How to Choose the Best Wire Mesh Products for Your Project Needs

When embarking on a new project, one of the critical elements to consider is the selection of appropriate materials, particularly wire mesh products. These versatile components play a significant role in various applications, from construction and landscaping to industrial usage and art installations. Given the wide array of options available in the market today, it can be overwhelming to identify which wire mesh products best suit your specific project needs.

In this guide, we will explore the essential factors that influence your choice of wire mesh products. We will delve into the various types, sizes, and materials available, ensuring that you are equipped with all the necessary knowledge to make an informed decision. Understanding the specific requirements of your project will ultimately lead you to the most suitable wire mesh products, enhancing both functionality and durability in your work. By the end, you will have a clearer vision of how to navigate the market and select items that align with your unique goals and preferences.

Understanding Different Types of Wire Mesh and Their Applications

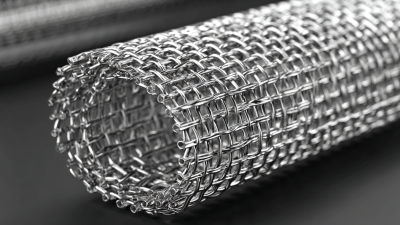

When selecting wire mesh products for your project, it is essential to understand the various types available and their specific applications. Wire mesh can be categorized primarily into welded, woven, and expanded types. Welded wire mesh consists of wire strands that are electrically welded at intersections, providing excellent strength and stability, making it ideal for fencing, reinforcement in concrete, and agricultural applications. Its uniformity and durability make it a preferred choice for many construction projects.

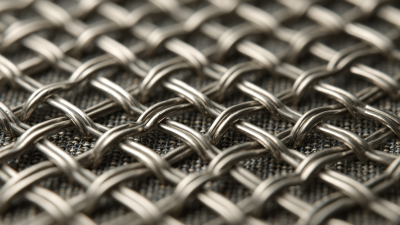

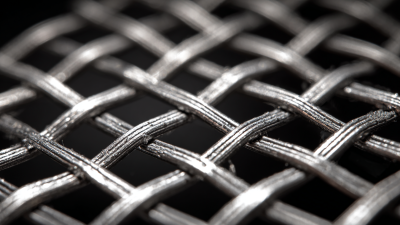

On the other hand, woven wire mesh is created by interlacing wires in a pattern that can vary in tightness and openness. This type is often used in industrial applications such as filtration, safety screens, and even decorative elements in architecture. The versatility of woven wire mesh allows for a range of sizes and mesh configurations tailored to specific needs. Lastly, expanded metal mesh is formed by slitting and stretching metal sheets, resulting in a lightweight yet strong material. This type is commonly used for walkways, security enclosures, and as a protective barrier, providing both functionality and aesthetic appeal. Understanding these distinctions will guide you in selecting the best wire mesh product to meet your project's demands.

Key Factors to Consider When Selecting Wire Mesh Products

When selecting wire mesh products, there are several key factors that should influence your decision. Firstly, the material of the wire mesh is crucial. Options such as steel, aluminum, and stainless steel each have unique properties that affect durability, corrosion resistance, and overall performance. According to a report by IMARC Group, the wire mesh fencing manufacturing industry is expected to see substantial growth, and understanding material characteristics can help ensure you select the right type for your specific project needs.

Another critical consideration is the wire mesh's specifications, such as mesh size and wire diameter. These factors determine the product's strength and application suitability. For instance, smaller mesh sizes might be ideal for applications requiring improved security, while larger openings could be more appropriate for filtration processes. Additionally, market analysis indicates that consumer preferences are shifting towards environmentally friendly options, and this trend influences the materials and manufacturing processes used in wire mesh production. Selecting products that align with sustainability goals can not only enhance your project but also appeal to environmentally-conscious consumers.

