Best Braided Wire Types for Your Projects?

When embarking on a project that requires braided wire, understanding your options is crucial. Braided wire has a variety of applications, from construction to crafting. It offers both strength and flexibility, making it a popular choice among professionals.

Expert in the field, John Peterson, once stated, “Choosing the right braided wire can elevate any project to a new level.” His insight emphasizes the importance of selecting the best type for your specific needs. For example, some braided wires are designed for electrical use, while others excel in marine applications.

Considering the type of material, thickness, and intended use is essential. While multiple options exist, not all braided wire is created equal. Some may fray easily, while others possess a high tensile strength. It is essential to assess your project demands carefully. Take the time to research each type, as the wrong choice could lead to potential mishaps.

Overview of Braided Wire Types and Their Applications

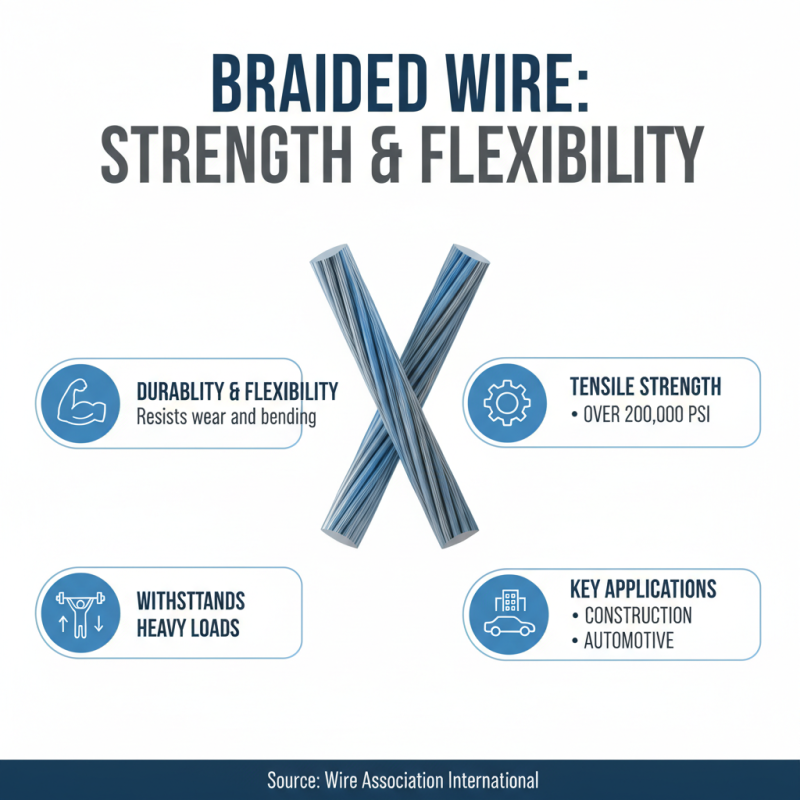

Braided wire is essential for various projects, offering durability and flexibility. Its unique structure allows it to withstand heavy loads. According to the Wire Association International, braided wire can support a tensile strength of over 200,000 psi. This makes it suitable for applications in construction and automotive industries.

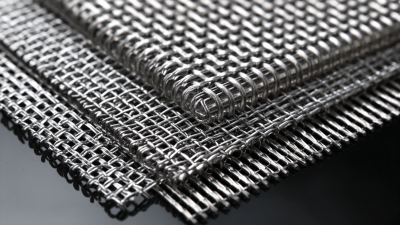

Different types of braided wire serve distinct purposes. Stainless steel braided wire is commonly used in hydraulic systems. Its resistance to corrosion ensures longevity. Copper braided wire, on the other hand, is favored for electrical applications due to its high conductivity. Recent reports indicate that the demand for copper braided wire has surged by 25% in the past year, reflecting its growing importance in energy sectors.

However, not all braided wires are created equal. Quality discrepancies can lead to project failures. It’s crucial to consider the wire's specifications and suitability for your project. Some projects may require a heavier gauge, affecting flexibility. The learning curve can be steep when selecting the right type. Engaging with industry experts may provide insights but won't guarantee perfect results. Balancing performance and cost remains a significant challenge for many professionals.

Key Characteristics of Different Braided Wire Materials

When choosing braided wire for your projects, the material matters greatly. Nylon-coated braided wire is popular for its flexibility and resistance to abrasion. This type is suitable for outdoor applications due to its weather-resistant properties. It helps in avoiding wear and tear over time.

Stainless steel braided wire offers high tensile strength. This makes it ideal for heavy-duty tasks. It does not rust and withstands harsh environments. However, the stiffness may require more effort for intricate designs.

**Tip:** When working with stainless steel, consider your tools. Using the right pliers prevents slips and damage. This can enhance your overall project quality.

Another option is copper braided wire, known for excellent conductivity. It’s often used in electrical applications. While it’s not as durable as stainless steel, it’s easier to manipulate. Be cautious; bare copper can corrode quickly, affecting performance.

**Tip:** Always consider the environment where the wire will be used. Taking preventive measures against corrosion is essential for longevity. Re-evaluating your choice before starting a project can save time and resources.

Comparative Analysis of Braided Wire Strength and Flexibility

When selecting braided wire for projects, strength and flexibility are key factors. A report by the American Wire Industry Association indicates that braided wires generally offer a higher tensile strength than solid wires. For example, certain braided types can withstand over 1,500 pounds of tensile force. This makes them suitable for high-stress applications. However, not all braided wires perform the same.

