What is Aluminum Woven Wire Mesh and Its Applications in Various Industries

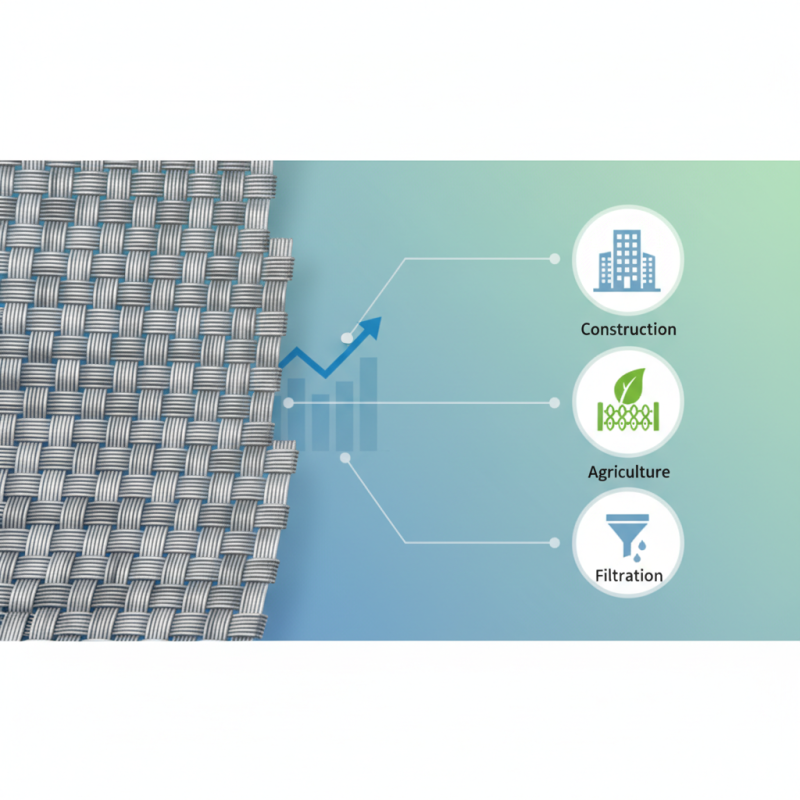

Aluminum woven wire mesh is a versatile and lightweight material that has gained significant traction across various industries due to its exceptional properties and functional benefits. According to market research, the global aluminum wire mesh market is anticipated to grow at a CAGR of approximately 6.2% between 2021 and 2026, indicative of its increasing adoption in sectors such as construction, agriculture, and filtration. The unique characteristics of aluminum woven wire mesh, including its corrosion resistance, high strength-to-weight ratio, and adaptability, make it an ideal choice for a wide array of applications.

In the construction industry, aluminum woven wire mesh is utilized for reinforcing concrete structures while providing ventilation and aesthetic value. Its role in the agricultural sector is equally vital, serving as a protective barrier against pests while facilitating proper air circulation. Additionally, in filtration applications, aluminum woven wire mesh is employed for separating particles from fluids, showcasing its effectiveness in various industrial processes. The ability to be tailored to specific requirements further enhances its appeal, cementing aluminum woven wire mesh as an invaluable resource across multiple fields. As industries continue to innovate and evolve, the demand for aluminum woven wire mesh is poised for sustained growth, reiterating its significance in modern manufacturing and construction practices.

What is Aluminum Woven Wire Mesh?

Aluminum woven wire mesh is a versatile material characterized by its lightweight yet durable properties, making it an ideal choice for various industrial applications. This mesh is created by interlacing aluminum wires in a patterned design, which enhances its strength while maintaining flexibility. Its corrosion resistance is particularly significant, as aluminum naturally forms a protective oxide layer, enabling the mesh to withstand harsh environmental conditions. According to a recent market analysis report, the aluminum mesh market is projected to grow at a CAGR of approximately 4.5% between 2023 and 2030, indicating increased demand across several sectors.

The applications of aluminum woven wire mesh span a broad spectrum of industries including construction, agriculture, and mining. In construction, it is often utilized for architectural features, safety screens, and HVAC systems due to its lightweight nature and aesthetic appeal. In agriculture, this mesh type serves as a protective barrier against pests while allowing air and light to pass through, thereby supporting plant growth. The mining industry also employs aluminum mesh for filtration and support purposes, benefiting from its non-corrosive properties which enhance longevity and reliability.

