Understanding the Benefits of Woven Stainless Steel Mesh in Modern Applications

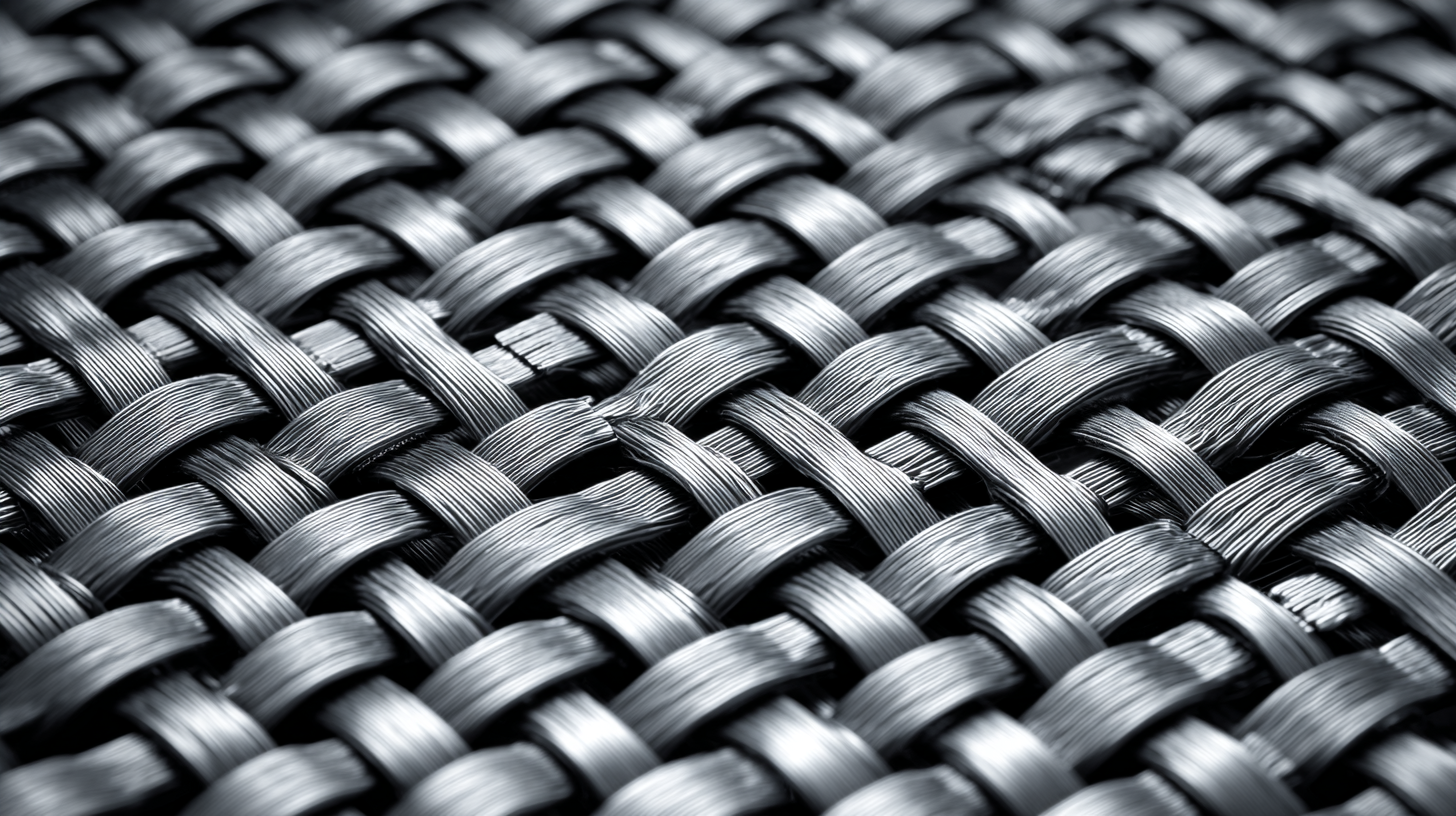

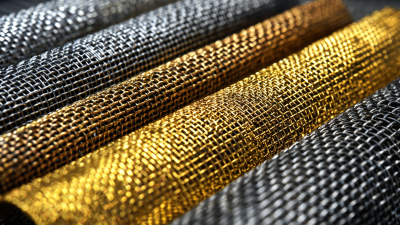

In today's advanced industrial landscape, the significance of material selection cannot be overstated, particularly when it comes to enhancing functionality and durability. Woven stainless steel mesh has emerged as a versatile solution across various modern applications, thanks to its unique combination of strength, corrosion resistance, and flexibility. This mesh offers not only structural integrity but also aesthetic appeal, making it ideal for use in sectors such as architecture, automotive, and filtration. Understanding how to effectively utilize woven stainless steel mesh can lead to improved product performance, longevity, and safety in manufacturing processes. This article aims to explore the numerous benefits of woven stainless steel mesh, providing insights into its diverse applications and practical tips for implementation in your projects. By the end, you will appreciate why this innovative material is increasingly preferred by engineers and designers alike.

