Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

In today's rapidly evolving industrial landscape, the utilization of wire mesh screens has become an indispensable facet across various sectors. According to a recent report by MarketsandMarkets, the global wire mesh market is projected to reach $11.2 billion by 2025, growing at a CAGR of 5.1% from 2020. This growth underscores the critical role that wire mesh screens play in applications ranging from filtration and separation to reinforcement and protection.

Industries such as agriculture, mining, and construction increasingly rely on these versatile tools to enhance productivity and efficiency. The inherent benefits of wire mesh screens, including durability, adaptability, and cost-effectiveness, are enabling industries to innovate and streamline processes, thus paving the way for advancements in technology and materials. This article aims to explore the various benefits and applications of wire mesh screens, shedding light on their relevance in modern manufacturing and construction practices.

Benefits of Wire Mesh Screens in Enhancing Industrial Filtration Processes

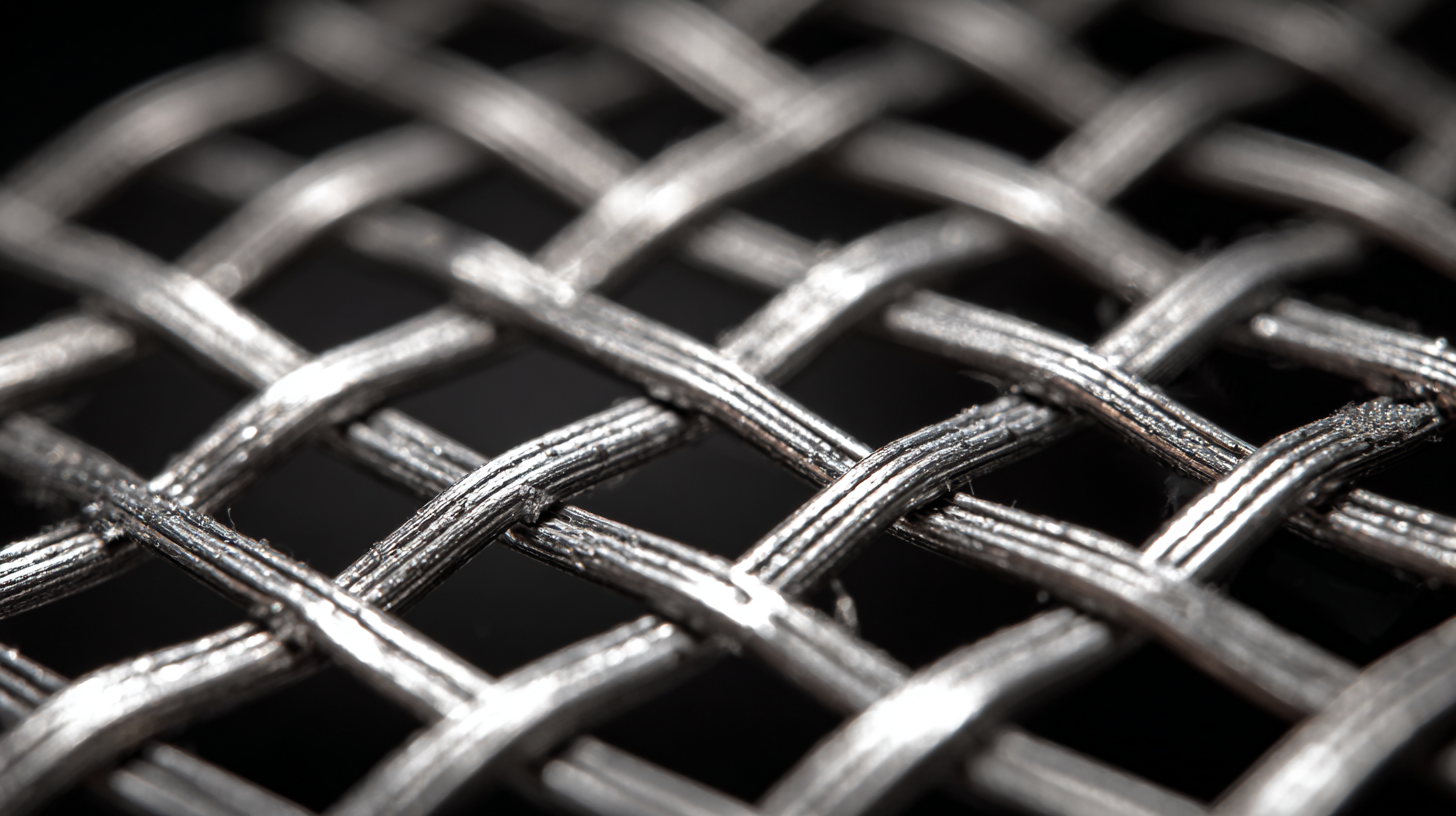

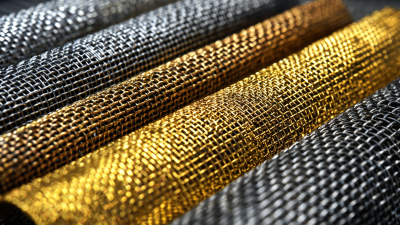

Wire mesh screens play a critical role in enhancing industrial filtration processes across various sectors. Their structural design, consisting of interwoven metal wires, allows for effective filtration of liquids and gases while maintaining high flow rates. This characteristic makes them particularly beneficial in industries such as water treatment, pharmaceuticals, and food processing, where precise separation of particulates is essential for product quality and safety.

Moreover, wire mesh screens are versatile and customizable, which enables them to meet the specific requirements of different applications. They can be manufactured in various sizes and mesh configurations, allowing industries to select the optimal screen for their filtration needs. The durability and resistance to corrosion of materials like stainless steel further enhance their longevity, reducing downtime and maintenance costs. This combination of efficiency and adaptability ensures that wire mesh screens significantly improve the overall effectiveness of filtration systems in modern industrial settings.

Improving Material Handling Efficiency with Wire Mesh Screens in Manufacturing