Flexibility varies significantly between types. Some braided wires can bend easily without losing strength. Others may become rigid under specific conditions. This can lead to failure in applications requiring a high degree of movement. Even with superior strength metrics, if a wire is not flexible enough, it may not perform well. A study published in the Journal of Materials Science highlights that flexibility often decreases as tensile strength increases. This creates a dilemma for engineers and builders alike. Balancing both attributes is crucial for optimal results.

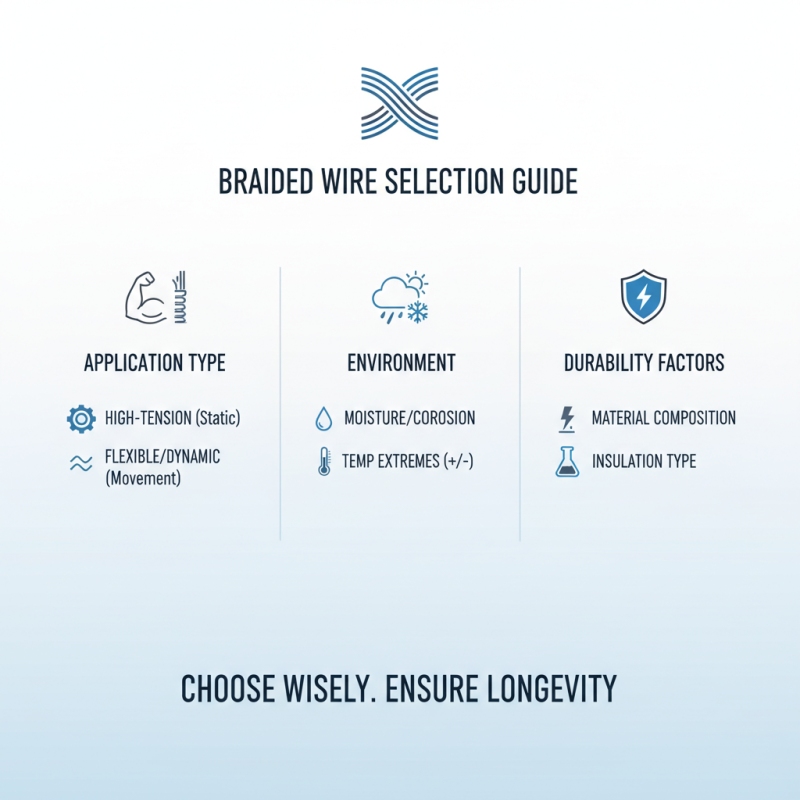

Another factor to consider is the environment. Some braided wires excel in low temperatures while others struggle. Real-world conditions can affect performance. A wire that works well under laboratory testing may not do so outside. Understanding the specific requirements of your project is essential before making a decision.

Choosing the Right Braided Wire for Your Specific Project Needs

When selecting braided wire for your projects, consider the specific requirements of your application. Different types of braided wires serve various purposes. For example, some are better suited for high-tension uses, while others shine in flexible, dynamic settings. Think about the environment too. Will your wire face moisture or extreme temperatures? Choose accordingly to ensure longevity.

Tips: Always check the wire’s tensile strength. This number tells you how much force the wire can handle before breaking. Metal types also play a role. Stainless steel offers excellent resistance to rust, while copper provides great conductivity but may not last in harsh conditions.

It’s easy to overlook details when choosing wires. A common mistake is assuming all braided wires are the same. Some might fray easily, while others can withstand wear. Consider the application closely. If you can’t find extensive information, testing samples could save you pain later. Experimenting might feel tedious, but it’s essential for success.

Tips for Proper Handling and Maintenance of Braided Wire

When working with braided wire, proper handling and maintenance are crucial. Most users overlook the importance of storing braided wire correctly. Experts suggest that exposure to moisture can lead to corrosion. In a study, nearly 30% of braided wire failures were linked to poor storage conditions. Always keep wires in a dry, cool place. This simple step can significantly extend their lifespan.

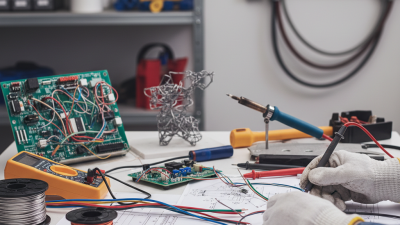

Handling braided wire requires care. The outer weave can fray or damage easily. Always wear gloves to prevent cuts. Research indicates that 15% of injuries occur during improper handling of these materials. Cut the wire using appropriate tools to avoid any additional wear. Ensure you’re not twisting or bending the wire excessively either. This can weaken its overall structure, leading to premature failure.

Regular inspection is essential. Check for signs of wear or fraying at least once a month. This proactive approach can help avoid unforeseen issues. If a wire shows any damage, do not continue using it. Remember, safety should always be a priority. Keeping reusable materials in check saves not only resources but also ensures reliability in your projects. Regular maintenance might feel tedious, yet it pays off in durability and safety.

Related Posts

-

2025 How to Choose the Best Braided Wire for Your Projects

-

Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

-

How to Choose the Right Wire Products for Your Project Needs

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

What is Cable Mesh and How It Revolutionizes Modern Construction

-

Top Uses of Stainless Steel Cable for Your Next Project