With the projected growth in the aluminum mesh market, its role in various applications is expected to become even more prominent, driven by innovations and improved manufacturing techniques.

Properties and Characteristics of Aluminum Woven Wire Mesh

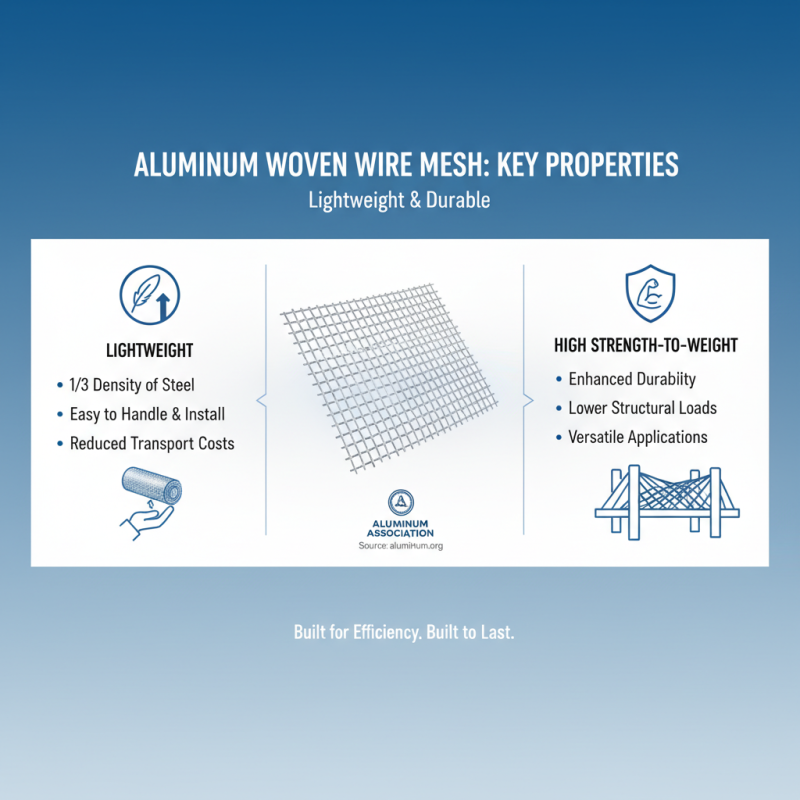

Aluminum woven wire mesh is renowned for its remarkable properties, which make it a versatile choice across various industries. One of the key characteristics is its lightweight nature; aluminum is significantly lighter than steel, which allows for ease of handling and installation. According to the Aluminum Association, aluminum has one-third the density of steel, making products fabricated from aluminum easier to transport and work with. Furthermore, aluminum's high strength-to-weight ratio enhances durability while maintaining lower structural loads, contributing to overall efficiency in design applications.

Corrosion resistance is another crucial property of aluminum woven wire mesh, stemming from its natural oxide layer that protects it from environmental factors. A study by the International Aluminum Institute emphasizes that aluminum can resist corrosive elements in environments such as coastal areas, where saltwater exposure is prevalent. This resistance ensures longevity and reduced maintenance costs, especially in industries like construction and manufacturing. Additionally, the mesh's versatility in design and flexibility allows for varied applications, from architectural facades to filtration systems, showcasing its adaptability to meet specific industry needs. As metal mesh solutions continue to evolve, the performance data backing aluminum’s properties illustrates its growing importance in sectors aiming for both innovation and sustainability.

Common Applications in the Construction Industry

Aluminum woven wire mesh is increasingly recognized for its versatility and durability, making it a preferred choice in the construction industry. This lightweight yet robust material is commonly used for various applications, including safety barriers, reinforcement in concrete, and as a component in architectural facades. According to a report by the Freedonia Group, the demand for metal mesh, including aluminum varieties, is projected to grow at an annual rate of 4.7% through 2025, driven by the expanding construction sector and advancements in building techniques.