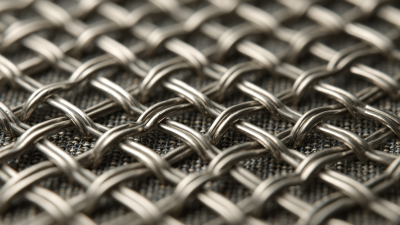

Wire mesh screens are becoming integral to manufacturing processes, significantly enhancing material handling efficiency. According to a report from the Industrial Supply Association, using wire mesh products can reduce material handling time by up to 30%, leading to increased productivity and lower operational costs. These screens are versatile, allowing for the effective sorting, filtering, and conveying of materials across various industries. For instance, in food processing, wire mesh screens ensure hygiene while allowing for efficient grain separation, optimizing resource utilization.

Tips for implementing wire mesh screens include selecting the appropriate mesh size to match your material properties, ensuring compatibility with your existing handling systems. Regular maintenance is also crucial; a cleaning schedule can prevent clogging and prolong the lifespan of your screens. In a study published by the American Society of Mechanical Engineers, facilities that adopted preventive maintenance protocols for wire mesh systems reported a 25% decrease in downtime, highlighting the importance of proactive care in material handling setups.

Incorporating wire mesh screens not only boosts efficiency but also contributes to enhanced safety during material handling. Their robust structure can support heavy loads while minimizing risks of material overflow. According to a safety audit from OSHA, companies utilizing wire mesh systems reported fewer material handling accidents, underscoring their role in promoting a secure working environment.

Applications of Wire Mesh Screens in the Food and Beverage Industry: Standards and Compliance

Wire mesh screens play a pivotal role in the food and beverage industry, ensuring compliance with stringent safety and quality standards. According to the Food and Drug Administration (FDA), more than 48 million Americans suffer from foodborne illnesses each year. With such alarming statistics, using wire mesh screens for filtering and separation processes becomes essential.

These screens are crucial for avoiding contamination during the production stages, as they help remove impurities while allowing for efficient processing. The use of wire mesh complies with regulations set by entities such as the FDA and the U.S. Department of Agriculture (USDA), guaranteeing that businesses maintain the highest hygiene standards.

