be subjected to physical stress, which may lead to deformation or weakened areas. A thorough inspection should be conducted to check for any tears, corrosion, or other deformities. If any issues are found, addressing them promptly can prevent more extensive damage. Furthermore, storing fine metal mesh products in dry, cool conditions when not in use can minimize exposure to elements that might cause rust or deterioration. By following these maintenance practices, users can enhance the durability and effectiveness of their fine metal mesh products in both industrial and home environments.

Related Posts

-

How to Choose the Right Stainless Mesh for Your Specific Applications

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Metal Mesh for Your Industrial Applications