In construction, aluminum woven wire mesh is often utilized for window screens, which provide ventilation while keeping insects at bay. Its corrosion resistance and longevity are critical factors, especially in environments with high humidity and exposure to elements. Furthermore, the mesh is used in concrete applications, such as in concrete slabs for added tensile strength, helping to minimize cracking and extending the life of structures. The Global Concrete Reinforcement Market report indicates that the market size is set to reach $218 billion by 2027, which emphasizes the growing reliance on materials like aluminum mesh for enhancing structural integrity.

Another significant application of aluminum woven wire mesh in construction is in acoustical panels and ceilings, where it aids in sound dampening. This feature is particularly valuable in urban developments, where controlling noise pollution is increasingly important. The expansion of urban areas has led to a heightened focus on noise control measures in architectural design, further solidifying aluminum mesh's place in modern construction practices. As sustainable building practices gain traction, the recyclable nature of aluminum also positions it as a material of choice in eco-friendly construction projects.

What is Aluminum Woven Wire Mesh and Its Applications in Various Industries

| Application Area | Description | Benefits |

|---|---|---|

| Construction | Used for reinforcement in concrete and masonry structures. | Enhances structural integrity and durability. |

| Architectural | Used for decorative facades and modern building designs. | Adds aesthetic value and flexibility in design. |

| Infrastructure | Applications in bridge and highway construction for safety barriers. | Improves safety and reduces maintenance costs. |

| Fencing | Used for security fencing in residential and commercial properties. | Provides visibility while ensuring security. |

| Industrial | Used in machinery guards and screens. | Protects workers from hazards and improves productivity. |

| HVAC Systems | Used as filters in heating, ventilation, and air conditioning systems. | Enhances air quality and system efficiency. |

| Environmental | Applications in water treatment and filtration systems. | Improves water quality and sustainability. |

Role of Aluminum Woven Wire Mesh in the Food Processing Sector

Aluminum woven wire mesh is rapidly gaining recognition in the food processing sector due to its lightweight, corrosion resistance, and excellent mechanical properties. According to a report by the Research and Markets, the global aluminum mesh market is expected to grow at a CAGR of 5.6% from 2023 to 2028, driven by the increasing demand for hygienic and durable materials in food production environments. This type of mesh is ideal for applications such as filtration, sieving, and support structures, ensuring that food products meet the strict safety and quality standards set by regulatory bodies.

In addition to its durability, aluminum woven wire mesh provides significant benefits for maintaining sanitary conditions in food processing plants. Its non-reactive nature prevents contamination, making it an excellent choice for applications that require direct contact with food products. The mesh allows for optimal air and liquid flow, enhancing the efficiency of drying and processing while minimizing the risk of bacterial growth. Industry studies have shown that using aluminum mesh in filtration systems can reduce the incidence of particulate contamination by up to 40%, which is critical for maintaining food safety and quality assurance in production lines.

Advantages of Using Aluminum Woven Wire Mesh in Environmental Filters

Aluminum woven wire mesh has emerged as a preferred choice in environmental filter applications due to its unique combination of durability, lightweight properties, and resistance to corrosion. The mesh structure allows for efficient filtration, capturing particulate matter while maintaining high airflow rates. This makes it particularly valuable in industries like water treatment, air filtration, and even in the manufacturing of filtration systems for various gases. Its longevity and recyclability further enhance its appeal, aligning well with sustainable practices in industrial processes.

When utilizing aluminum woven wire mesh for environmental filters, consider its mesh density and design. A denser mesh can offer finer filtration, but may also restrict airflow. It's crucial to balance these factors based on specific filtration needs. Regular maintenance is also key to ensure optimal performance; check for any accumulated debris and clean the mesh periodically to maintain its efficiency.

Incorporating aluminum woven wire mesh into construction and environmental frameworks not only provides excellent filtration but also contributes to a lighter and more sustainable product. This dual functionality supports various applications ranging from HVAC systems to outdoor air filtration units, showcasing the versatility and environmental advantages of aluminum mesh.

Related Posts

-

Top 10 Essential Tips for Choosing the Right Wire & Cable for Your Projects

-

Exploring the Benefits and Applications of Wire Mesh Screens in Modern Industry

-

Understanding the Versatility and Applications of Steel Wire Mesh in Modern Construction

-

Exploring the Impact of Metal Screen Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Wire Products: Insights and Trends from China's 138th Canton Fair 2025

-

The Ultimate Guide to Choosing the Right Wire Mesh Products for Your Needs