Understanding the Benefits of Wire Mesh Filters in Industrial Applications

In today's industrial landscape, the efficiency and reliability of filtration systems play a critical role in maintaining operational standards and product quality.

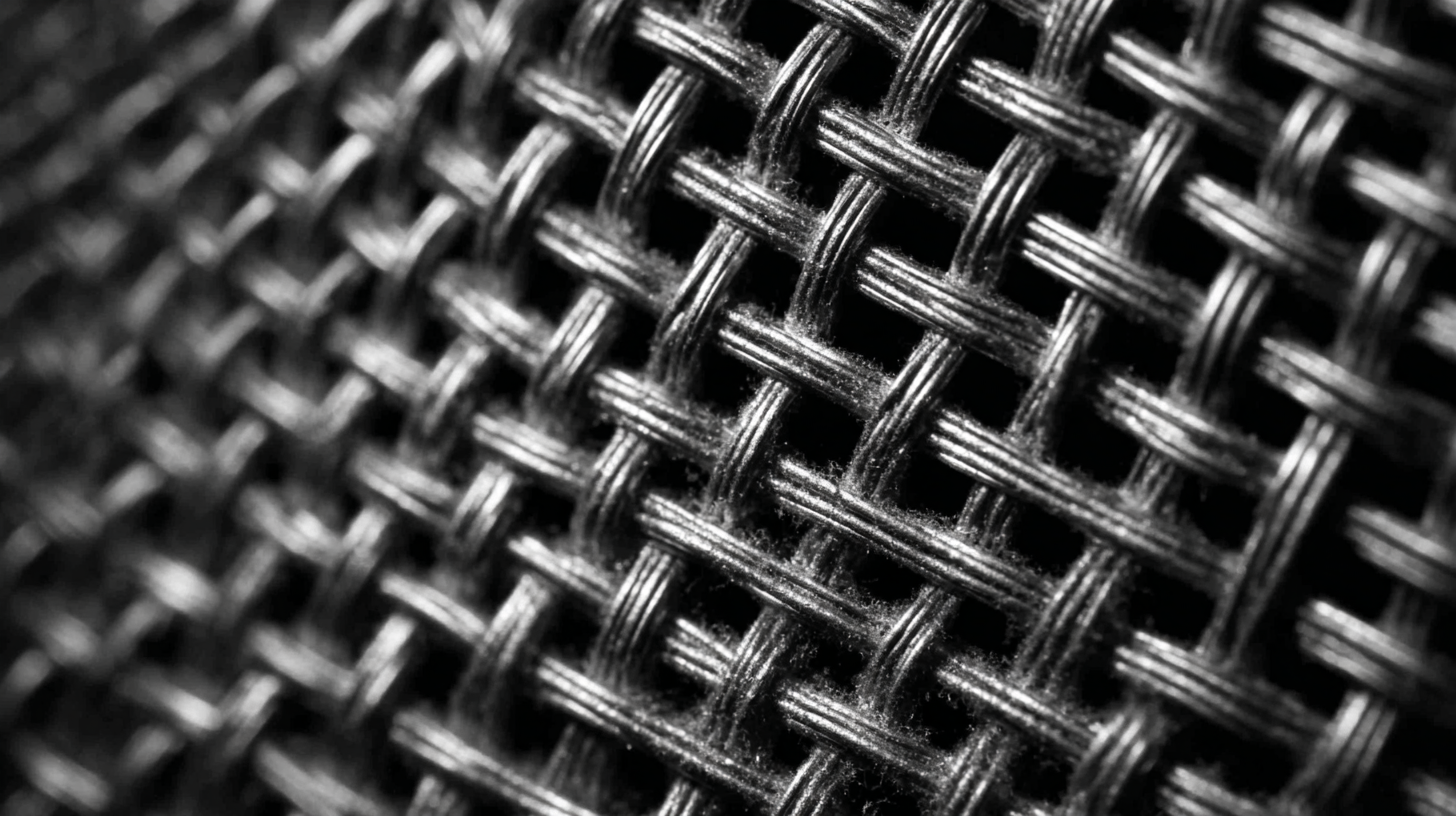

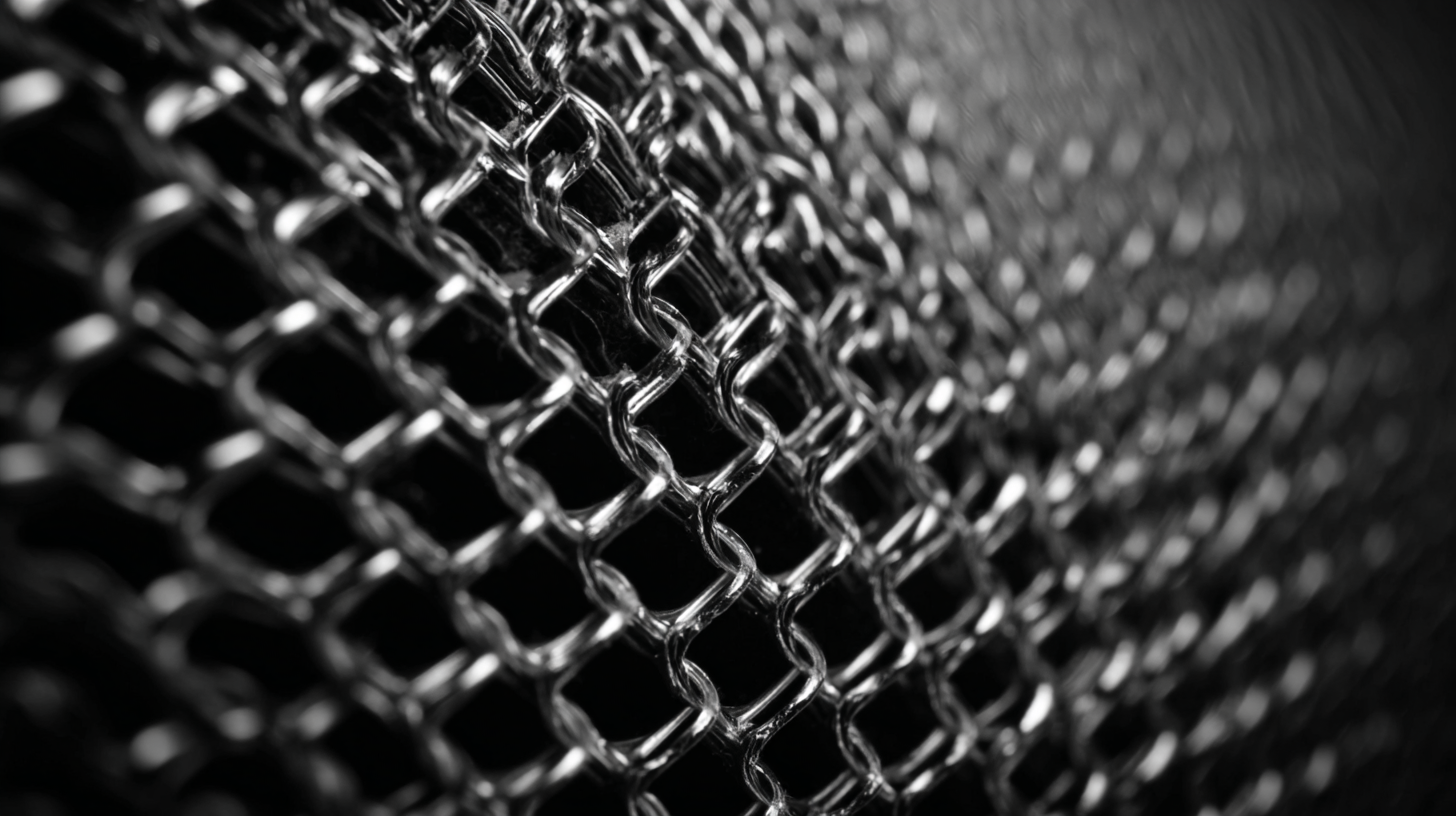

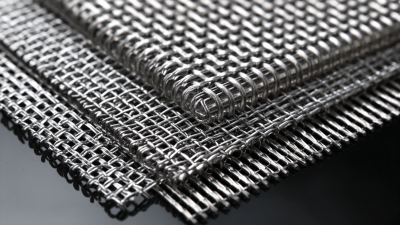

Wire mesh filters have emerged as a vital component in various applications, from chemical processing to wastewater treatment.