These screens are crucial for avoiding contamination during the production stages, as they help remove impurities while allowing for efficient processing. The use of wire mesh complies with regulations set by entities such as the FDA and the U.S. Department of Agriculture (USDA), guaranteeing that businesses maintain the highest hygiene standards.

Tips: When selecting wire mesh screens for food applications, ensure they are made from food-grade materials such as stainless steel, which are resistant to corrosion and easier to clean. Regular maintenance and inspections can also prevent potential contamination issues.

In applications such as brewing and food packaging, wire mesh screens are utilized not only for filtration but also for preservation. According to a report by Grand View Research, the global mesh screen market is expected to reach $1.2 billion by 2025, highlighting an increasing trend toward automation and efficiency in food processing. Embracing these technologies can significantly enhance product quality and operational efficiency, staying compliant with ever-evolving industry standards.

Tips: Always verify the mesh size to ensure it meets the specific filtration needs of your production process, as this directly impacts the quality of your final product. Regular training of employees on proper handling techniques can further minimize contamination risks.

The Role of Wire Mesh Screens in Environmental Protection and Waste Management

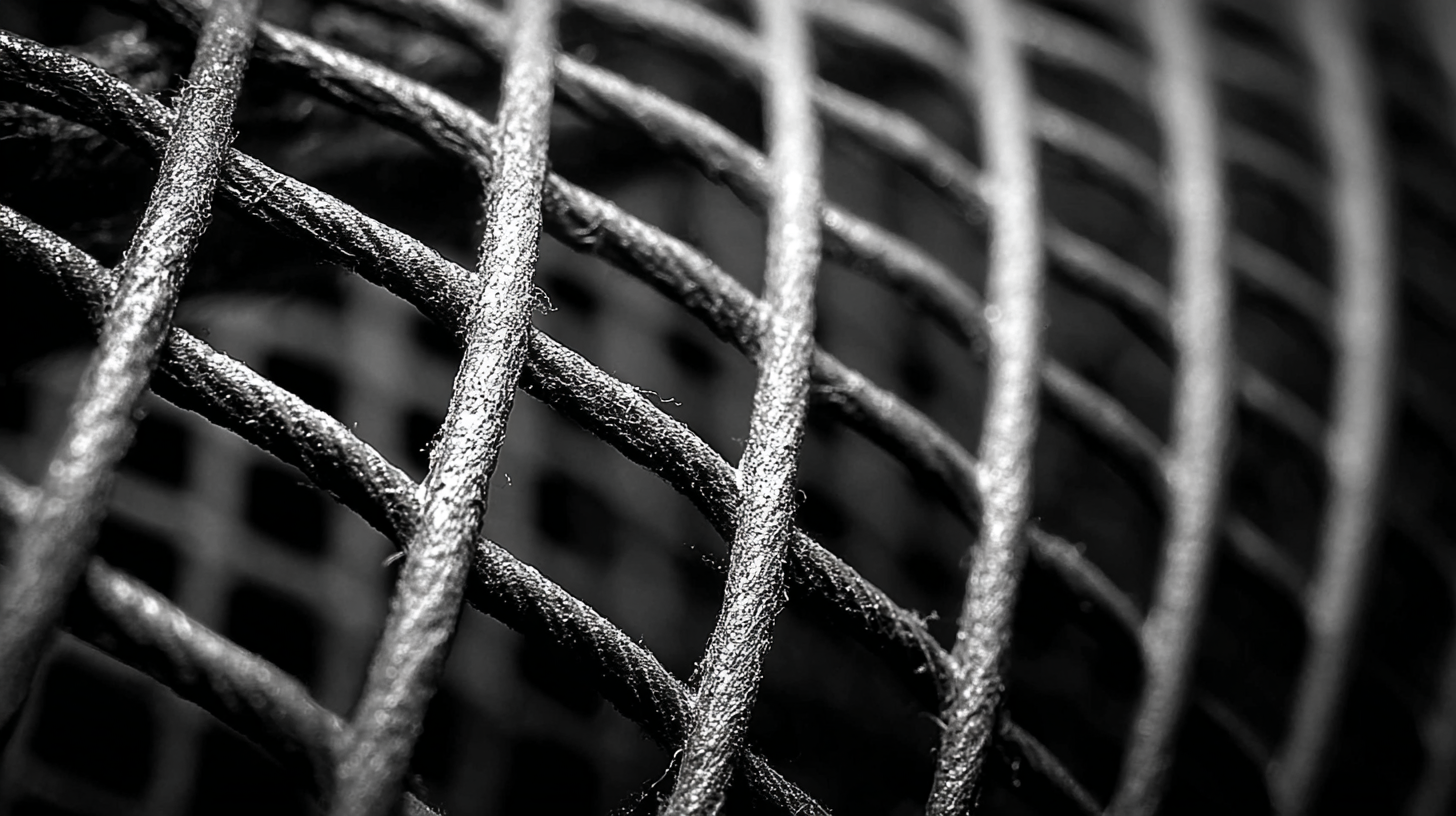

Wire mesh screens play a crucial role in environmental protection and waste management by enhancing the efficiency of filtration and separation processes. These screens are engineered to effectively capture solid particles while allowing liquids and gases to pass through, making them essential in various waste treatment applications. In the recycling industry, wire mesh screens are used to separate recyclable materials from waste streams, ensuring that valuable resources are recovered and diverted from landfills. This process not only reduces environmental impact but also promotes sustainable practices by maximizing resource recovery.

Additionally, wire mesh screens are vital in water and wastewater treatment facilities. They act as primary barriers to prevent debris and larger contaminants from entering treatment systems, which protects equipment and ensures compliance with environmental regulations. By filtering out harmful substances, these screens help safeguard aquatic ecosystems and public health. The versatility and durability of wire mesh screens make them indispensable in ongoing efforts to promote a cleaner and more sustainable environment, solidifying their importance in modern industrial applications.