Top 5 Wire Mesh Brands for 2025: Features and Benefits

When selecting wire mesh products for your project, the brand can significantly impact quality and performance. As we move into 2025, five brands stand out for their exceptional features and benefits. Firstly, Welded Wire Mesh by WireCrafters offers unparalleled strength, making it ideal for industrial applications. According to a report by Grand View Research, the demand for welded wire mesh is expected to grow by 5% annually, driven by its widespread use in construction and security sectors.

Another top contender is McNICHOLS, renowned for its diverse range of wire mesh styles, including decorative options that cater to architects and designers. Their products are praised for their durability and aesthetic appeal, with industry analysts noting a notable increase in architectural projects utilizing custom wire mesh. Additionally, Fleischer Wire Products provides corrosion-resistant wire mesh, crucial for outdoor or marine applications. Market data indicates a growing preference for such materials, aligning with sustainability trends as more businesses seek eco-friendly solutions in their projects.

Lastly, the innovative designs of Wire Mesh Corporation have garnered attention for improving airflow and visibility without compromising strength. As the wire mesh market evolves, focusing on these leading brands can ensure that your project not only meets industry standards but also benefits from advanced technology and materials.

How to Choose the Best Wire Mesh Products for Your Project Needs - Top 5 Wire Mesh Brands for 2025: Features and Benefits

| Wire Mesh Type | Material | Mesh Size | Uses | Benefits |

|---|---|---|---|---|

| Welded Wire Mesh | Steel | 1/2 inch | Fencing, Animal Enclosures | Strong, Durable, Versatile |

| Expanded Metal | Aluminum | Diamond Pattern | Grilles, Walkways | Lightweight, Rust-Resistant |

| Chain Link Fencing | Steel | 2 inch | Perimeters, Gardens | Cost-Effective, Easy Installation |

| Stainless Steel Wire Mesh | Stainless Steel | 1/4 inch | Filters, Screens | Corrosion-Resistant, Long-Lasting |

| Copper Wire Mesh | Copper | 1/8 inch | Electromagnetic Shielding | Good Conductor, Non-Magnetic |

Cost vs. Quality: Finding the Right Balance in Wire Mesh Selection

When selecting wire mesh products for a project, balancing cost and quality is crucial. While budget constraints often drive purchasing decisions, compromising too much on quality can lead to issues down the line. High-quality wire mesh not only enhances the durability and effectiveness of your project but can also minimize the need for future replacements or repairs. Investing in superior materials may seem costly upfront, but it can save you money and hassle in the long run.

On the other hand, there are affordable options that can meet project specifications without sacrificing performance. It's essential to assess the specific requirements of your project—consider factors like load-bearing capacity, environmental conditions, and the intended use of the wire mesh. By carefully evaluating both your budget and the long-term benefits of different wire mesh options, you can find a balance that satisfies your project's needs without compromising on quality. Choosing the right wire mesh involves not just looking at immediate costs but also considering the overall value and longevity of the product.

Sustainability in Wire Mesh Production: Choosing Eco-Friendly Options

When selecting wire mesh products for your project, considering sustainability can significantly impact both the environment and the quality of your choice. Eco-friendly wire mesh options are produced using sustainable practices that minimize environmental footprints. Look for products made from recycled materials, which not only reduce waste but also conserve natural resources. Additionally, consider manufacturers that adhere to eco-friendly processes, ensuring that the production methods are energy-efficient and produce minimal pollution.

Tips: When evaluating wire mesh options, research the lifecycle of the materials used. Opt for meshes that are durable and recyclable, which can lessen waste and extend the product's usability. Always request information on the sourcing of materials and be wary of those that don't clearly outline their sustainability commitments.

Another crucial aspect to consider is the chemical treatments used in wire mesh production. Selecting untreated or naturally treated products can further mitigate environmental impact. By prioritizing eco-friendly wire mesh, you're not just supporting sustainable practices; you’re also investing in quality materials that contribute to a healthier planet.

Related Posts

-

How to Choose the Right Wire Mesh Products for Your Project Needs

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

Understanding the Versatility of SS Wire Mesh: Applications and Benefits in Modern Industries