According to a recent market research report by Grand View Research, the global industrial filtration market is projected to reach USD 40.55 billion by 2027,

with a significant portion attributed to wire mesh filter technology due to its durability, reusability, and ability to withstand harsh environments.

These filters not only enhance the separation of solids from liquids and gases but also contribute to reduced maintenance costs and increased system longevity.

Therefore, understanding the unique benefits of wire mesh filters is essential for industries aiming to optimize their processes and achieve sustainable practices.

Wire mesh filters have emerged as a vital component in various applications, from chemical processing to wastewater treatment.

According to a recent market research report by Grand View Research, the global industrial filtration market is projected to reach USD 40.55 billion by 2027,

with a significant portion attributed to wire mesh filter technology due to its durability, reusability, and ability to withstand harsh environments.

These filters not only enhance the separation of solids from liquids and gases but also contribute to reduced maintenance costs and increased system longevity.

Therefore, understanding the unique benefits of wire mesh filters is essential for industries aiming to optimize their processes and achieve sustainable practices.

How to Choose the Right Wire Mesh Filter for Your Industrial Needs

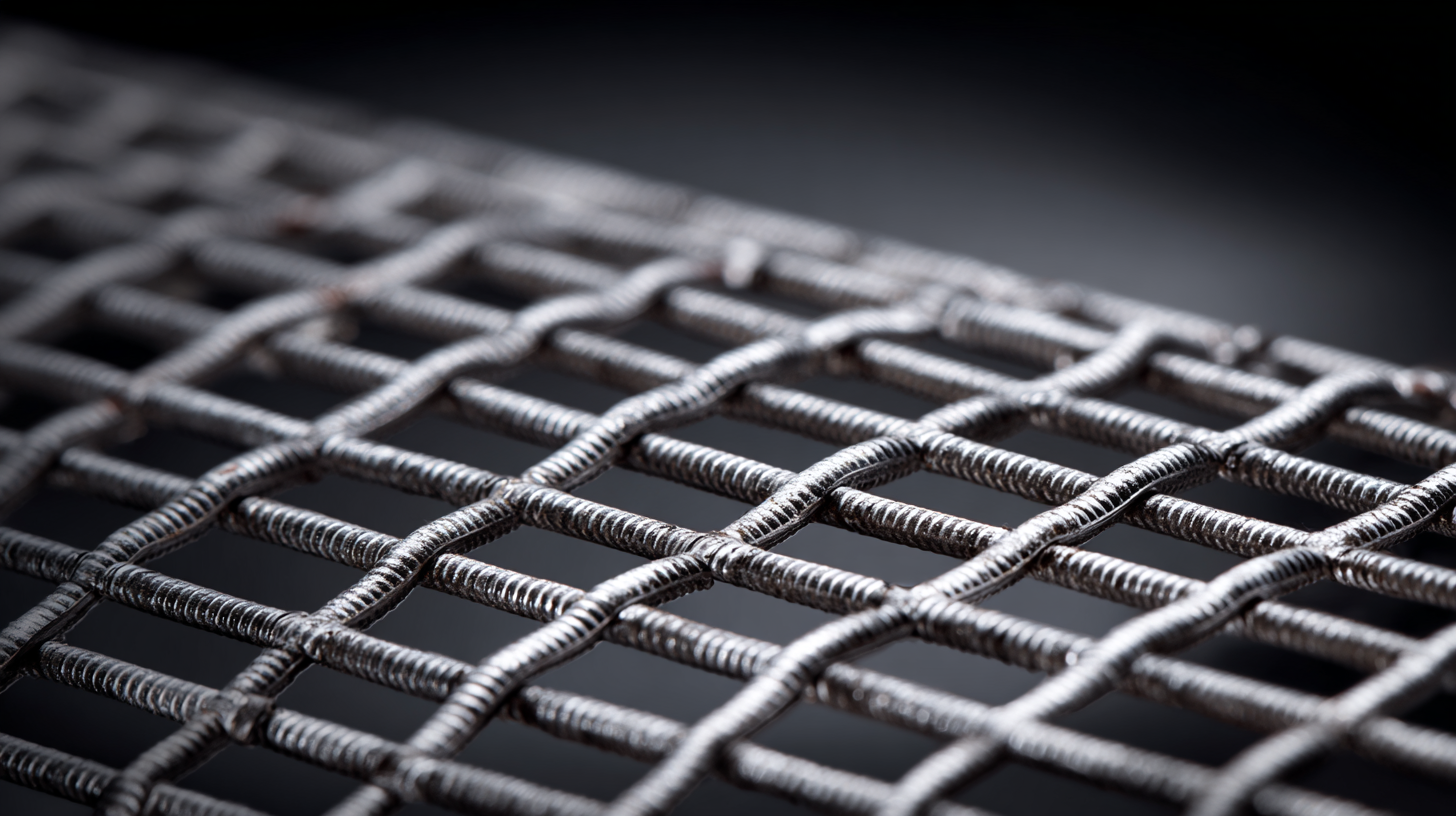

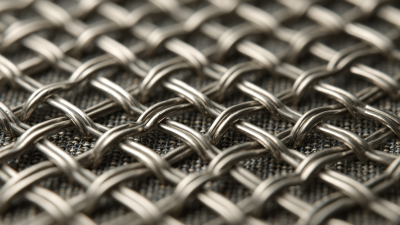

When selecting a wire mesh filter for industrial applications, it is essential to consider various factors to ensure optimal performance and efficiency. Depending on the specific requirements of your operation, factors such as material type, mesh size, and durability will play a crucial role in your decision-making process. Wire mesh filters can be made from various metals, with stainless steel being a popular choice due to its resistance to corrosion and high temperatures.