Cost-Effectiveness of Wire Mesh Screens Compared to Traditional Screening Solutions in Industries

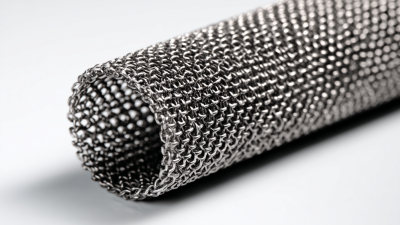

Wire mesh screens have become an essential component in modern industry due to their cost-effectiveness compared to traditional screening solutions. Industries, particularly those in manufacturing and materials processing, are increasingly recognizing that wire mesh screens not only offer enhanced durability and performance but also significant savings in operational costs. For instance, their reusable nature and resistance to wear-and-tear reduce the frequency of replacement, thereby minimizing downtime and expenses associated with maintenance.

Moreover, advancements in technologies such as screen-printing in the photovoltaics industry highlight the versatility of wire mesh screens. They provide unique design flexibility and compatibility with various functional layers while supporting large-scale manufacturing. As industries strive for efficiency, integrating innovative materials and techniques, such as those seen in the evolution of textile printing and sustainable manufacturing solutions, further reinforces the value of wire mesh screens. This adaptability makes them a preferred choice in sectors adopting modern approaches to production, ultimately ensuring that businesses remain competitive in a rapidly evolving market.

Cost-Effectiveness of Wire Mesh Screens Compared to Traditional Screening Solutions

This chart illustrates the cost comparison between wire mesh screens and traditional screening solutions in various industries. The data represent average costs for purchasing and maintaining these screening solutions, highlighting the cost-effectiveness of wire mesh screens.

Related Posts

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs

-

Unlocking the Versatility of Fine Wire Mesh: Applications You Didn't Know About!

-

How to Choose the Right Stainless Mesh for Your Specific Applications

-

The Ultimate Guide to Choosing the Right Stainless Steel Cable for Your Project

-

How to Choose the Right Metal Mesh for Your Industrial Applications

-

How to Choose the Perfect Fireplace Screen for Your Home Decor