Advantages of Woven Stainless Steel Mesh in Industrial Settings

Woven stainless steel mesh has become a crucial component in various industrial settings due to its unique advantages. As highlighted in recent market research, the global woven wire mesh market, valued at approximately USD 2.98 billion in 2024, is projected to grow to USD 4.06 billion by 2033. This significant growth reflects the increasing demand for durable and versatile materials across diverse sectors, including construction, manufacturing, and filtration.

One of the primary benefits of woven stainless steel mesh is its exceptional strength and durability. This material can withstand high-temperature environments and harsh chemicals, making it ideal for applications such as industrial filters and safety barriers. Additionally, its woven structure allows for superior airflow and minimal resistance, which is essential in applications like HVAC systems and water treatment processes.

**Tips:** When selecting woven stainless steel mesh for your project, consider the specific mesh configuration and open area percentage to ensure optimal performance. Regular maintenance and cleaning can also extend the lifespan of the mesh in corrosive environments. Furthermore, understanding the mesh's tensile strength will help in evaluating its suitability for heavy-duty applications.

Applications of Woven Stainless Steel Mesh in Filtration Systems

Woven stainless steel mesh has become a critical component in various filtration systems across multiple industries, owing to its unparalleled durability and efficacy. With its exceptional resistance to corrosion and heat, woven stainless steel mesh is widely utilized in water treatment facilities, chemical processing, and food and beverage industries. According to a recent market research report by Allied Market Research, the global stainless steel mesh market is projected to reach USD 2.5 billion by 2026, indicating a significant growth driven by increasing demands for filtration solutions.

In filtration systems, woven stainless steel mesh provides precise filtration through varying mesh sizes, effectively trapping particles while allowing adequate flow rates. This adaptability not only enhances performance but also extends the lifespan of filtration equipment. Industry data highlights that the use of stainless steel mesh can improve filtration efficiency by over 40% compared to traditional materials, thereby reducing operational costs and downtime significantly.

Tip: When selecting stainless steel mesh for filtration, consider the mesh size and wire diameter to ensure optimal performance for your specific application. Additionally, regular maintenance and cleaning of the filtration systems can prolong the life of the mesh and improve its filtration capacity.