The market for wire mesh filters is projected to grow significantly, paralleling the broader industrial filtration market, which is estimated to reach a remarkable value by 2033. For instance, the demand for indoor air quality solutions is expected to rise from $15.59 billion in 2025 to $27.03 billion by 2033, indicating an increasing focus on effective filtration systems in manufacturing and other sectors. Additionally, with trends indicating a compound annual growth rate (CAGR) of approximately 2.57% for various filtration media, industries that leverage wire mesh filters can anticipate both demand and innovation in filtration technology. Choosing the right filter not only ensures compliance with safety standards but can also enhance productivity and reduce operational costs.

Understanding the Benefits of Wire Mesh Filters in Industrial Applications

The chart above illustrates the key performance metrics of wire mesh filters used in industrial applications. It highlights factors such as filtration efficiency, durability, cost effectiveness, maintenance frequency, and temperature resistance, providing a comprehensive overview for selecting the right filter for industrial needs.

How to Assess the Filtering Efficiency of Wire Mesh Filters

When evaluating the filtering efficiency of wire mesh filters in industrial applications, several key factors come into play. Firstly, the mesh size is crucial; it determines the particle retention capability of the filter. According to a study by the Filtration Society, a well-chosen mesh size can retain particles as small as 50 microns, making wire mesh filters suitable for a variety of applications, from food processing to chemical manufacturing.

Another significant aspect to assess is the flow rate. Research indicates that wire mesh filters, due to their open structure, maintain a high flow rate even as they capture contaminants. In a report by the Industrial Filtration Association, it was noted that wire mesh filters can achieve flow rates up to 100 liters per minute per square meter while maintaining an efficiency of over 90% in removing larger particles, emphasizing their effectiveness in continuous operations.

Additionally, the material composition of the wire mesh itself influences durability and resistance to corrosion, which in turn affects filtration longevity. A recent market analysis identified that stainless steel wire mesh outperforms other materials in durability, making it an optimal choice for high-demand environments. Thus, when selecting wire mesh filters, it is essential to consider these characteristics for optimal filtration efficiency.

How to Maintain and Clean Wire Mesh Filters for Longevity

Wire mesh filters play a crucial role in various industrial applications, particularly in maintaining the cleanliness and efficiency of fluid systems. To ensure these filters perform optimally and enjoy a long service life, proper maintenance and cleaning practices must be followed. Regular inspection is vital; any buildup of debris or contamination can hinder the filter's effectiveness and lead to more extensive damage to machinery.

Cleaning wire mesh filters involves a few simple steps. First, the filter should be removed from its housing and inspected for visible signs of wear or damage. Using a high-pressure water washer or compressed air can effectively dislodge dirt and particles trapped within the mesh. For more stubborn residues, soaking in a cleaning solution may be necessary. It is essential to conduct these maintenance practices regularly to prevent flow restrictions and to promote efficient operation.

Considering the growing market for rotating oil filters, projected to reach $8.3 billion by 2030, the demand for reliable and well-maintained wire mesh filters will undoubtedly continue to rise alongside industrial advancements.

How to Integrate Wire Mesh Filters into Existing Industrial Systems

Integrating wire mesh filters into existing industrial systems offers a myriad of benefits, primarily focusing on enhanced filtration efficiency and operational reliability. When introducing these filters, it's essential to assess the current system layout and identify key areas where particles and contaminants may pose a risk. The filters can be strategically placed in pipelines, machinery inlets, or fluid reservoirs to effectively capture debris and prevent damage to sensitive components.

To facilitate the installation of wire mesh filters, industries should consider their size and mesh density based on the specific application requirements. For instance, finer mesh filters can be used in systems dealing with smaller particulate contaminants, while coarser filters might suffice for larger debris. Additionally, the integration process should include routine maintenance protocols to ensure optimal performance. This could involve regular inspections and cleanings to prevent blockages and prolong the lifespan of both the filters and the overall system, ultimately leading to increased productivity and reduced operational costs.

How to Evaluate the Cost-Effectiveness of Using Wire Mesh Filters

Evaluating the cost-effectiveness of wire mesh filters in industrial applications involves several key factors. First, it is essential to consider the initial investment versus long-term savings. Wire mesh filters are durable and often require less frequent replacement compared to other filtration options, which can lead to significant cost savings over time. By assessing the lifespan and maintenance requirements, industries can determine the true value of integrating wire mesh solutions into their operations.

Additionally, performance metrics play a crucial role in evaluating cost-effectiveness. Optimal filtration efficiency can reduce downtime and the need for additional equipment, which directly impacts operational costs. By analyzing how well wire mesh filters retain particulates and maintain fluid flow rates, companies can make informed decisions regarding their filtration systems. The total cost of ownership, factoring in purchase price, maintenance, and efficiency, ultimately influences the choice of filtration technology in an industrial setting.

Understanding the Benefits of Wire Mesh Filters in Industrial Applications

| Application Area | Filter Type | Cost per Unit ($) | Efficiency (%) | Maintenance Frequency (Months) | Expected Lifespan (Years) |

|---|---|---|---|---|---|

| Food & Beverage | Stainless Steel | 50 | 95 | 6 | 10 |

| Pharmaceuticals | Bronze | 75 | 98 | 12 | 8 |

| Chemical Processing | Carbon Steel | 40 | 90 | 3 | 5 |

| Oil & Gas | Monel | 90 | 97 | 18 | 15 |

Related Posts

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

The Ultimate Guide to Choosing Stainless Mesh for Industrial Applications and Filtration Efficiency

-

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025