Durability and Corrosion Resistance of Woven Stainless Steel Mesh

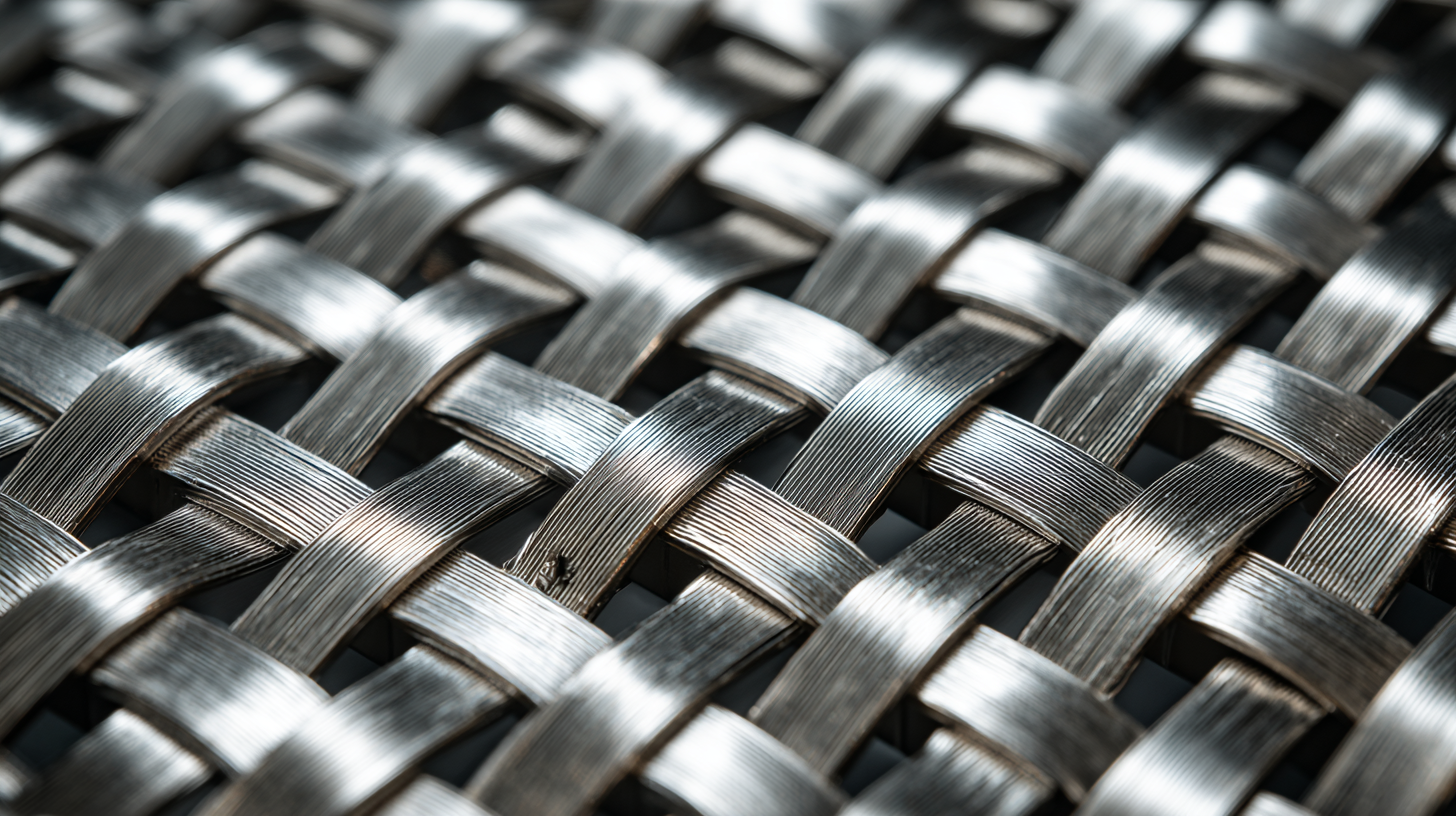

Woven stainless steel mesh is gaining recognition in various industries due to its exceptional durability and corrosion resistance, making it an ideal choice for demanding applications. Studies suggest that stainless-steel wire mesh exhibits superior mechanical properties when reinforced in hybrid composite materials, particularly in aerospace settings. For instance, research indicates that the size of the stainless-steel wire mesh can significantly influence the mechanical performance of glass fiber-reinforced laminates, potentially optimizing structural integrity and longevity under mechanical stresses.

In addition to aerospace, the expanding woven wire mesh market is projected to grow from approximately USD 2.98 billion in 2024 to USD 4.06 billion by 2033, underscoring the increasing demand for materials that combine strength with resistance to environmental factors. The durability of woven stainless steel mesh not only provides enhanced structural capabilities but also ensures that it withstands corrosive environments, thus offering a longer service life. This combination of attributes makes woven stainless steel mesh an invaluable material across various sectors, from construction to specialized applications in bio-inspired technologies.

Cost-Effectiveness of Woven Stainless Steel Mesh in Long-Term Use

Woven stainless steel mesh has emerged as a cost-effective solution in various industries, particularly for long-term applications. Its durability and resistance to environmental factors significantly reduce the frequency of replacements, which is often a major cost driver in material selection. In comparison to other materials, the lifespan of woven stainless steel mesh, coupled with its ability to withstand harsh conditions, offers businesses a reliable option that proves economically advantageous over time.

Moreover, recent advancements in material science, such as the development of superhydrophobic and oleophilic modified stainless steel meshes, enhance their performance in specific applications like filtration and separation. This innovation not only improves efficiency but also minimizes operational costs associated with maintenance and cleaning. The integration of these advanced woven meshes in sectors like aerospace and energy storage, showcasing their versatility and value, underscores a growing trend: selecting materials that provide both high performance and long-term financial benefits.

Comparative Analysis: Woven vs. Other Mesh Materials in Modern Industry

In the realm of modern industry, woven stainless steel mesh presents a significant advantage over alternative mesh materials. Its exceptional durability and resistance to corrosion make it a preferred choice in various applications, especially in environments prone to moisture and chemicals. Compared to traditional materials like aluminum or plastic meshes, woven stainless steel mesh maintains structural integrity under stress and extreme conditions, making it ideal for industries ranging from construction to automotive.

Furthermore, the comparative analysis of woven stainless steel mesh versus other materials highlights its eco-friendly properties, especially in sustainable construction practices. Innovative configurations of steel wire mesh not only enhance the mechanical properties of reinforced concrete structures but also contribute to the overall sustainability of construction projects. As industries increasingly emphasize green initiatives, the adoption of woven stainless steel mesh is poised to rise as it offers both functional performance and environmental benefits, aligning with the global shift toward eco-conscious manufacturing and building strategies.

Related Posts

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

-

How to Choose the Perfect Fireplace Screen for Your Home Decor

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

Exploring Trends in Metal Mesh Supply & Demand at the 2025 China Import and Export Fair: Insights and Data

-

How to Choose the Right Metal Mesh for Your Industrial Applications